OPERATION |

Return to Master TOC

WELDING IN STICK MODE

1.Put the electrode holder and cable quick connect plug into the electrode output receptacle. Turn clock- wise until tight. Connect the work clamp to the work piece.

2.Set the TIG/STICK switch to “STICK”.

3.Set the Polarity Switch to the weld mode desired for the type of electrode being used (most commonly DC+).

4.Place the electrode in the electrode holder.

![]() WARNING

WARNING

5.Turn the power switch to “ON”.

6.Adjust the Current Control to the desired amps.

7.Strike an arc and weld.

NOTE: When the TIG/STICK switch is set to “STICK” the output is always on when the power switch is on. A remote control has no effect on the welding current and the gas flow and high frequency TIG arc starter are dis- abled.

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

• In Stick Mode the output terminal and electrode will be electrically hot whenever the power switch is turned on.

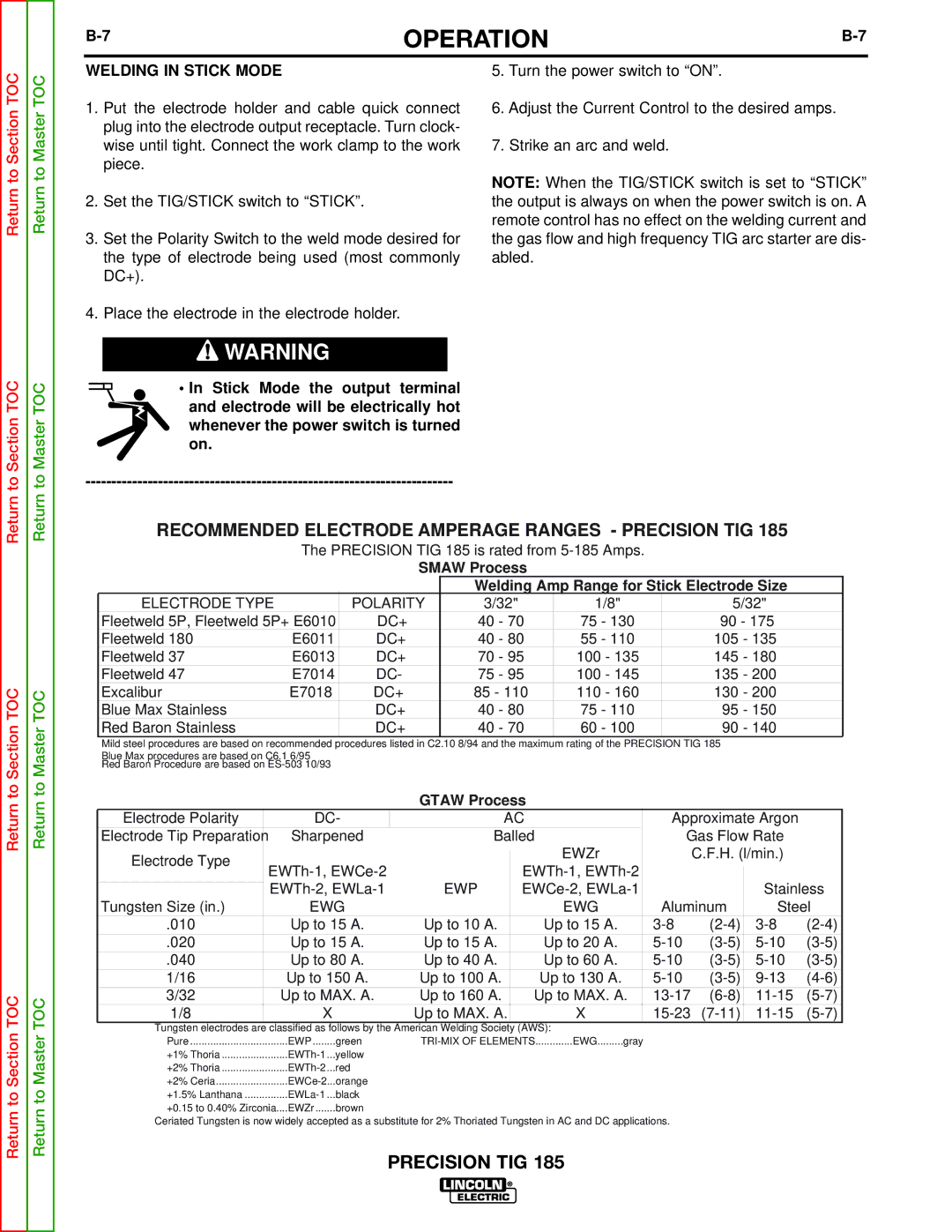

RECOMMENDED ELECTRODE AMPERAGE RANGES - PRECISION TIG 185

The PRECISION TIG 185 is rated from

SMAW Process

|

|

| Welding Amp Range for Stick Electrode Size | |||

ELECTRODE TYPE |

| POLARITY | 3/32" | 1/8" | 5/32" | |

Fleetweld 5P, Fleetweld 5P+ E6010 | DC+ | 40 - 70 | 75 - 130 | 90 - 175 | ||

Fleetweld 180 | E6011 | DC+ | 40 - 80 | 55 - 110 | 105 | - 135 |

Fleetweld 37 | E6013 | DC+ | 70 - 95 | 100 - 135 | 145 | - 180 |

Fleetweld 47 | E7014 | DC- | 75 - 95 | 100 - 145 | 135 | - 200 |

Excalibur | E7018 | DC+ | 85 - 110 | 110 - 160 | 130 | - 200 |

Blue Max Stainless |

| DC+ | 40 - 80 | 75 - 110 | 95 | - 150 |

Red Baron Stainless |

