Split Type

Contents

Original instruction

Explanation of indications

Explanation of illustrated marks

Work undertaken Protective gear worn

Indication Explanation

Confirmation of warning label on the main unit

Description

Precaution for Safety

Denger

Proceeding with the repair work

Refrigerant used by this air conditioner is the R410A

Resistance and water drainage

Explanations given to user

Relocation

Declaration of Conformity

Model names with a rating of 12 kW and below outdoor units

Safety Caution Concerned to New Refrigerant

Pipe Materials

Copper pipe Piping

Flare nut

Tools

General tools Conventional tools can be used

Specifications

Indoor Unit

Way Air Discharge Cassette Type

Single type

Twin type

Triple type

1604AT8-TR

Concealed Duct Type Single type

1104AT8-TR 1404AT8-TR

562BT-E 802BT-E Model Indoor unit

562BT-E Indoor unit

Under Ceiling Type Single type

562CT-E 802CT-E Model Indoor unit

562CT-E Indoor unit

High Wall Type Twin type

562KRT-E Indoor unit

Compact 4-Way Cassette 600 × 600 Type Twin type

1104AT8-TR

562MUT-E Indoor unit

Slim Duct Type Twin type

564SDT-E Indoor unit

High Static Duct Type Single type

Outdoor Unit

RAV-SP

Operation Characteristic Curve

Operation characteristic curve, 50Hz Super Digital Inverter

Operation characteristic curve, 60Hz Super Digital Inverter

RAV-SP1104AT7 Z ZG RAV-SP1404AT7 Z ZG RAV-SP1604AT7 Z ZG

Capacity variation ratio according to temperature

Cooling Heating

Construction Views External Views

Name

RBC-TWP30E2, RBC-TWP50E2 Simultaneous Twin

Model RBC

RBC-TRP100E Simultaneous Triple Gas side

Liquid side

Gas side socket

Liquid side socket

RAV-SP160 type

RAV-SP110 type

RAV-SP140 type

Wiring Diagram

Specifications of Electrical Parts

Parts name Type Specifications

Safety During Installation/Servicing

Refrigerant Piping Installation

Refrigerant R410A

Piping Materials and Joints Used

Processing of Piping Materials

Flare Processing Procedures and Precautions

Joints

Flare and flare nut dimensions for R22

3 Dimensions related to flare processing for R410A / R22

Flare and flare nut dimensions for R410A

Wrenches available on the market

Flare Connecting Procedures and Precautions

Nm kgfm

Recharging of Refrigerant

Required Tools

Low temperature brazing filler

Flux Reason why flux is necessary

Brazing of Pipes

Materials for Brazing Silver brazing filler

Characteristics required for flux

Types of flux

