Photometric Analyzer | Part I: Control Unit | |

|

|

|

|

|

|

|

|

|

•Which alarms - if any - are tripped

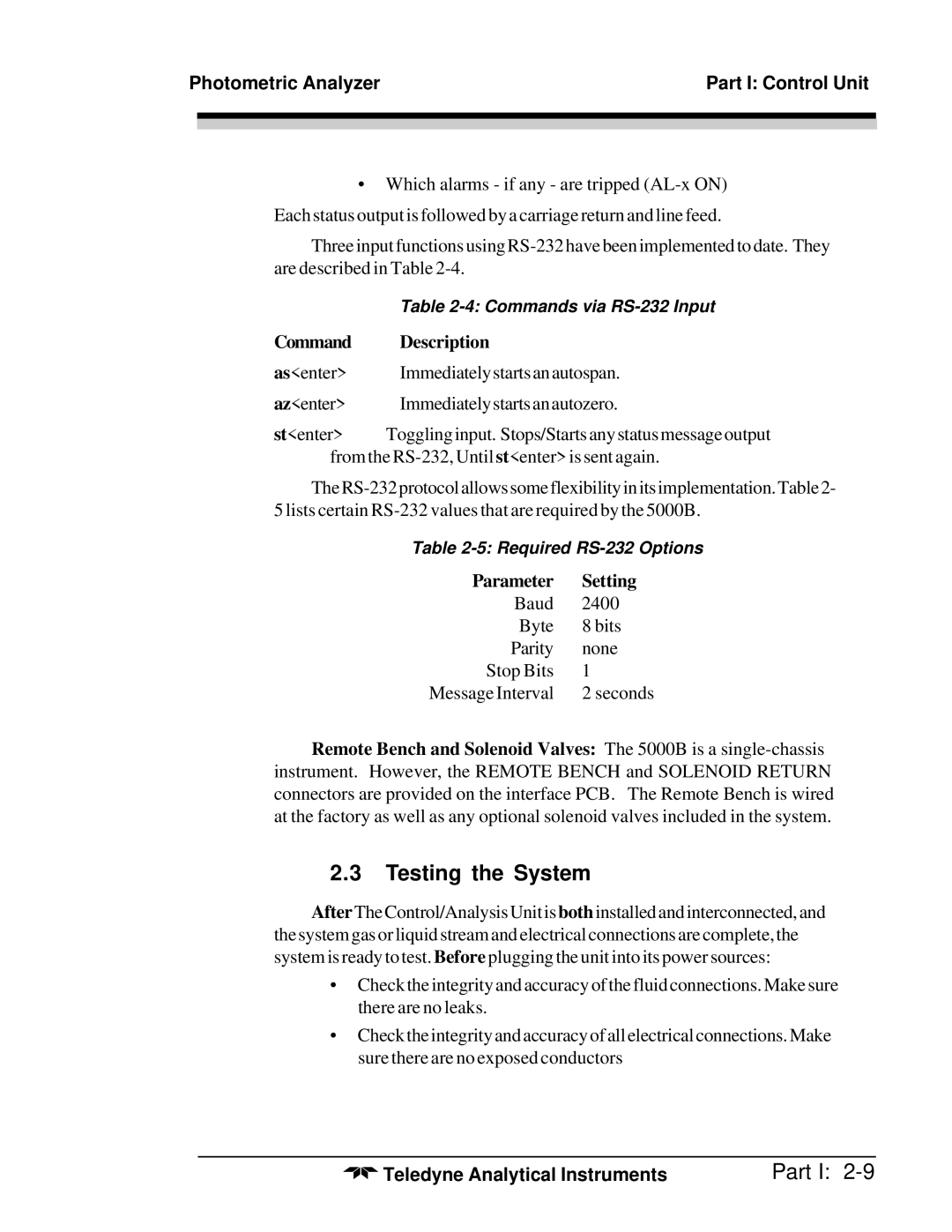

Three input functions using

| Table |

Command | Description |

as<enter> | Immediatelystartsanautospan. |

az<enter> | Immediatelystartsanautozero. |

st<enter> | Togglinginput. Stops/Startsanystatusmessageoutput |

from the

Table

Parameter | Setting |

Baud | 2400 |

Byte | 8 bits |

Parity | none |

Stop Bits | 1 |

Message Interval | 2 seconds |

Remote Bench and Solenoid Valves: The 5000B is a

2.3Testing the System

AfterTheControl/AnalysisUnitisbothinstalledandinterconnected,and the system gas or liquid stream and electrical connections are complete, the system is ready to test. Before plugging the unit into its power sources:

•Check the integrity and accuracy of the fluid connections. Make sure there are no leaks.

•Checktheintegrityandaccuracyofallelectricalconnections.Make sure there are no exposed conductors

Teledyne Analytical Instruments | Part I: |