Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

OPERATION |

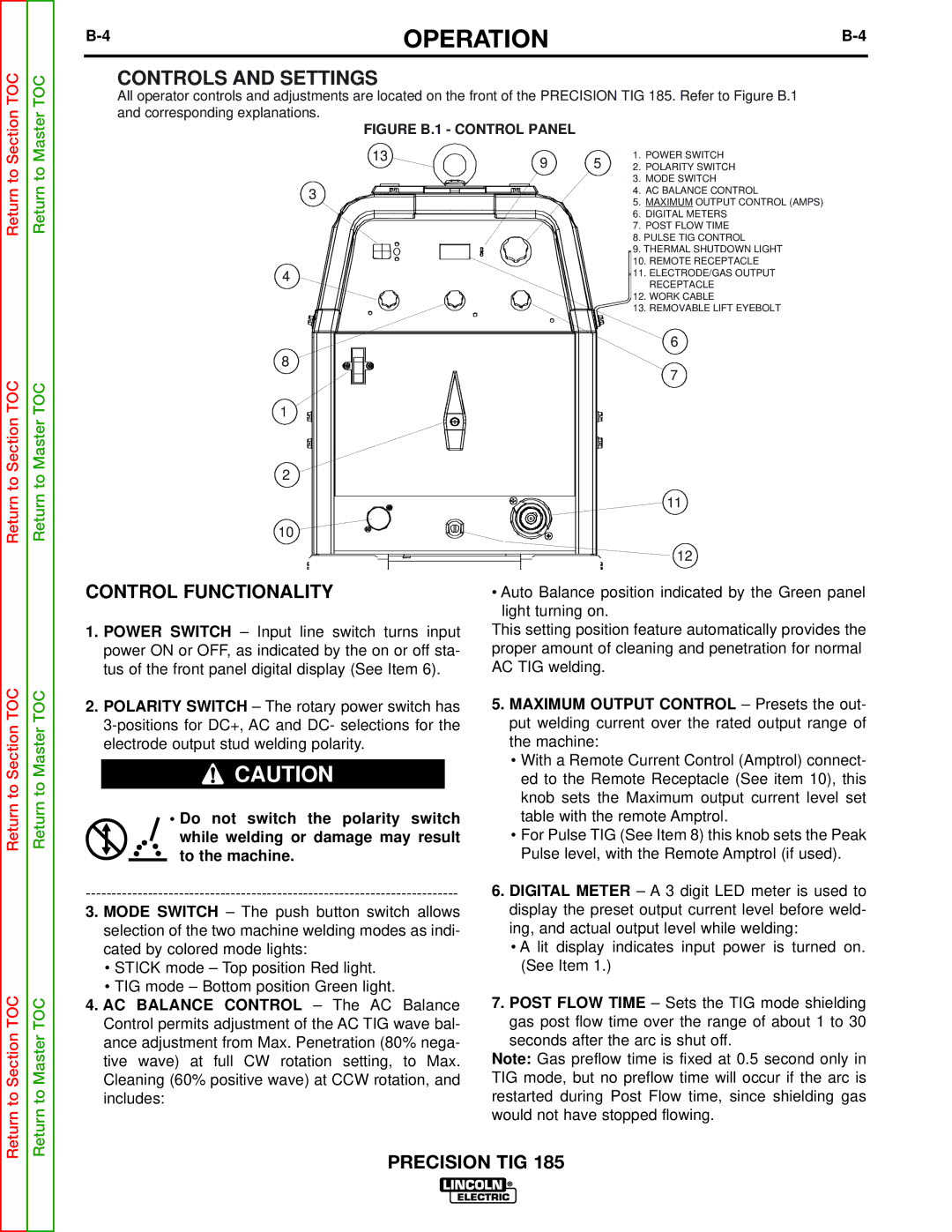

CONTROLS AND SETTINGS

All operator controls and adjustments are located on the front of the PRECISION TIG 185. Refer to Figure B.1 and corresponding explanations.

FIGURE B.1 - CONTROL PANEL

13 | 9 | 5 | 1. | POWER SWITCH |

| 2. | POLARITY SWITCH | ||

|

|

| 3. | MODE SWITCH |

3 |

|

| 4. | AC BALANCE CONTROL |

|

| 5. | MAXIMUM OUTPUT CONTROL (AMPS) | |

|

|

| ||

|

|

| 6. | DIGITAL METERS |

|

|

| 7. | POST FLOW TIME |

| 8. PULSE TIG CONTROL | |

| 9. THERMAL SHUTDOWN LIGHT | |

| 10. REMOTE RECEPTACLE | |

4 | 11. ELECTRODE/GAS OUTPUT | |

RECEPTACLE | ||

| ||

| 12. WORK CABLE | |

| 13. REMOVABLE LIFT EYEBOLT |

6

8

7

1

2

11

10

12

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

CONTROL FUNCTIONALITY

1.POWER SWITCH – Input line switch turns input power ON or OFF, as indicated by the on or off sta- tus of the front panel digital display (See Item 6).

2.POLARITY SWITCH – The rotary power switch has

![]() CAUTION

CAUTION

• Do not switch the polarity switch while welding or damage may result to the machine.

3.MODE SWITCH – The push button switch allows selection of the two machine welding modes as indi- cated by colored mode lights:

•STICK mode – Top position Red light.

•TIG mode – Bottom position Green light.

4.AC BALANCE CONTROL – The AC Balance Control permits adjustment of the AC TIG wave bal- ance adjustment from Max. Penetration (80% nega- tive wave) at full CW rotation setting, to Max. Cleaning (60% positive wave) at CCW rotation, and includes:

•Auto Balance position indicated by the Green panel light turning on.

This setting position feature automatically provides the proper amount of cleaning and penetration for normal AC TIG welding.

5.MAXIMUM OUTPUT CONTROL – Presets the out- put welding current over the rated output range of the machine:

•With a Remote Current Control (Amptrol) connect- ed to the Remote Receptacle (See item 10), this knob sets the Maximum output current level set table with the remote Amptrol.

•For Pulse TIG (See Item 8) this knob sets the Peak Pulse level, with the Remote Amptrol (if used).

6.DIGITAL METER – A 3 digit LED meter is used to display the preset output current level before weld- ing, and actual output level while welding:

•A lit display indicates input power is turned on. (See Item 1.)

7.POST FLOW TIME – Sets the TIG mode shielding

gas post flow time over the range of about 1 to 30 seconds after the arc is shut off.

Note: Gas preflow time is fixed at 0.5 second only in TIG mode, but no preflow time will occur if the arc is restarted during Post Flow time, since shielding gas would not have stopped flowing.