Outdoor Units

R410A Models Indoor Units

Optional Controllers

Gunma, Japan

…In Moist or Uneven Locations

…In a Room

…In an Area with High Winds

…In a Snowy Area for Heat Pump-type Systems

Check of Density Limit

Be sure to recharge the refrigerant only in liquid form

Care regarding tubing

Different tools required

New

Use R410A exclusive cylinder only

Compressor specifications are different

Single-outlet valve

Existing tubing cannot be used especially R22

Contents

AIR Purging

HOW to Process Tubing

Air Purging with a Vacuum Pump for Test Run Preparation

Test RUN

Outdoor Unit Part name

General

’ty

Model 10 hp 16 hp

4-Way Air Discharge Semi-Concealed

1-Way Air Discharge Semi-Concealed

Concealed Duct

Concealed Duct High-Static Pressure

Ceiling-Mounted

Wall-Mounted

Contents

Mark

Length ft

10 Main Tubing Size After Distribution LB, LC

Tubing Size Main Tubing Size LA

11 Outdoor Unit Tubing Connection Size a BTU/h

28.0 45.0

13 Straight Equivalent Length of Joints

Straight Equivalent Length of Joints

Additional Refrigerant Charge

16 Refrigerant Charge Amount at Shipment for outdoor unit

When using ball valve

When not using ball valve

Tube branching methods horizontal use

Model name Cooling capacity after distribution Remarks

Optional Distribution Joint Kits

Tubing size with thermal insulation

Example

232,000 BTU/h 68.0 kW

Main tubing Distribution joint tubing

Example

Main tubing

Indoor Unit

Selecting the Installation Site

Front view

Side view

Outdoor Unit

Installation Space

Leave space open above

Unit

Shield for Horizontal Exhaust Discharge

Precautions When Installing in Heavy Snow Areas

Air direction Front direction

Unit installation

Air direction

Placing the Unit Inside the Ceiling

Suspending the Indoor Unit

12, 18, 24

12, 18

Installing the Drain Piping

Start when you short the pin

Be careful since the fan will

On the indoor control board

Removing the corner cover

Panel installation locations so that the panel is

Installing the Ceiling Panel

Attached tightly to the unit. Fig

Check that the panel is attached tightly to

Wiring the Ceiling Panel

When Removing the Ceiling Panel for Servicing

Checking After Installation

Adjusting the Auto Flap

Special Remarks DC Fan Tap Change Procedure

29/64

Full-scale Installation diagram Suspension lug 25/32 1

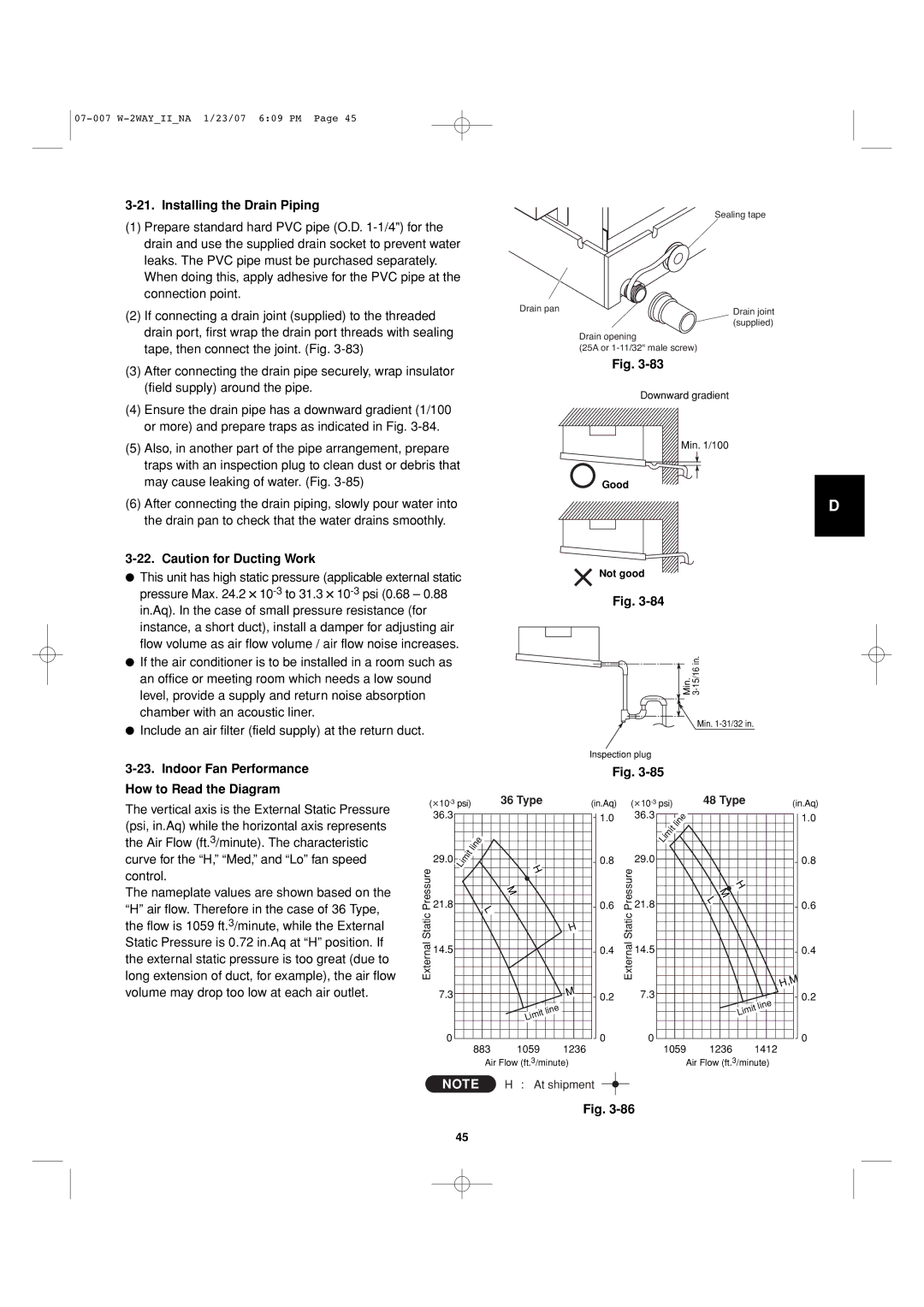

Installing the Drain Piping

Be careful since the fan will start

When you short the pin on the indoor

Control board

Bottom drain port is for use only

Wiring

Electrical Power Wiring Wiring connections

Appearance Part name

Appearance

Removing the side panel

Removing the intake grille

Adjust so that there is no gap

Installing the intake grille

Installing the side panel and intake grille

Other Check after installation

If a wireless remote controller is used

Type Length

62 and -4 show the detailed dimensions of the indoor unit

Previous page. -61 and Table

Suspension bolts referring to the dimensional data on

Tubing must be laid and connected inside the ceiling when

Unit inside the ceiling

Indoor unit

Do not use adhesive at the drain connection port on

Do not use the supplied drain hose bent at a 90 angle

Maximum permissible bend is

How to read the diagram

Be careful since the fan will start when you

Short the pin on the indoor control board

Increasing the Fan Speed

Minimum space for installation and service is shown

This air conditioner is usually installed above the ceiling

So that the indoor unit and ducts are not visible. Only

Air intake and air outlet ports are visible from below