Piping materials for brazing and used brazing filler/flux

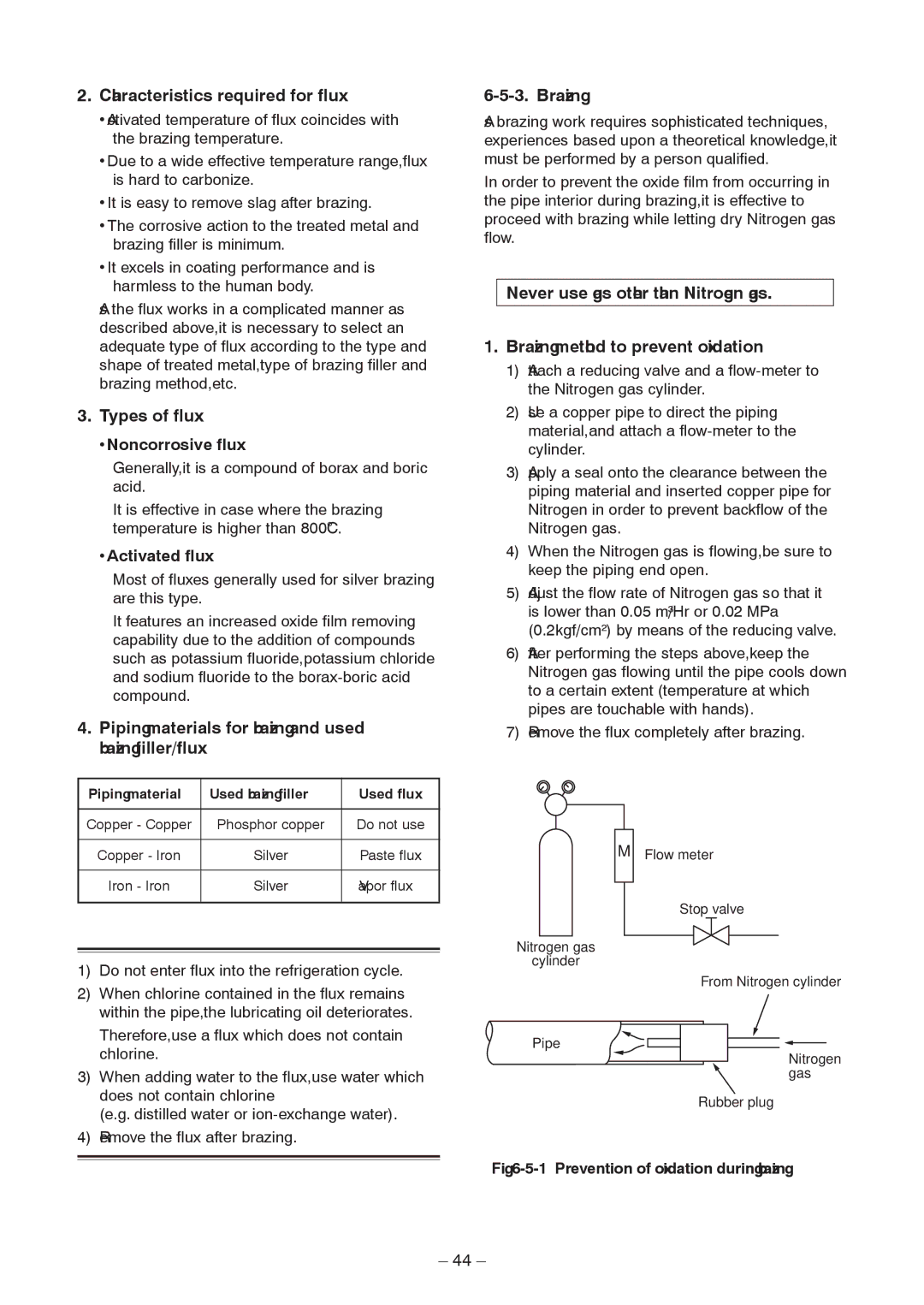

Brazing

Instructions for Re-use Piping of R22 or R407C

Basic Conditions Needed to Reuse the Existing Pipe

Restricted Items to Use the Existing Pipes

Branching Pipe for Simultaneous Operation System

Final Installation Checks

Existing pipe SW Switch

Recovery Method of Refrigerant

Procedure

Handling of Existing Pipe

Reference outside diameter Wall thickness

Print Circuit Board, MCC-1596 Compressor Ipdu

Circuit Configuration and Control Specifications

Outdoor Unit Control

Print Circuit Board, MCC-1597 Fan Motor Ipdu

CN700 Blue CN500 Red

CN504 Blue

F500

Print Circuit Board, MCC-1599 Interface CDB

CN23 Red

CN05 Red CN10 Red CN16 Red

F03

Discharge temperature release control

Outline of Main Controls PMV Pulse Motor Valve control

Heating fan control

Outdoor fan control

Cooling fan control

Current release control

Coil heating control

Short intermittent operation preventive control

Temperature range SP110

Current release value shift control

Over-current protective control

High-pressure release control

High-pressure switch/Compressor case thermostat control

Defrost control

Start of heating operation

Normal To Abnormal To

Troubleshooting

Summary of Troubleshooting

Before troubleshooting

Troubleshooting procedure

Wireless remote controller type

Trouble Confirmation of lamp display

Lamp indication Check code Cause of trouble occurrence

Troubleshooting

Outline of judgment

Ready

Others Other than Check Code

Lamp indication Check code

Contents

Check Code List Outdoor

Reset

Timer Ready Flash F01

Error mode detected by indoor unit

Cause of operation Status

Error mode detected by outdoor unit

Series

Operation of diagnostic function

Power supply error of remote controller, Indoor

Display selection

Diagnostic Procedure for Each Check Code Outdoor Unit

LED display on outdoor P.C. board Dip switch setup

F06

Display Display 2 Heat exchanger temp. sensor TE error

F07 Display Display 2 Heat exchanger temp. sensor TL error

F12 Display Display 2 Suction temp. sensor TS error

F13 Display Display 2 Heat sink temp. sensor TH error

H01 Display Compressor break down

H02 Display Compressor lock

L10 Display

YES

Display Display 2 Communication error between MCU

Display 1 Display 2 Unset model type → Refer to L10 column

Display High pressure SW system error

P04

Normally operate?