| DC+ | 40 - 70 | 60 - 100 | 90 | - 140 |

Mild steel procedures are based on recommended procedures listed in C2.10 8/94 and the maximum rating of the PRECISION TIG 185

Blue Max procedures are based on C6.1 6/95 Red Baron Procedure are based on

GTAW Process

| Electrode Polarity |

| DC- | AC |

|

| Approximate Argon |

| ||||

| Electrode Tip Preparation |

| Sharpened | Balled |

|

| Gas Flow Rate |

| ||||

| Electrode Type |

|

|

|

|

| EWZr |

|

| C.F.H. (l/min.) |

| |

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

| |||||

|

| EWP |

|

|

| Stainless | ||||||

| Tungsten Size (in.) |

| EWG |

|

| EWG |

| Aluminum | Steel | |||

.010 |

| Up to 15 A. | Up to 10 A. |

| Up to 15 A. |

| ||||||

.020 |

| Up to 15 A. | Up to 15 A. |

| Up to 20 A. |

| ||||||

.040 |

| Up to 80 A. | Up to 40 A. |

| Up to 60 A. |

| ||||||

1/16 |

| Up to 150 A. | Up to 100 A. |

| Up to 130 A. |

| ||||||

3/32 |

| Up to MAX. A. | Up to 160 A. | Up to MAX. A. |

| |||||||

| 1/8 |

| X |

| Up to MAX. A. |

| X |

|

|

| ||

| Tungsten electrodes are classified as follows by the American Welding Society (AWS): |

|

|

|

| |||||||

| Pure | EWP | green | .............EWG.........gray |

|

|

|

| ||||

| +1% Thoria | yellow |

|

|

|

|

|

|

|

| ||

| +2% Thoria | red |

|

|

|

|

|

|

|

| ||

| +2% Ceria | orange |

|

|

|

|

|

|

|

| ||

| +1.5% Lanthana | black |

|

|

|

|

|

|

|

| ||

| +0.15 to 0.40% Zirconia | ....EWZr | brown |

|

|

|

|

|

|

|

| |

Ceriated Tungsten is now widely accepted as a substitute for 2% Thoriated Tungsten in AC and DC applications.