Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

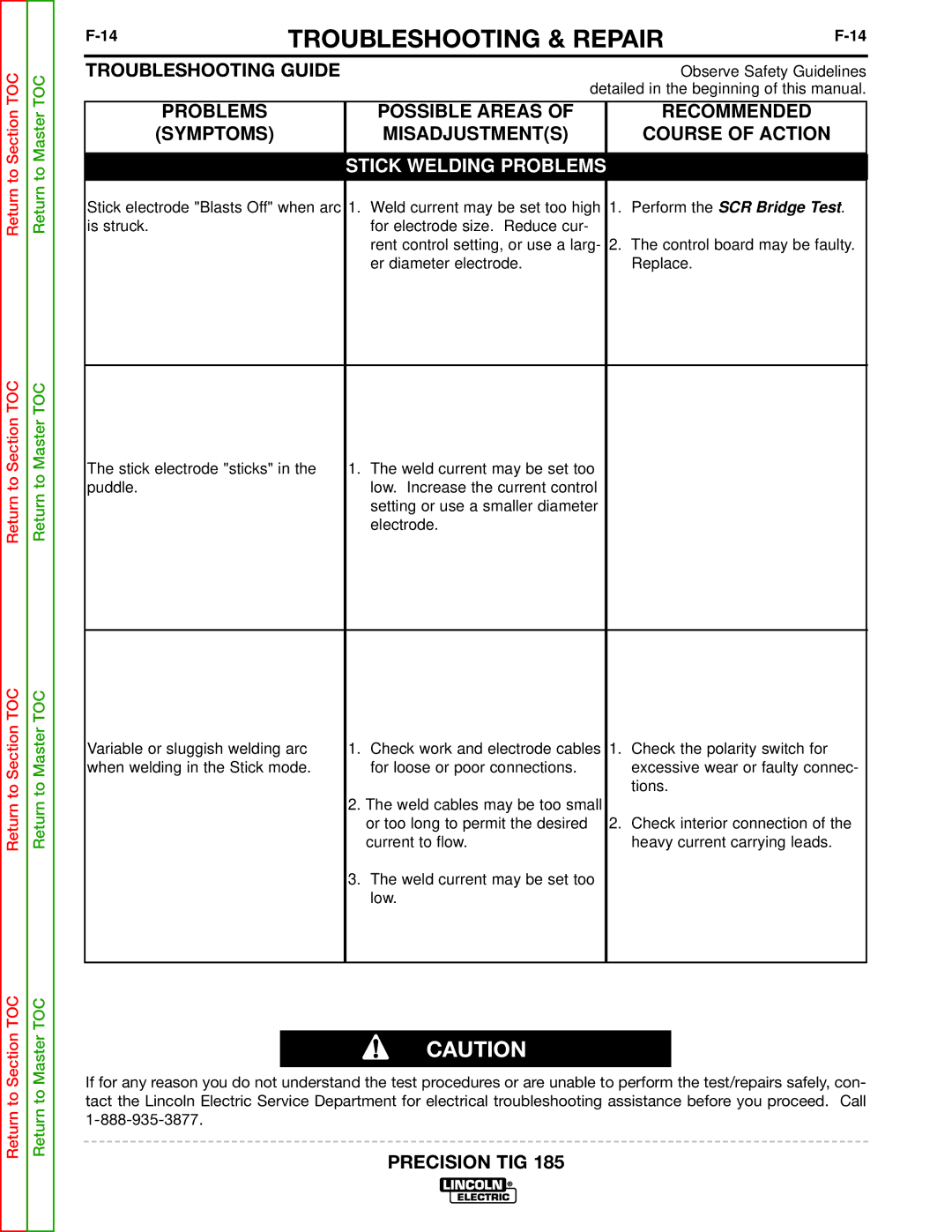

TROUBLESHOOTING & REPAIR | |||||

TROUBLESHOOTING GUIDE |

| Observe Safety Guidelines | |||

|

| detailed in the beginning of this manual. | |||

|

|

|

|

|

|

PROBLEMS |

| POSSIBLE AREAS OF |

| RECOMMENDED |

|

(SYMPTOMS) |

| MISADJUSTMENT(S) |

| COURSE OF ACTION |

|

|

|

|

|

|

|

|

| STICK WELDING PROBLEMS |

|

|

|

Stick electrode "Blasts Off" when arc 1. Weld current may be set too high | 1. | Perform the SCR Bridge Test. | |||

is struck. |

| for electrode size. Reduce cur- |

|

|

|

|

| rent control setting, or use a larg- | 2. | The control board may be faulty. | |

|

| er diameter electrode. |

| Replace. |

|

The stick electrode "sticks" in the | 1. The weld current may be set too |

puddle. | low. Increase the current control |

| setting or use a smaller diameter |

| electrode. |

Variable or sluggish welding arc | 1. | Check work and electrode cables 1. | Check the polarity switch for |

when welding in the Stick mode. |

| for loose or poor connections. | excessive wear or faulty connec- |

|

|

| tions. |

| 2. The weld cables may be too small |

| |

|

| or too long to permit the desired 2. | Check interior connection of the |

|

| current to flow. | heavy current carrying leads. |

| 3. | The weld current may be set too |

|

|

| low. |

|

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, con- tact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call