5. MAIN BURNER FLAMES –

Main Burner Flames should be checked at initial

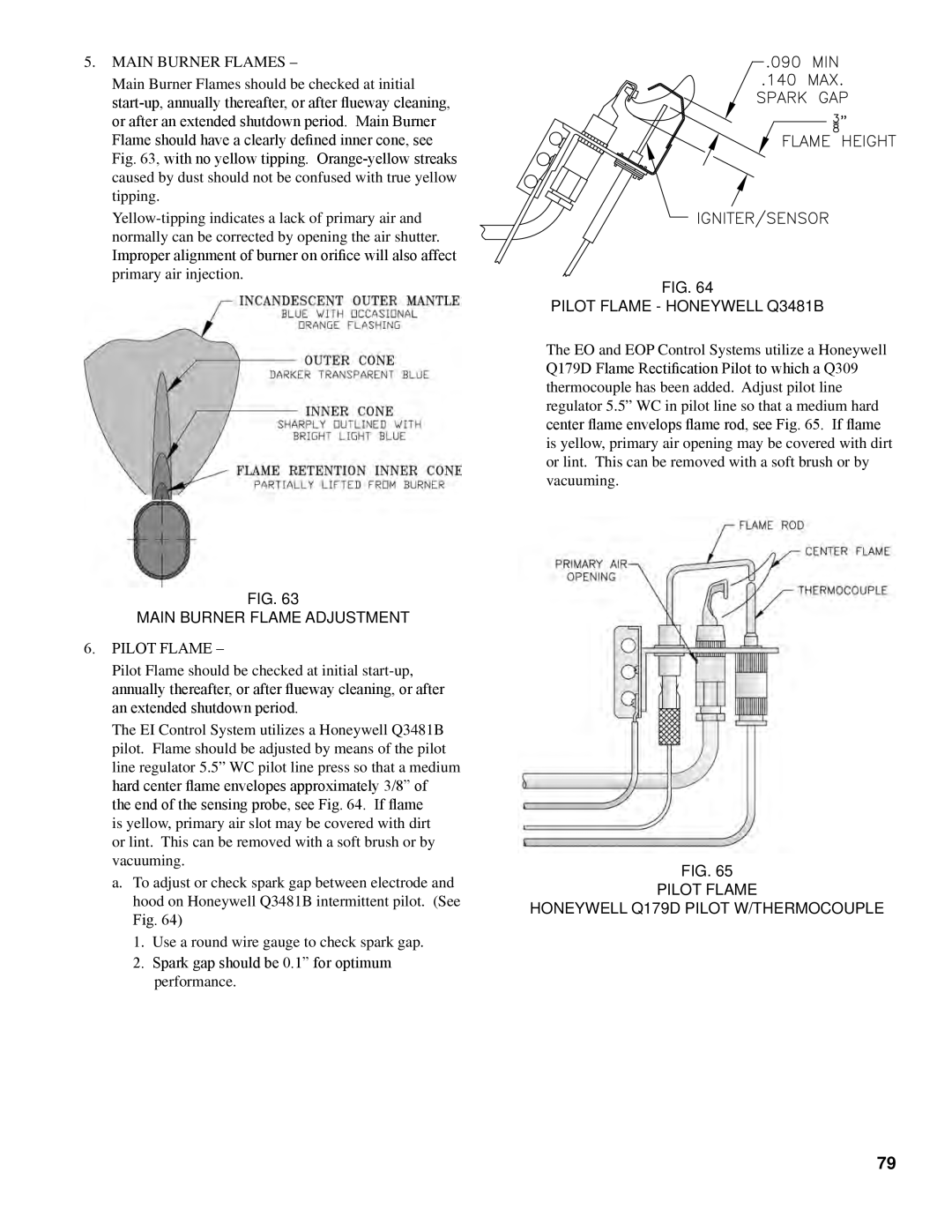

Fig. 64

PILOT FLAME - HONEYWELL Q3481B

The EO and EOP Control Systems utilize a Honeywell Q179D Flame Rectification Pilot to which a Q309 thermocouple has been added. Adjust pilot line regulator 5.5” WC in pilot line so that a medium hard center flame envelops flame rod, see Fig. 65. If flame is yellow, primary air opening may be covered with dirt or lint. This can be removed with a soft brush or by vacuuming.

Fig. 63

MAIN BURNER FLAME ADJUSTMENT

6.PILOT FLAME –

Pilot Flame should be checked at initial

The EI Control System utilizes a Honeywell Q3481B pilot. Flame should be adjusted by means of the pilot line regulator 5.5” WC pilot line press so that a medium hard center flame envelopes approximately 3/8” of the end of the sensing probe, see Fig. 64. If flame

is yellow, primary air slot may be covered with dirt or lint. This can be removed with a soft brush or by vacuuming.

a.To adjust or check spark gap between electrode and hood on Honeywell Q3481B intermittent pilot. (See

Fig. 64)

1.Use a round wire gauge to check spark gap.

2.Spark gap should be 0.1” for optimum performance.

Fig. 65

PILOT FLAME

HONEYWELL Q179D PILOT w/THERMOCOUPLE

79