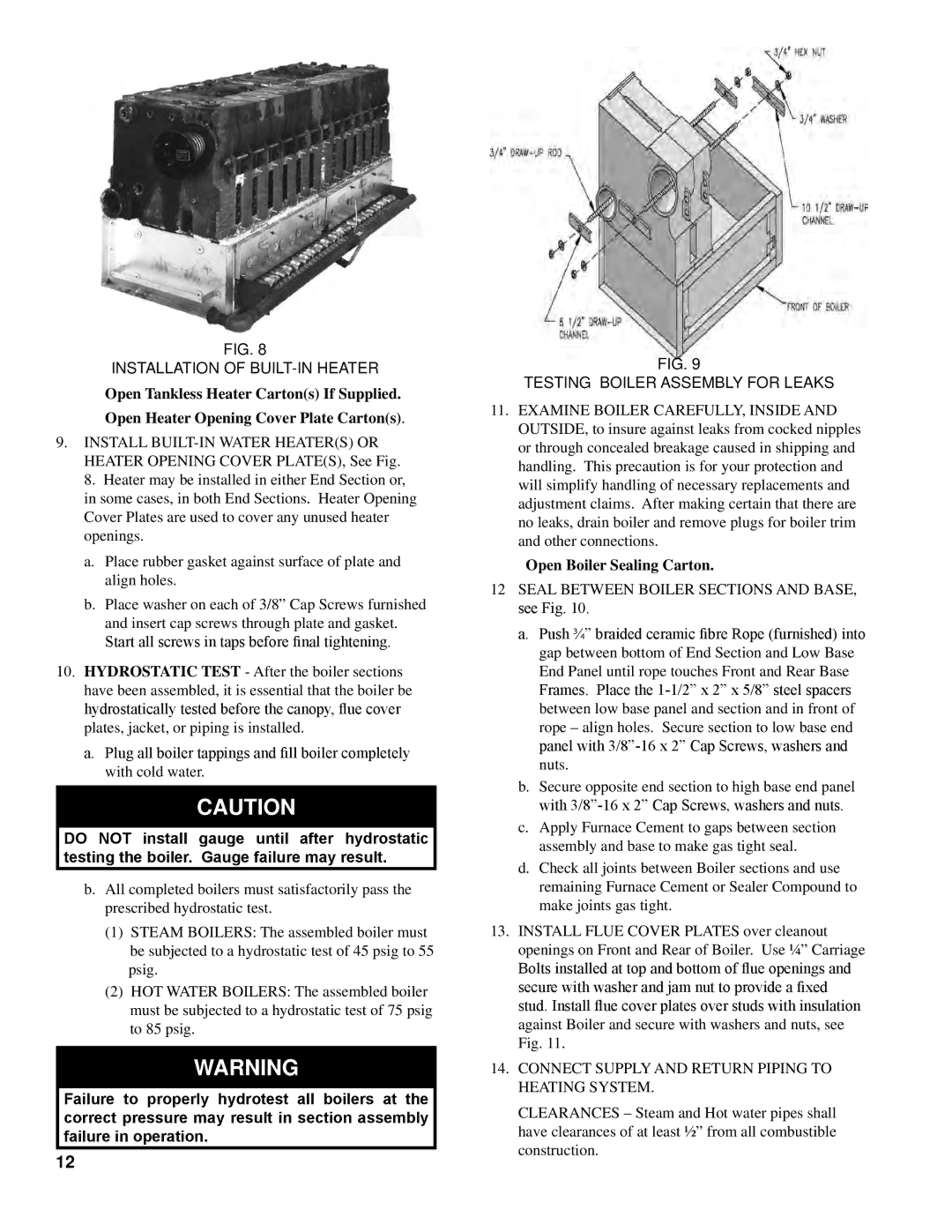

Fig. 8

INSTALLATION OF BUILT-IN HEATER

Open Tankless Heater Carton(s) If Supplied. Open Heater Opening Cover Plate Carton(s).

9.INSTALL

8. Heater may be installed in either End Section or, in some cases, in both End Sections. Heater Opening Cover Plates are used to cover any unused heater openings.

a.Place rubber gasket against surface of plate and align holes.

b.Place washer on each of 3/8” Cap Screws furnished and insert cap screws through plate and gasket.

Start all screws in taps before final tightening.

10.HYDROSTATIC TEST - After the boiler sections have been assembled, it is essential that the boiler be hydrostatically tested before the canopy, flue cover plates, jacket, or piping is installed.

a.Plug all boiler tappings and fill boiler completely with cold water.

CAUTION

DO NOT install gauge until after hydrostatic testing the boiler. Gauge failure may result.

b.All completed boilers must satisfactorily pass the prescribed hydrostatic test.

(1)STEAM BOILERS: The assembled boiler must be subjected to a hydrostatic test of 45 psig to 55 psig.

(2)HOT WATER BOILERS: The assembled boiler must be subjected to a hydrostatic test of 75 psig to 85 psig.

WARNING

Failure to properly hydrotest all boilers at the correct pressure may result in section assembly failure in operation.

12

Fig. 9

TESTING BOILER ASSEMBLY FOR LEAKS

11.EXAMINE BOILER CAREFULLY, INSIDE AND OUTSIDE, to insure against leaks from cocked nipples or through concealed breakage caused in shipping and handling. This precaution is for your protection and will simplify handling of necessary replacements and adjustment claims. After making certain that there are no leaks, drain boiler and remove plugs for boiler trim and other connections.

Open Boiler Sealing Carton.

12SEAL BETWEEN BOILER SECTIONS AND BASE, see Fig. 10.

a.Push ¾” braided ceramic fibre Rope (furnished) into gap between bottom of End Section and Low Base End Panel until rope touches Front and Rear Base

Frames. Place the

b.Secure opposite end section to high base end panel with

c.Apply Furnace Cement to gaps between section assembly and base to make gas tight seal.

d.Check all joints between Boiler sections and use remaining Furnace Cement or Sealer Compound to make joints gas tight.

13.INSTALL FLUE COVER PLATES over cleanout openings on Front and Rear of Boiler. Use ¼” Carriage

Bolts installed at top and bottom of flue openings and secure with washer and jam nut to provide a fixed stud. Install flue cover plates over studs with insulation against Boiler and secure with washers and nuts, see Fig. 11.

14.CONNECT SUPPLY AND RETURN PIPING TO HEATING SYSTEM.

CLEARANCES – Steam and Hot water pipes shall have clearances of at least ½” from all combustible construction.