It is important that you use extreme care

Enough to suport the weight of the unit

Supporting the indoor unit inside

Ceiling. Ensure that the ceiling is strong

Indoor Fan Performance How to Read the Diagram

Refrigerant tubing drain hose position

Service

Wall and ceiling side opening position

Weight of the unit. Before

It is important that you use

Extreme care in supporting

Inside

Duct for Fresh Air

Shaping the Tubing

Rear outlet port

When removing the fastening

How to carry out power supply wiring

Regulations before wiring

Bracket from the cover

Selecting and Making a Hole

If the Wall is Brick, Concrete or Similar

Removing the Grille to Install the Indoor Unit

Removing the grille

Attaching the grille

Shaping the Tubing Right-rear tubing

Installing the Drain Hose

Left or left-rear tubing

Unit are completed

KHX0752 / 0952 / 1252

HOW to Install the Outdoor Unit

Installing the Outdoor Unit

Transporting

Routing the Tubing

Prepare the Tubing

Connect the Tubing

Refrigerant tubing Connection method Supplied parts used?

Tightening torque for each cap

Refrigerant tube port

Work method

Cap tightening torque

Electrical Wiring

General Precautions on Wiring

Inter-outdoor unit control wiring

U, D, T Type

Wiring System Diagram

Outdoor unit Indoor unit

Shielded wire GroundGround

How to connect wiring to the terminal For stranded wiring

Connecting the Refrigerant Tubing Use of the Flaring Method

HOW to Process Tubing

Flaring Procedure with a Flare Tool

Deburring

870 Lbs · inch Over 5/128 1000 1200 kgf · cm

Tube diameter Tightening torque Tube thickness Approximate

Three tubes arranged together

Two tubes arranged together

Insulating the Refrigerant Tubing Tubing Insulation

Insulation material

Taping the Tubes

Finishing the Installation

Air Purging with a Vacuum Pump for Test Run Preparation

Bottom when you pressurize

Leak test

Use a manifold valve for air purging

45 min. or more 90 min. or more

Evacuation

Use a cylinder designed for use With R410A respectively

Charging additional refrigerant

Finishing the job

Test RUN

Items to Check Before the Test Run

Test Run Procedure

Main Outdoor Unit PCB Setting

Examples of the No. of outdoor units settings S006

Indoor unit setting S004 Rotary switch, red

3P DIP switch, blue

Address setting of main outdoor unit S007 Unit No. setting

Auto Address Setting Basic wiring diagram Example

Automatic Address Setting from the Outdoor Unit

Case

22-9

Automatic Address Setting from Outdoor Unit

Case 2 Automatic Address Setting no compressor operation

Automatic Address Setting in Heating Mode

Automatic Address Setting from Outdoor Unit

Case 3A

Automatic Address Setting in Cooling Mode

Automatic Address Setting* from the Remote Controller

Case 3B

On outdoor main unit PCB

Display during automatic address setting

If 1 indoor unit is connected to 1 remote controller

Remote Controller Test Run Settings

Checking the indoor unit addresses

07-007 W-2WAYIINA 1/23/07 609 PM

Possible cause of malfunction

Alarm contents

Alarm

Alarm messages displayed on system controller

Care and Cleaning

Appendix

Name of Parts

Should the power fail while the unit is running

Troubleshooting

Latch Air intake Safety chain Grille Bolt screws

Tips for Energy Saving

Water drain Air outlet Air intake Ceiling panel optional

Type 1-WAY

Troubleshooting

Type standard static pressure Type high static pressure

Concealed Duct High-Static Pressure Type U, D Type

Troubleshooting

Air intake grille air intake

Components and cause an electric shock hazard

Or soot

Type Wall-Mounted

Tips for Energy Saving

![]() Not good

Not good