When removing the post, the friction pin (C) and compression ball (D) may come loose. To reinstall parts:

1.Remove adjustment set screw (E) Fig. 33B.

2.Install new guide post (F), making sure channel is oriented towards guide post lock knob (G) and tighten lock knob.

3.Place friction pin through hole in casting behind set screw (E) and then place compressing ball in same hole.

4.Thread adjustment set screw in place until tight.

5.Loosen guide post lock knob (G), the turn adjustment set screw (E) until desired force to move guide is attained.

Always tighten guide post lock knob prior to using the band saw

F

G

E

Fig. 33B

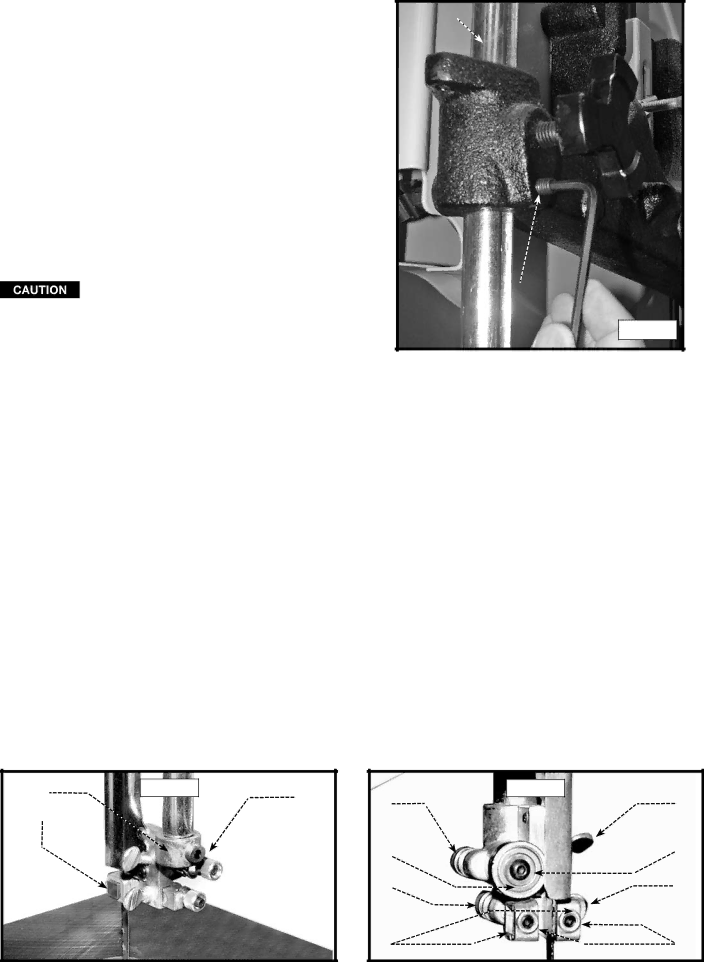

adjusting THE upper blade guides and blade support bearing

Adjust the upper blade guides and blade support bearings ONLY after the blade has the correct tension and is tracking properly. To adjust:

Disconnect the machine from the power source!

Disconnect the machine from the power source!

1.Confirm that the bottom blade guides and support bearings are not touching the blade.

2.Observe the upper blade guide assembly. The blade guides (A) Fig. 34 should be parallel to the blade. To adjust, loosen the screw (B) and rotate the complete guide assembly (C). When the blade guides are parallel with the blade, tighten the screw (B).

3.Adjust the guides (A) Fig. 35 so that the front edge of the guides are just behind the "gullets" of the saw teeth. You can move the complete guide block bracket in or out by loosening the thumb screw (C) and turning the knurled knob (D) Fig.

35.When the guides (A) are set properly, tighten the thumb screw (C).

4.Two set screws (B) Fig. 35 hold the upper blade guides (A) in place. Loosen the set screws (B) to move the guides (A). Place them as close as possible to the side of the blade. (Do not pinch the blade). Tighten the screws (B).

5.The upper blade support bearing (E) Fig. 35 prevents damage to the set in the saw teeth by keeping the blade held forward. Set the support bearing (E) 1/64" behind the blade. Loosen the thumb screw (F) and turn the knurled knob (G) to move the support bearing (E) in or out.

6.Adjust the blade support bearing (E) so that the back edge of the blade overlaps the outside diameter of the ball bearing by about 1/16". The bearing (E) is set on an eccentric. To change the position, remove the screw (H) and bearing (E) Fig.

35.Loosen the thumb screw (F), and back out the knurled knob from the set screw. Remove the hex shaft from the hole, and rotate it to move the eccentric for the bearing.

7.When the blade guide wears so that it cannot be adjusted close to the blade, loosen the screw (B) Fig. 35 and reverse the blade guides (A) Fig. 35.

C A

Fig. 34

B |

| Fig. 35 | |

G | F | ||

| |||

| E | H | |

|

| ||

| D | C | |

| A | B | |

| 19 - English |

|