Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

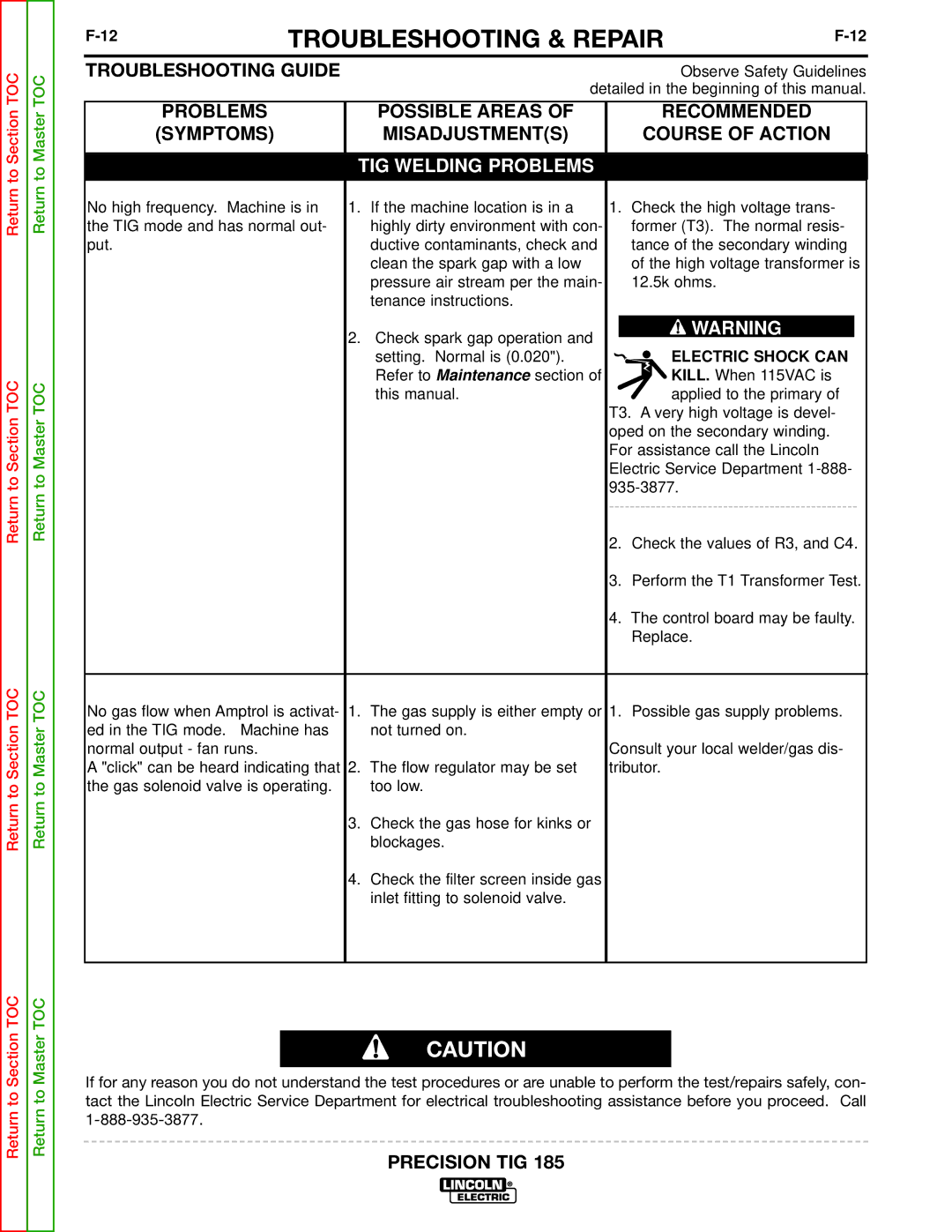

TROUBLESHOOTING & REPAIR | ||||||||

TROUBLESHOOTING GUIDE |

|

|

|

| Observe Safety Guidelines | |||

|

| detailed in the beginning of this manual. | ||||||

|

|

|

|

|

|

|

|

|

| PROBLEMS | POSSIBLE AREAS OF |

|

| RECOMMENDED |

|

| |

| (SYMPTOMS) | MISADJUSTMENT(S) |

|

| COURSE OF ACTION |

|

| |

|

|

|

|

|

|

|

|

|

|

| TIG WELDING PROBLEMS |

|

|

|

|

|

|

No high frequency. Machine is in | 1. If the machine location is in a | 1. Check the high voltage trans- | ||||||

the TIG mode and has normal out- | highly dirty environment with con- |

|

| former (T3). The normal resis- | ||||

put. |

| ductive contaminants, check and |

|

| tance of the secondary winding | |||

|

| clean the spark gap with a low |

|

| of the high voltage transformer is | |||

|

| pressure air stream per the main- |

|

| 12.5k ohms. |

|

| |

|

| tenance instructions. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 2. Check spark gap operation and |

|

|

| WARNING |

|

|

|

|

|

|

| ELECTRIC SHOCK CAN | |||

|

| setting. Normal is (0.020"). |

|

|

| |||

|

| Refer to Maintenance section of |

|

|

| KILL. When 115VAC is |

|

|

|

| this manual. |

|

|

| applied to the primary of | ||

|

|

|

| T3. A very high voltage is devel- | ||||

|

|

| oped on the secondary winding. |

|

| |||

|

|

| For assistance call the Lincoln |

|

| |||

|

|

| Electric Service Department | |||||

|

|

|

|

| ||||

|

|

| ||||||

|

|

| 2. Check the values of R3, and C4. | |||||

|

|

| 3. Perform the T1 Transformer Test. | |||||

|

|

| 4. The control board may be faulty. | |||||

|

|

|

|

| Replace. |

|

| |

No gas flow when Amptrol is activat- | 1. | The gas supply is either empty or 1. Possible gas supply problems. | |

ed in the TIG mode. Machine has |

| not turned on. |

|

normal output - fan runs. |

|

| Consult your local welder/gas dis- |

A "click" can be heard indicating that | 2. | The flow regulator may be set | tributor. |

the gas solenoid valve is operating. |

| too low. |

|

| 3. | Check the gas hose for kinks or |

|

|

| blockages. |

|

| 4. | Check the filter screen inside gas |

|

|

| inlet fitting to solenoid valve. |

|

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, con- tact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call