TOC

TOC

INSTALLATION |

INPUT RECONNECT PROCEDURE

On multiple input voltage welders, be sure the machine is connected per the following instructions for the volt- age being supplied to the welder.

![]() CAUTION

CAUTION

Failure to follow these instructions can cause immedi- ate failure of components within the welder and void machine’s warranty.

Multiple voltage models are shipped connected for the highest voltage. To change this connection refer to the following instructions.

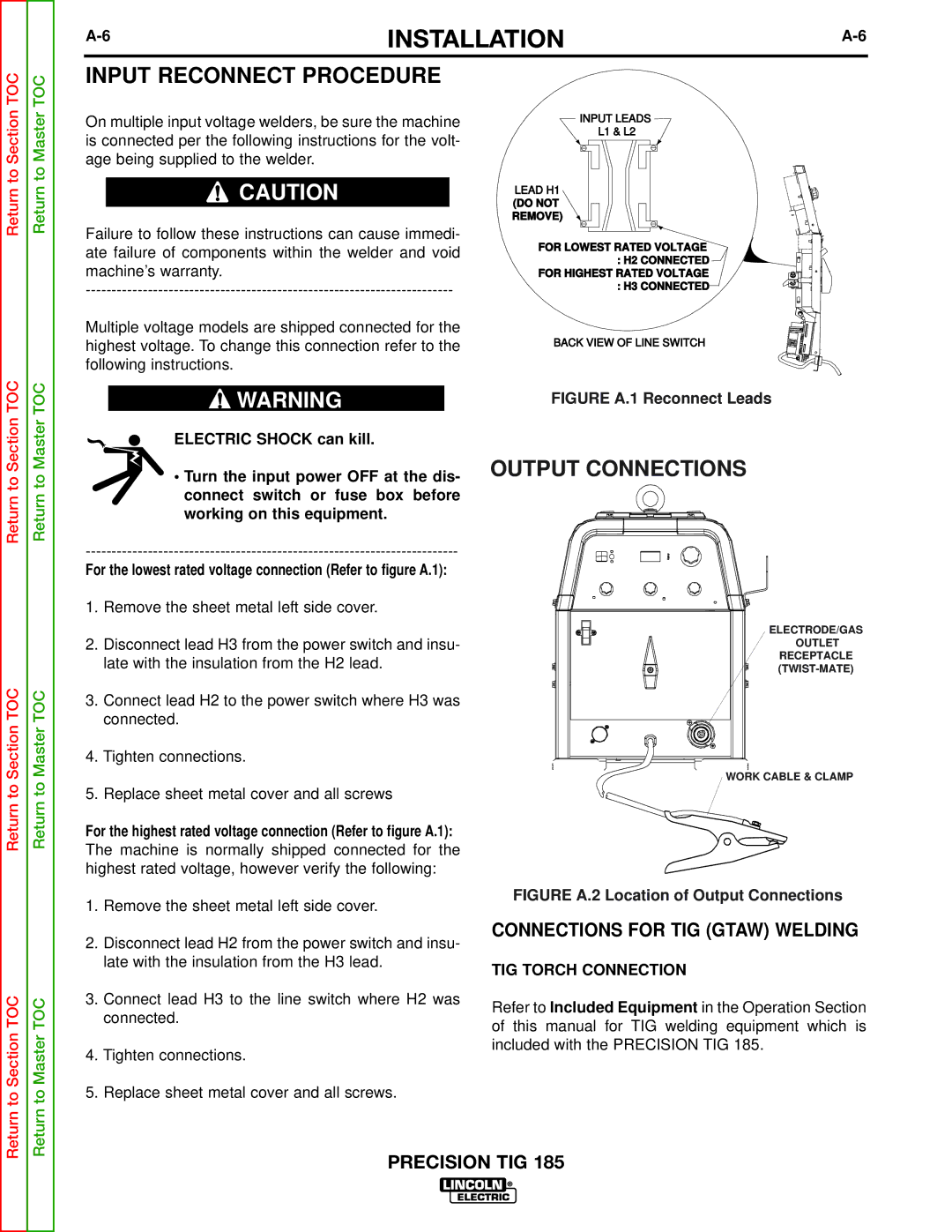

INPUT LEADS

L1 & L2

LEAD H1 (DO NOT REMOVE)

FOR LOWEST RATED VOLTAGE : H2 CONNECTED FOR HIGHEST RATED VOLTAGE : H3 CONNECTED

BACK VIEW OF LINE SWITCH

Return to Section TOC

to Section TOC

Return to Master TOC

to Master TOC

![]() WARNING

WARNING

ELECTRIC SHOCK can kill.

•Turn the input power OFF at the dis- connect switch or fuse box before working on this equipment.

For the lowest rated voltage connection (Refer to figure A.1):

1.Remove the sheet metal left side cover.

2.Disconnect lead H3 from the power switch and insu- late with the insulation from the H2 lead.

3.Connect lead H2 to the power switch where H3 was connected.

4.Tighten connections.

5.Replace sheet metal cover and all screws

FIGURE A.1 Reconnect Leads

OUTPUT CONNECTIONS

ELECTRODE/GAS

OUTLET

RECEPTACLE

WORK CABLE & CLAMP

For the highest rated voltage connection (Refer to figure A.1): The machine is normally shipped connected for the highest rated voltage, however verify the following:

1.Remove the sheet metal left side cover.

2.Disconnect lead H2 from the power switch and insu- late with the insulation from the H3 lead.

3.Connect lead H3 to the line switch where H2 was connected.

4.Tighten connections.

FIGURE A.2 Location of Output Connections

CONNECTIONS FOR TIG (GTAW) WELDING

TIG TORCH CONNECTION

Refer to Included Equipment in the Operation Section of this manual for TIG welding equipment which is included with the PRECISION TIG 185.

Return to

Return to

5. Replace sheet metal cover and all screws.

PRECISION TIG 185