Hazardous Area Oxymitter DR

Instruction Manual

1

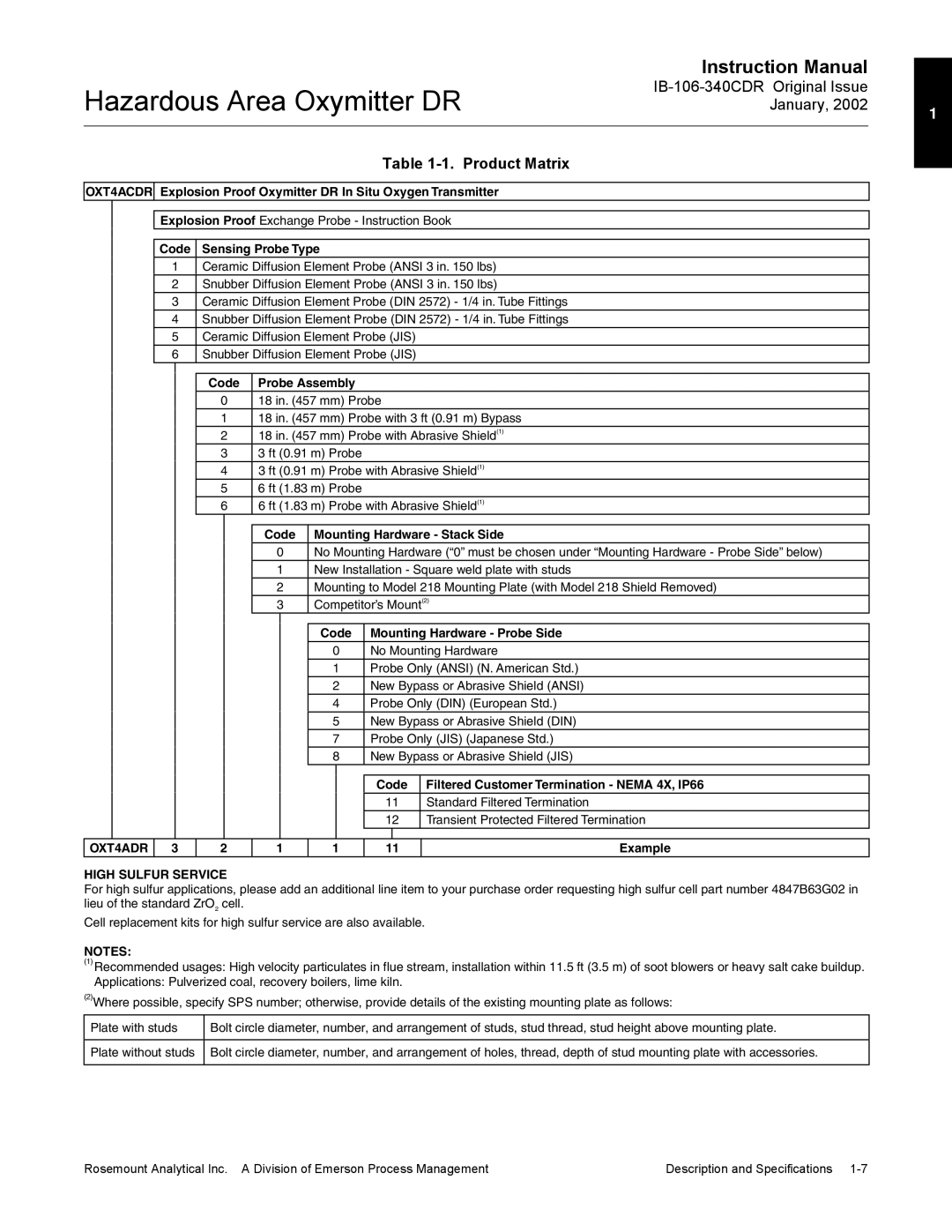

Table 1-1. Product Matrix

OXT4ACDR Explosion Proof Oxymitter DR In Situ Oxygen Transmitter

Explosion Proof Exchange Probe - Instruction Book

Code Sensing Probe Type

1Ceramic Diffusion Element Probe (ANSI 3 in. 150 lbs)

2Snubber Diffusion Element Probe (ANSI 3 in. 150 lbs)

3Ceramic Diffusion Element Probe (DIN 2572) - 1/4 in. Tube Fittings

4Snubber Diffusion Element Probe (DIN 2572) - 1/4 in. Tube Fittings

5Ceramic Diffusion Element Probe (JIS)

6Snubber Diffusion Element Probe (JIS)

