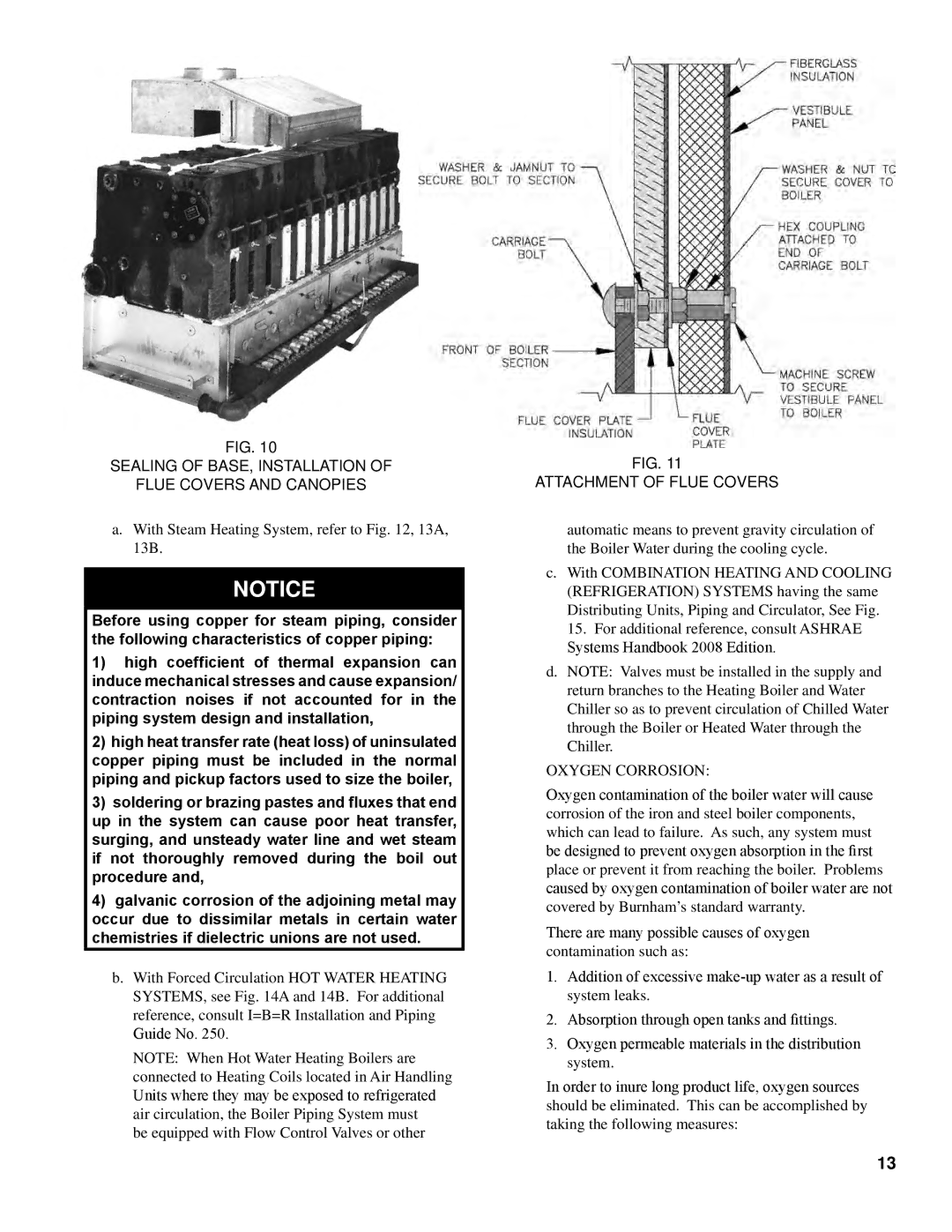

Fig. 10

SEALING OF BASE, INSTALLATION OF

FLUE COVERS AND CANOPIES

a.With Steam Heating System, refer to Fig. 12, 13A, 13B.

NOTICE![]()

Before using copper for steam piping, consider the following characteristics of copper piping:

1)high coefficient of thermal expansion can induce mechanical stresses and cause expansion/ contraction noises if not accounted for in the piping system design and installation,

2)high heat transfer rate (heat loss) of uninsulated copper piping must be included in the normal piping and pickup factors used to size the boiler,

3)soldering or brazing pastes and fluxes that end up in the system can cause poor heat transfer, surging, and unsteady water line and wet steam if not thoroughly removed during the boil out procedure and,

4)galvanic corrosion of the adjoining metal may occur due to dissimilar metals in certain water chemistries if dielectric unions are not used.

b.With Forced Circulation HOT WATER HEATING SYSTEMS, see Fig. 14A and 14B. For additional reference, consult I=B=R Installation and Piping

Guide No. 250.

NOTE: When Hot Water Heating Boilers are connected to Heating Coils located in Air Handling

Units where they may be exposed to refrigerated air circulation, the Boiler Piping System must be equipped with Flow Control Valves or other

Fig. 11

ATTACHMENT OF FLUE COVERS

automatic means to prevent gravity circulation of the Boiler Water during the cooling cycle.

c.With COMBINATION HEATING AND COOLING (REFRIGERATION) SYSTEMS having the same Distributing Units, Piping and Circulator, See Fig. 15. For additional reference, consult ASHRAE

Systems Handbook 2008 Edition.

d.NOTE: Valves must be installed in the supply and return branches to the Heating Boiler and Water Chiller so as to prevent circulation of Chilled Water through the Boiler or Heated Water through the Chiller.

OXYGEN CORROSION:

Oxygen contamination of the boiler water will cause corrosion of the iron and steel boiler components, which can lead to failure. As such, any system must be designed to prevent oxygen absorption in the first place or prevent it from reaching the boiler. Problems caused by oxygen contamination of boiler water are not covered by Burnham’s standard warranty.

There are many possible causes of oxygen contamination such as:

1.Addition of excessive

2.Absorption through open tanks and fittings.

3.Oxygen permeable materials in the distribution system.

In order to inure long product life, oxygen sources should be eliminated. This can be accomplished by taking the following measures:

13