Troubleshooting (continued)

Stopping when printing

The printer may stop with no error messages If some failure with the connection to the host computer occur or the not proper ink ribbon is set.

In this case, open and close the printer door at once,

and then press “reset” and press “enter” to intialize the printer.

Mending broken ink ribbon and

retransfer film

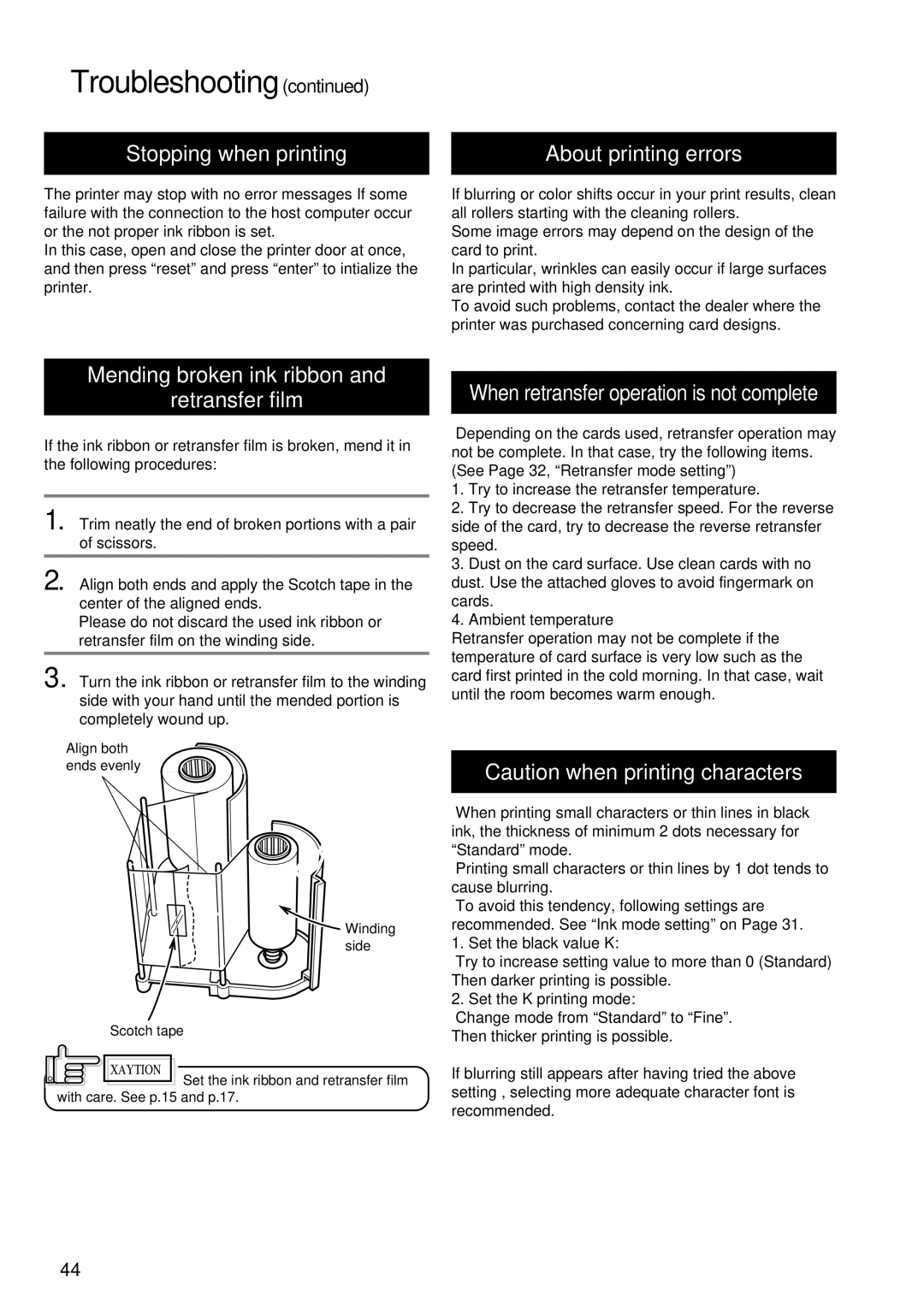

If the ink ribbon or retransfer film is broken, mend it in the following procedures:

1. Trim neatly the end of broken portions with a pair of scissors.

2. Align both ends and apply the Scotch tape in the center of the aligned ends.

Please do not discard the used ink ribbon or retransfer film on the winding side.

3. Turn the ink ribbon or retransfer film to the winding side with your hand until the mended portion is completely wound up.

Align both ends evenly

![]() Winding

Winding ![]() side

side

Scotch tape

CAUTION

![]() Set the ink ribbon and retransfer film with care. See p.15 and p.17.

Set the ink ribbon and retransfer film with care. See p.15 and p.17.

About printing errors

If blurring or color shifts occur in your print results, clean all rollers starting with the cleaning rollers.

Some image errors may depend on the design of the card to print.

In particular, wrinkles can easily occur if large surfaces are printed with high density ink.

To avoid such problems, contact the dealer where the printer was purchased concerning card designs.

When retransfer operation is not complete

Depending on the cards used, retransfer operation may not be complete. In that case, try the following items. (See Page 32, “Retransfer mode setting”)

1.Try to increase the retransfer temperature.

2.Try to decrease the retransfer speed. For the reverse side of the card, try to decrease the reverse retransfer speed.

3.Dust on the card surface. Use clean cards with no dust. Use the attached gloves to avoid fingermark on cards.

4.Ambient temperature

Retransfer operation may not be complete if the temperature of card surface is very low such as the card first printed in the cold morning. In that case, wait until the room becomes warm enough.

Caution when printing characters

When printing small characters or thin lines in black ink, the thickness of minimum 2 dots necessary for “Standard” mode.

Printing small characters or thin lines by 1 dot tends to cause blurring.

To avoid this tendency, following settings are recommended. See “Ink mode setting” on Page 31.

1. Set the black value K:

Try to increase setting value to more than 0 (Standard) Then darker printing is possible.

2. Set the K printing mode:

Change mode from “Standard” to “Fine”. Then thicker printing is possible.

If blurring still appears after having tried the above setting , selecting more adequate character font is recommended.

44