Setup Mode Details

|

|

|

|

|

|

|

|

|

| e |

|

|

|

|

|

|

|

|

| g | |

|

|

|

|

|

|

|

| n |

| |

|

|

|

|

|

|

| a |

|

| |

|

|

|

|

|

| R |

|

|

| |

|

|

|

|

| l |

|

|

|

| |

|

|

|

| o |

|

|

|

|

| |

|

|

| r |

|

|

|

|

|

| |

|

| t |

|

|

|

|

|

|

| |

| n |

|

|

|

|

|

|

|

| |

o |

|

|

|

|

|

|

|

|

| |

C |

|

|

|

|

|

|

|

|

|

|

BPressure Too High

BPressure Too Low

|

|

|

|

|

|

|

|

|

|

|

| e |

|

|

|

|

|

|

|

|

|

|

| g | |

|

|

|

|

|

|

|

|

| n |

| ||

|

|

|

|

|

|

|

| a |

|

|

| |

|

|

|

|

|

| lR |

|

|

|

| ||

|

|

|

|

| o |

|

|

|

|

|

| |

|

|

|

| r |

|

|

|

|

| l) | ||

|

|

| t |

|

|

|

|

|

| |||

| n |

|

|

|

|

|

| l |

| |||

o |

|

|

|

|

|

|

| a |

|

| ||

C |

|

|

|

|

|

| m |

|

|

| ||

|

|

|

|

| os |

|

|

|

|

| ||

|

|

| o |

|

|

|

|

|

|

| ||

|

| t |

|

|

|

|

|

|

|

|

| |

| ( |

|

|

|

|

|

|

|

|

|

| |

B Pressure

Too High

BPressure Too Low

A Pressure B Pressure

A Pressure B Pressure

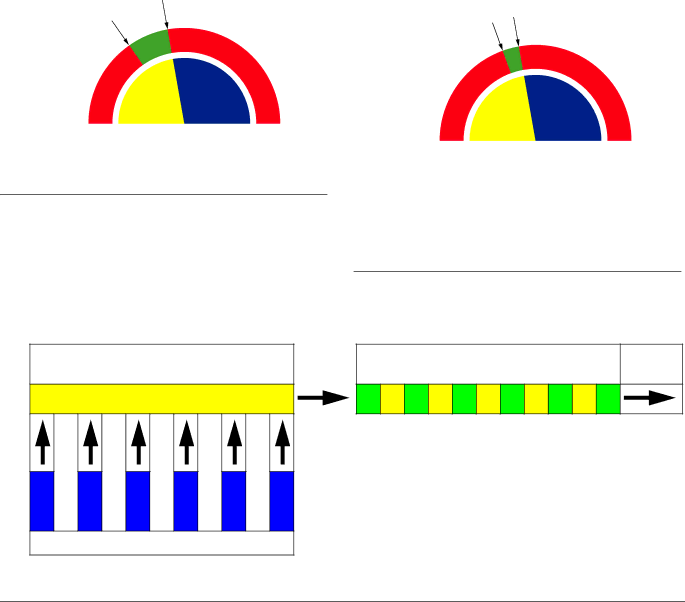

FIG. 50. A/B Control Range with Properly Sized Restrictor

NOTE: If the restrictor is too small, it may be necessary to supply more differential pressure than is available in your system.

FIG. 51. A/B Control Range with Too Large a Restrictor

Component A (continuous flow)

Proportioned Material

To Static

Mixer

Component B (pulsed injection)

FIG. 52. Schematic Diagram of Dynamic Dosing Operation

Table 2: Dynamic Dosing Troubleshooting Guide

(for complete system troubleshooting, see Table 3 beginning on page 52)

Error Message | Solution | |

|

|

|

|

| |

Ratio Low Error (R1) | • Increase A pressure or decrease B pressure. |

|

| • Use a smaller restrictor. | |

|

| |

Ratio High Error (R4) | • Increase B pressure. | |

| • Clean restrictor or use a larger size. | |

| • Verify B valve is opening properly. | |

|

|

|

3A0868G | 49 |