.SP6498 Belt Drive Saw 05/03 7/15/03 7:05 AM Page 54

Work Feed Devices (continued)

Push Block

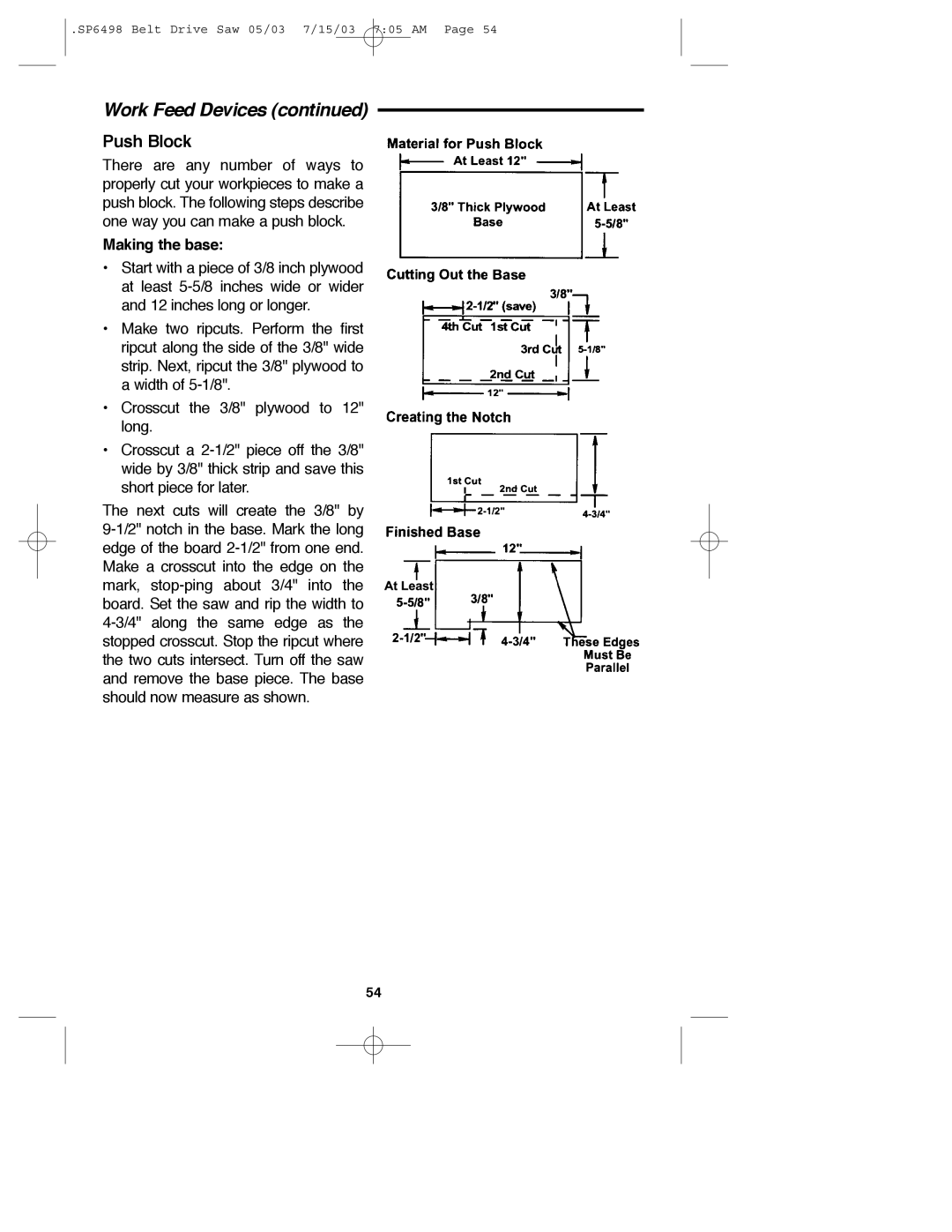

There are any number of ways to properly cut your workpieces to make a push block. The following steps describe one way you can make a push block.

Making the base:

•Start with a piece of 3/8 inch plywood at least

•Make two ripcuts. Perform the first ripcut along the side of the 3/8" wide strip. Next, ripcut the 3/8" plywood to a width of

•Crosscut the 3/8" plywood to 12" long.

•Crosscut a

The next cuts will create the 3/8" by

54