Setting Equipment

![]() WARNING

WARNING

Do not install the furnace on its front or its back. Do not connect the return air ducts to the back of the fur- nace. Doing so will adversely affect the operation of the safety control devices, which could result in per- sonal injury or death.

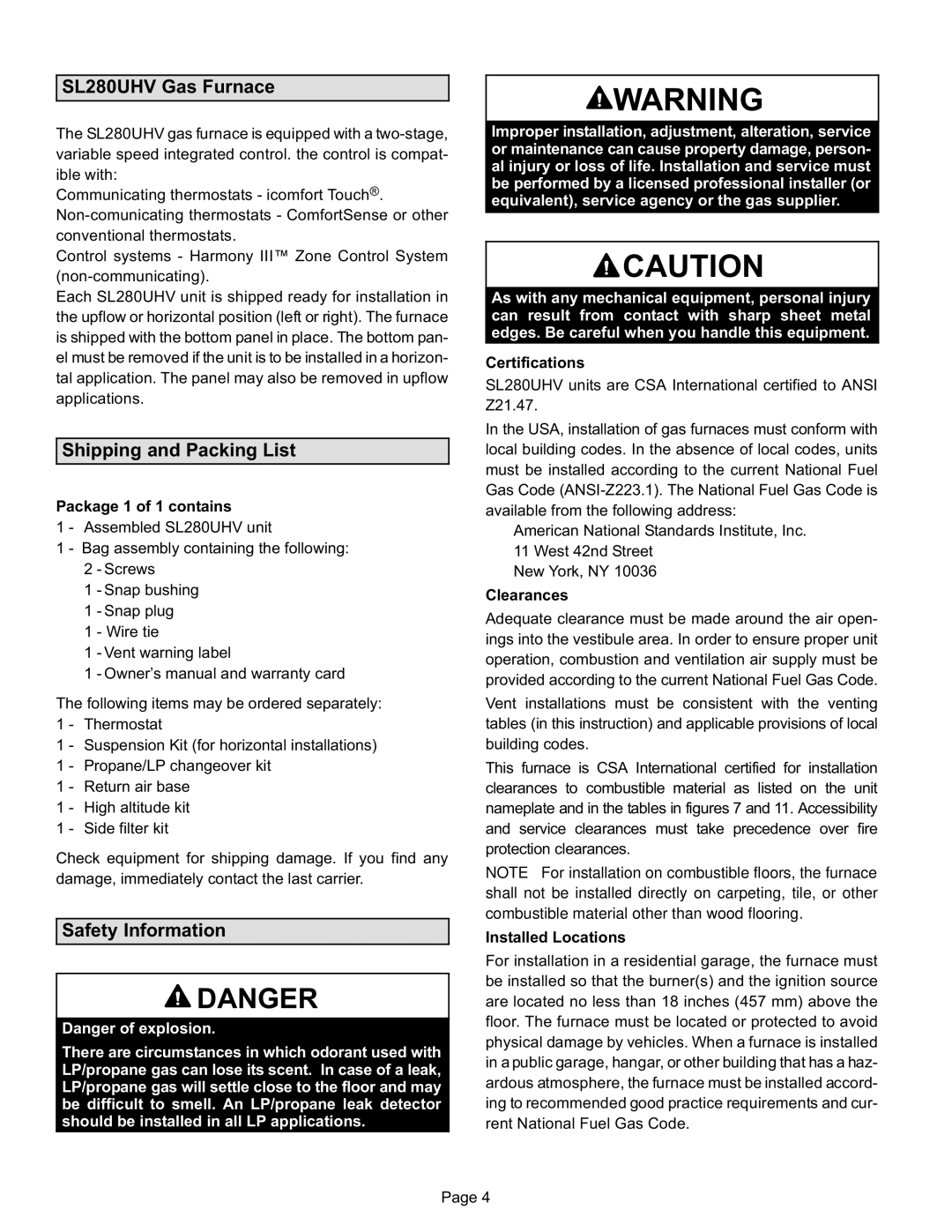

The SL280UHV gas furnace can be installed as shipped in either the upflow position or the horizontal position. Select a location that allows for the required clearances that are listed on the unit nameplate. Also consider gas supply connections, electrical supply, vent connection, and installation and service clearances [24 inches (610

mm)at unit front]. The unit must be level.

NOTE − Units with 1/2 hp blower motors are equipped with three flexible legs and one rigid leg. See figure 6. The rigid leg is equipped with a shipping bolt and a flat white plastic washer (rather than the rubber mounting grommet used with a flexible mounting leg). The bolt and washer must be removed before the furnace is placed into opera- tion. After the bolt and washer have been removed, the rig- id leg will not touch the blower housing.

SL280UHV07036A and

SL280UHV09036B WITH 1/2 HP

BLOWER MOTOR

RIGID LEG

remove shipping bolt and washer

FIGURE 6

Upflow Applications

Allow for clearances to combustible materials as indicated on the unit nameplate. Minimum clearances for closet or al- cove installations are shown in figure 7.

Upflow Application Installation Clearances

| Top |

| |

Left Side |

| Right Side | |

| AIR FLOW |

| |

| Bottom |

| |

Type of Vent | Type C | Type B1 | |

Connector | |||

|

| ||

Top | 1 in. (25 mm) | 1 in. (25 mm) |

*Front | 2−1/4 in. (57 mm)** | 2−1/4 in. (57 mm) |

|

|

|

Back | 0 | 0 |

|

|

|

Sides | 0† | 0 |

|

|

|

Vent | 6 in. (152 mm) | 1 in. (25 mm) |

|

|

|

Floor | 0‡ | 0‡ |

*Front clearance in alcove installation must be 24 in. (610 mm). Maintain a minimum of 24 in. (610 mm) for front service access. ** 3−1/4 in. if single wall vent pipe is used.

‡For installation on a combustible floor, do not install the furnace directly on carpeting, tile or other combustible materials other than wood flooring.

†Left side requires 3 inches if a single wall vent is used on 14−1/2 inch cabinets, or 2 in. if a single wall vent is used on 17−1/2 in. cabi- nets.

FIGURE 7

Page 9