Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

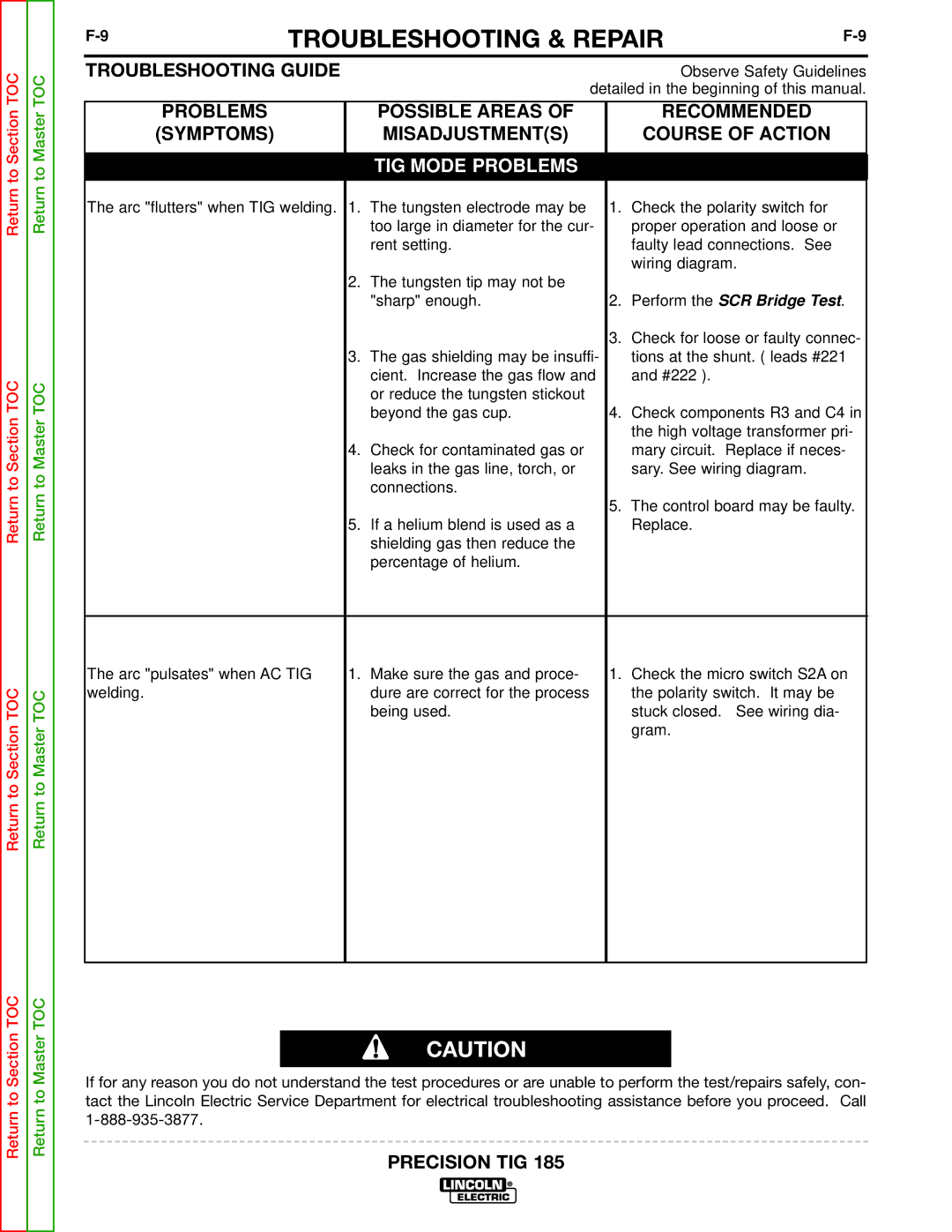

TROUBLESHOOTING & REPAIR | ||||||

TROUBLESHOOTING GUIDE |

|

| Observe Safety Guidelines | |||

|

|

| detailed in the beginning of this manual. | |||

|

|

|

|

|

|

|

| PROBLEMS |

| POSSIBLE AREAS OF |

| RECOMMENDED |

|

| (SYMPTOMS) |

| MISADJUSTMENT(S) |

| COURSE OF ACTION |

|

|

|

|

|

|

|

|

|

|

| TIG MODE PROBLEMS |

|

|

|

The arc "flutters" when TIG welding. 1. | The tungsten electrode may be | 1. | Check the polarity switch for |

| ||

|

|

| too large in diameter for the cur- |

| proper operation and loose or |

|

|

|

| rent setting. |

| faulty lead connections. See |

|

|

|

|

|

| wiring diagram. |

|

|

| 2. The tungsten tip may not be |

|

|

| |

|

|

| "sharp" enough. | 2. | Perform the SCR Bridge Test. | |

|

|

|

| 3. Check for loose or faulty connec- | ||

| 3. | The gas shielding may be insuffi- |

| tions at the shunt. ( leads #221 | ||

|

|

| cient. Increase the gas flow and |

| and #222 ). |

|

|

|

| or reduce the tungsten stickout |

|

|

|

|

|

| beyond the gas cup. | 4. | Check components R3 and C4 in | |

|

|

|

|

| the high voltage transformer pri- | |

| 4. | Check for contaminated gas or |

| mary circuit. Replace if neces- | ||

|

|

| leaks in the gas line, torch, or |

| sary. See wiring diagram. |

|

|

|

| connections. |

|

|

|

|

|

|

| 5. The control board may be faulty. | ||

| 5. | If a helium blend is used as a |

| Replace. |

| |

|

|

| shielding gas then reduce the |

|

|

|

|

|

| percentage of helium. |

|

|

|

The arc "pulsates" when AC TIG | 1. Make sure the gas and proce- | 1. Check the micro switch S2A on |

welding. | dure are correct for the process | the polarity switch. It may be |

| being used. | stuck closed. See wiring dia- |

|

| gram. |

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, con- tact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call