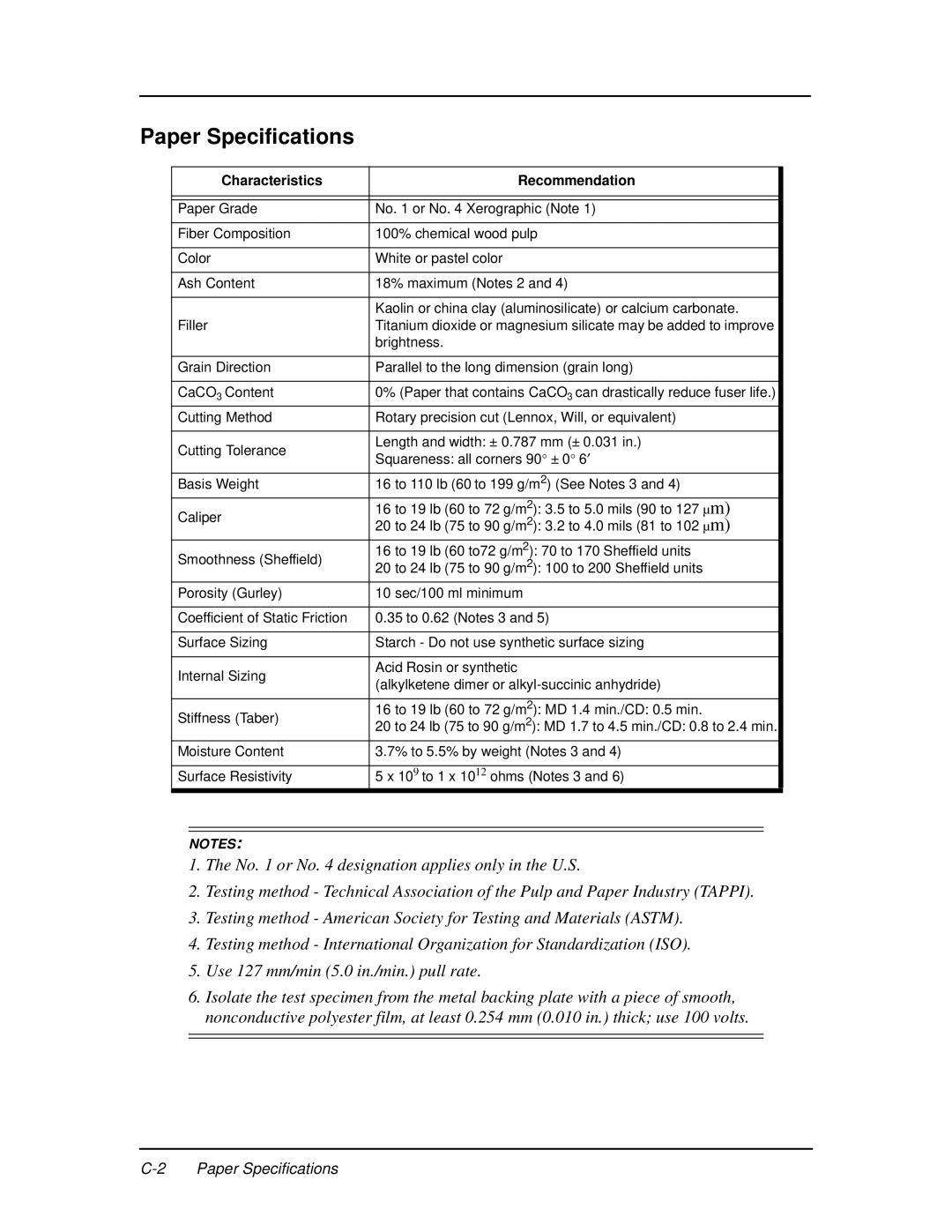

Paper Specifications

Characteristics | Recommendation |

|

|

|

|

|

|

|

Paper Grade | No. 1 or No. 4 Xerographic (Note 1) |

|

|

|

|

Fiber Composition | 100% chemical wood pulp |

|

|

|

|

Color | White or pastel color |

|

|

|

|

Ash Content | 18% maximum (Notes 2 and 4) |

|

|

|

|

| Kaolin or china clay (aluminosilicate) or calcium carbonate. |

|

Filler | Titanium dioxide or magnesium silicate may be added to improve |

|

| brightness. |

|

|

|

|

Grain Direction | Parallel to the long dimension (grain long) |

|

|

|

|

CaCO3 Content | 0% (Paper that contains CaCO3 can drastically reduce fuser life.) |

|

|

|

|

Cutting Method | Rotary precision cut (Lennox, Will, or equivalent) |

|

|

|

|

Cutting Tolerance | Length and width: ± 0.787 mm (± 0.031 in.) |

|

Squareness: all corners 90° ± 0° 6′ |

| |

|

| |

|

|

|

Basis Weight | 16 to 110 lb (60 to 199 g/m2) (See Notes 3 and 4) |

|

Caliper | 16 to 19 lb (60 to 72 g/m2): 3.5 to 5.0 mils (90 to 127 µm) |

|

20 to 24 lb (75 to 90 g/m2): 3.2 to 4.0 mils (81 to 102 µm) |

| |

|

| |

Smoothness (Sheffield) | 16 to 19 lb (60 to72 g/m2): 70 to 170 Sheffield units |

|

20 to 24 lb (75 to 90 g/m2): 100 to 200 Sheffield units |

| |

|

| |

Porosity (Gurley) | 10 sec/100 ml minimum |

|

|

|

|

Coefficient of Static Friction | 0.35 to 0.62 (Notes 3 and 5) |

|

|

|

|

Surface Sizing | Starch - Do not use synthetic surface sizing |

|

|

|

|

Internal Sizing | Acid Rosin or synthetic |

|

(alkylketene dimer or |

| |

|

| |

|

|

|

Stiffness (Taber) | 16 to 19 lb (60 to 72 g/m2): MD 1.4 min./CD: 0.5 min. |

|

20 to 24 lb (75 to 90 g/m2): MD 1.7 to 4.5 min./CD: 0.8 to 2.4 min. |

| |

|

| |

Moisture Content | 3.7% to 5.5% by weight (Notes 3 and 4) |

|

|

|

|

Surface Resistivity | 5 x 109 to 1 x 1012 ohms (Notes 3 and 6) |

|

|

|

|

NOTES:

1.The No. 1 or No. 4 designation applies only in the U.S.

2.Testing method - Technical Association of the Pulp and Paper Industry (TAPPI).

3.Testing method - American Society for Testing and Materials (ASTM).

4.Testing method - International Organization for Standardization (ISO).

5.Use 127 mm/min (5.0 in./min.) pull rate.

6.Isolate the test specimen from the metal backing plate with a piece of smooth, nonconductive polyester film, at least 0.254 mm (0.010 in.) thick; use 100 volts.