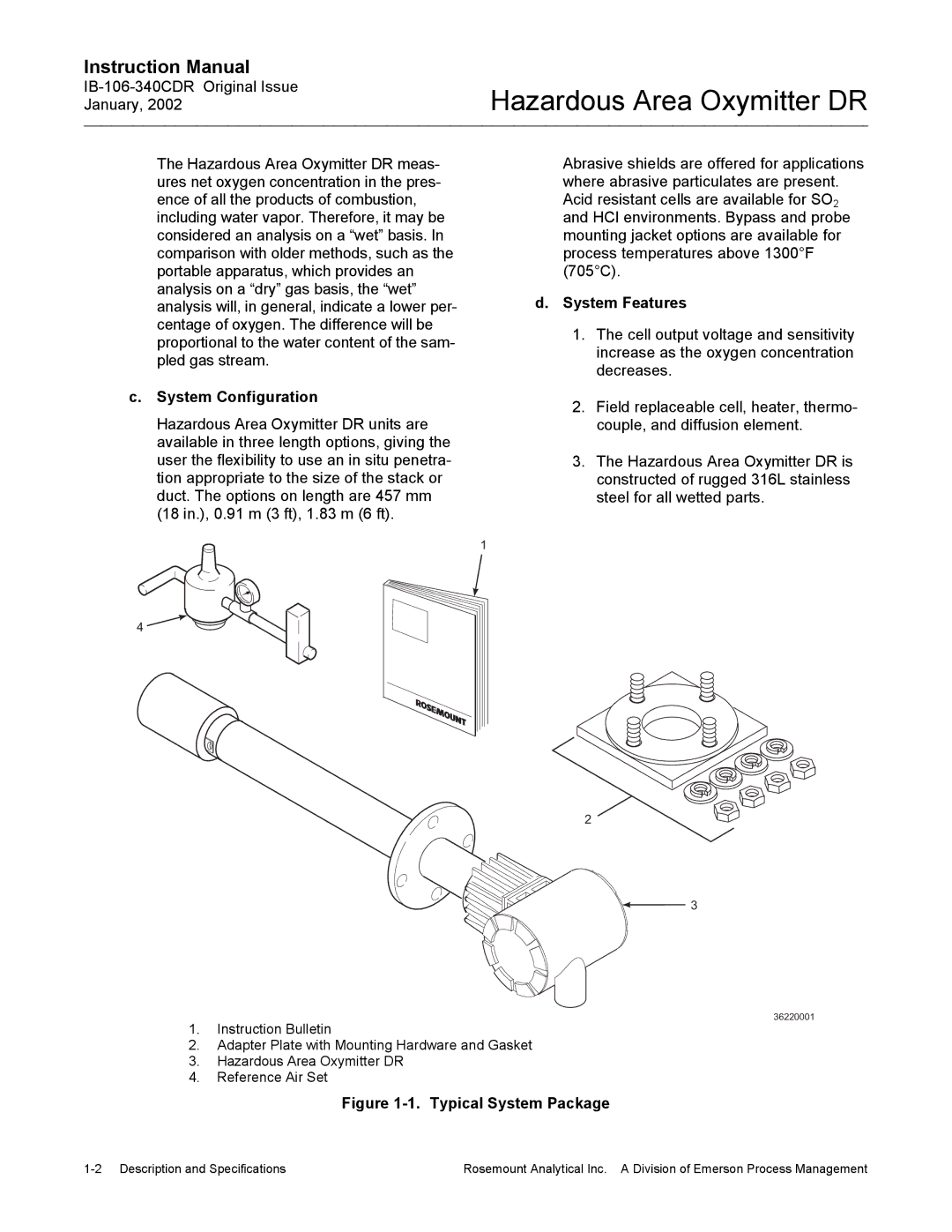

Code Probe Assembly

018 in. (457 mm) Probe

118 in. (457 mm) Probe with 3 ft (0.91 m) Bypass

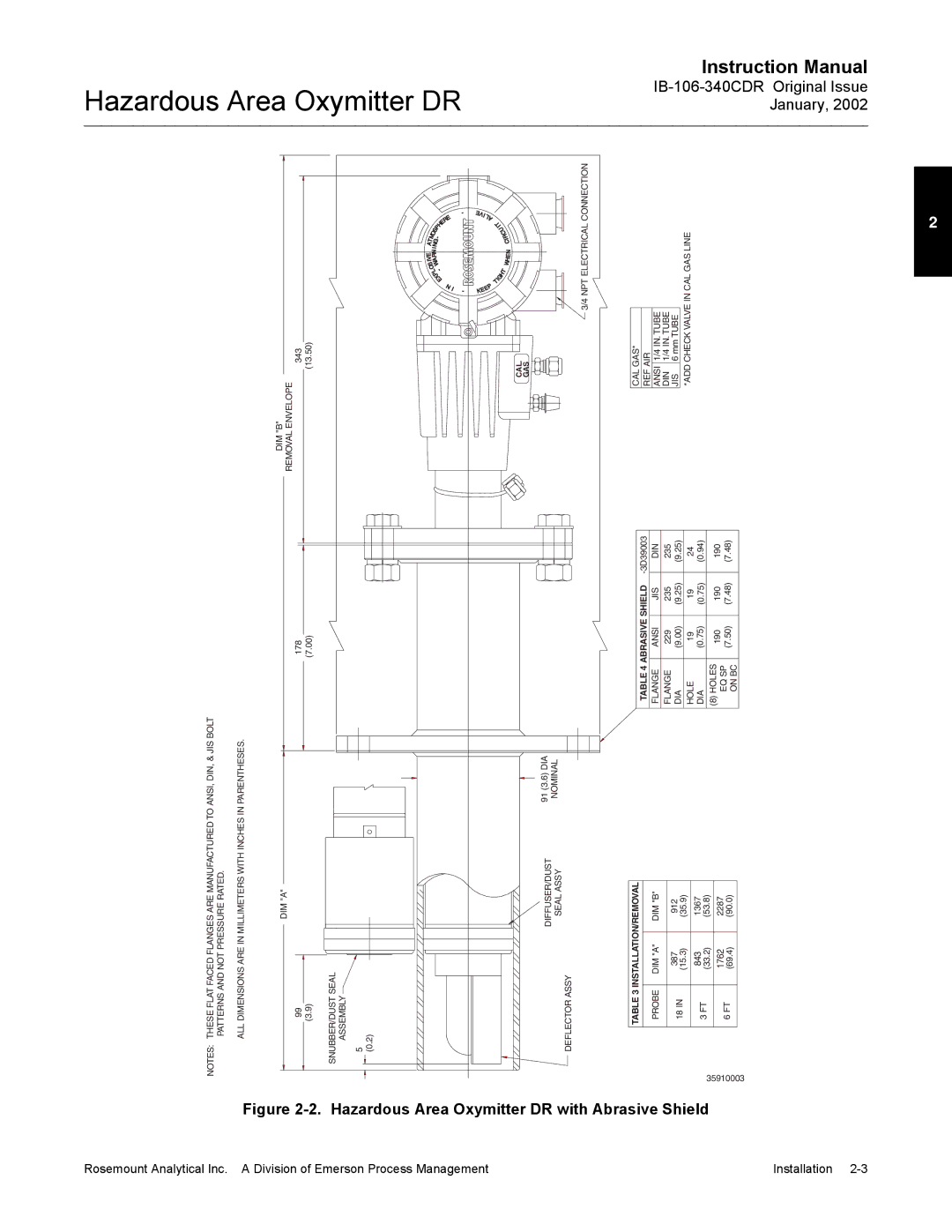

218 in. (457 mm) Probe with Abrasive Shield(1)

33 ft (0.91 m) Probe

43 ft (0.91 m) Probe with Abrasive Shield(1)

56 ft (1.83 m) Probe

66 ft (1.83 m) Probe with Abrasive Shield(1)

Code Mounting Hardware - Stack Side

0No Mounting Hardware (“0” must be chosen under “Mounting Hardware - Probe Side” below)

1New Installation - Square weld plate with studs

2Mounting to Model 218 Mounting Plate (with Model 218 Shield Removed)

3Competitor’s Mount(2)

Code Mounting Hardware - Probe Side

0No Mounting Hardware

1Probe Only (ANSI) (N. American Std.)

2New Bypass or Abrasive Shield (ANSI)

4Probe Only (DIN) (European Std.)

5New Bypass or Abrasive Shield (DIN)

7Probe Only (JIS) (Japanese Std.)

8New Bypass or Abrasive Shield (JIS)

Code Filtered Customer Termination - NEMA 4X, IP66

11Standard Filtered Termination

12Transient Protected Filtered Termination

OXT4ADR

3

2

1

1

11

Example

HIGH SULFUR SERVICE

For high sulfur applications, please add an additional line item to your purchase order requesting high sulfur cell part number 4847B63G02 in lieu of the standard ZrO2 cell.

Cell replacement kits for high sulfur service are also available.

NOTES:

(1)Recommended usages: High velocity particulates in flue stream, installation within 11.5 ft (3.5 m) of soot blowers or heavy salt cake buildup.

Applications: Pulverized coal, recovery boilers, lime kiln.

(2)Where possible, specify SPS number; otherwise, provide details of the existing mounting plate as follows:

Plate with studs | Bolt circle diameter, number, and arrangement of studs, stud thread, stud height above mounting plate. |

|

|

Plate without studs | Bolt circle diameter, number, and arrangement of holes, thread, depth of stud mounting plate with accessories. |

|

|

Rosemount Analytical Inc. A Division of Emerson Process Management | Description and Specifications |