P15 Display Gas leak detection

P07 Display Heat sink overheat error

P19 Display Way valve inverse error

Heating operation

Position detection circuit error

Single operation check for outdoor fan

P26

Display 2 Short-circuit of compressor drive element

Temperature sensor

TA, TC, TCJ, TE, TS, to sensors Representative value

TD,TL sensors Representative value

TA, TC, TCJ, TE, TS, to sensors

Parts name Checking procedure

Table Inspection of outdoor unit main parts

Resistance value

Position

Setup AT Local Site and Others

Calling of Error History

Contents

Group Control Operation

Indoor unit power-ON sequence

By feed unit Automatic address judgment

Initial communication

Usual regular Communication

Max. frequency of compressor

Function Set position Control contents

Defrost control

Display part

Specifications Operation contents

Operation part

Display selection list

Switch Function / Contents Refer

Others Selection of LED display SW800, SW803 operation

Error display

¥¥ll¡

Setup

Opening

Pulse

Display

Specific operation

Specific operation for maintenance check SW801, SW804

SW804 Operation when pushdown button switch SW801 is pushed

For check RY703, CN703 check

Address Setup

Address Setup Procedure

Terminology

Address Setup & Group Control

System Configuration

Example

Automatic Address Example from Unset Address No miswiring

Only turning on source power supply Automatic completion

Standard One outdoor unit Single Twin Triple SP160 only

Remote Controller Wiring

Wiring diagram

Single system Simultaneous twin system

Simultaneous triple system SP160 only

Address Setup Manual setting from remote controller

Procedure

Confirmation of Indoor Unit No. Position

To know the position of indoor unit body by address

Button

Maintenance/Check list

Replacement of the Service P.C. Board 4316V417 MCC-1599

Setting the jumper wires and DIP switches

Model switching J800 to J803

Part name Function Setting

HOW to Exchange Compressor

Exchanging Procedure of Compressor Outline

Exchange of Compressor

100

Contents

Work undertaken Protective gear worn

102

Definition of Protective Gear

103

To Disconnect the Appliance from the Main Power Supply

104

Explanations given to user

Relocation

Accessory Parts

Required Tools/Equipment and Precautions for Use

Tools/equipment Use How to use tools/equipment

105

Airtight test

Before installation

106

107

Installation Location

Necessary Space for Installation Unit mm

Installation of Outdoor Unit

Knockout procedure

108

For Reference

Optional Installation Parts Locally procured

Tightening of Connecting Part

109

Refrigerant Piping Connection

Air Purge

110

Refrigerant Pipe Length

How to open the valve

Wiring between Indoor Unit and Outdoor Unit

111

Replenishing refrigerant

Super Digital Inverter How to wire Wiring diagram

112

Single system, Twin system, Triple system

Single system

Handling Existing Pipe

Recovering Refrigerant

113

Verifying current abnormal status

Super Digital Inverter Cause Display mode

114

115

116

7DB

117

Declaration of Conformity

Detachments

118

RAV-SP1104AT8 7, RAV-SP1404AT8 7, RAV-SP1604AT8 7 series

Detachment

119

120

Part name Procedure Remarks

121

Part name Procedure

122

123

124

125

Compressor 1. Detachment

Requirement

126

Compressor 1. Removal of defective compressor

No. Part name Procedure Remarks

127

128

Mounting of compressor

Vacuuming

Refrigerant charge

129

Exploded Views and Parts List

130

131

1104AT7ZG

132

Inverter Assembly

721

133

134

135

1404AT7ZG

Inverter Unit

136

137

138

139

1604AT7ZG

140

141

Check of Concentration Limit

Toshiba Carrier Corporation

![]()

![]()

![]() Nitrogen gas

Nitrogen gas