32.Tighten all sheet metal screws.

a.Install the following plates or labels which are found in the Instruction Envelope. See Fig. 23 or 24 for location.

(1)Rating Label

(2)Operating Instruction Plate (#8 SMS required to fasten)

(3)Combustible Clearance Flooring & Adequate Combustion Plate

(4)Minimum Service Clearance Label

(5)Burnham Logo – Apply to Top Panel

(6)Boiler Ventilation/For Your Safety Label

b.Proceed to Paragraph 33 (Steam Boilers) or Paragraph 34 (Water Boilers).

NOTE: IF WATER BOILER, PROCEED DIRECTLY TO Paragraph 34.

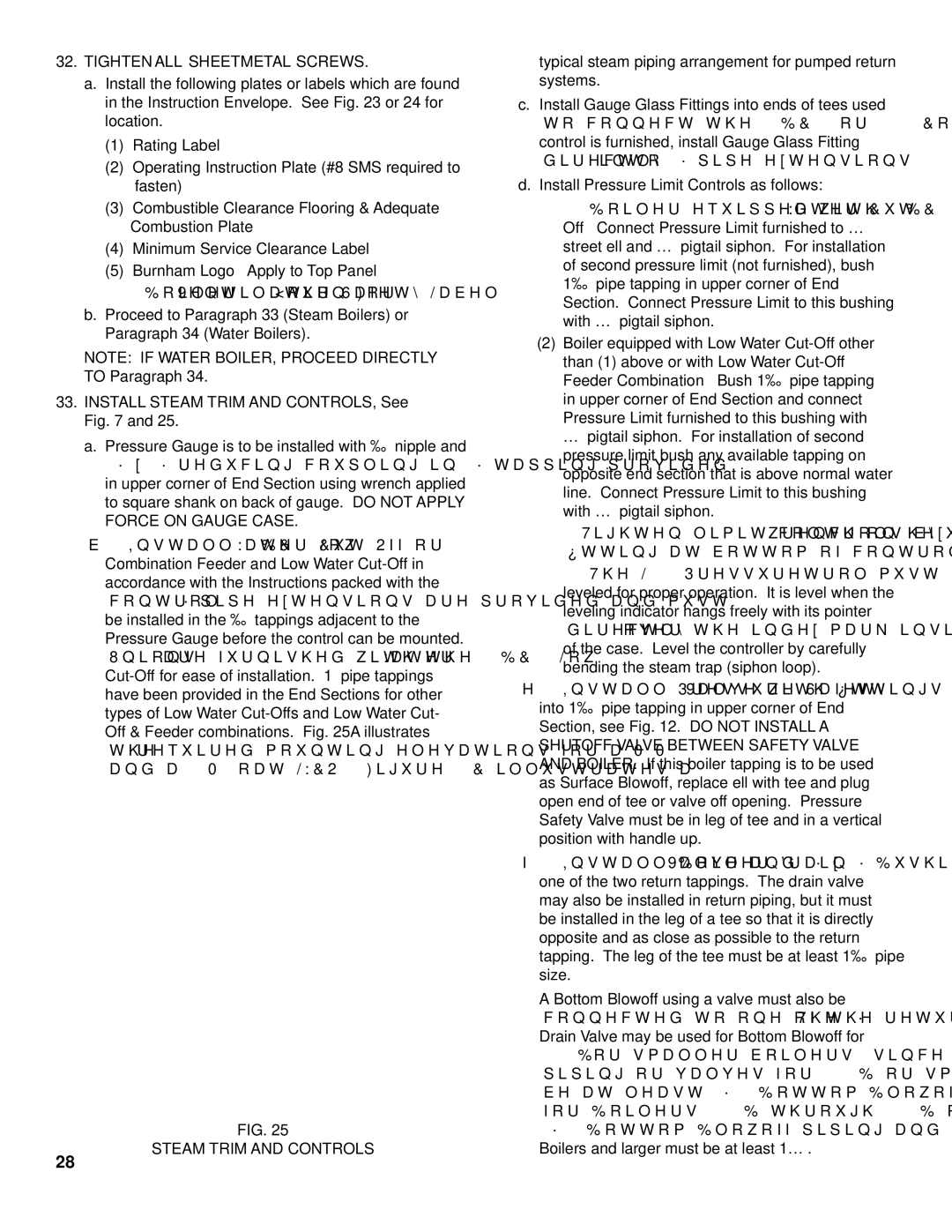

33.INSTALL STEAM TRIM AND CONTROLS, See Fig. 7 and 25.

a.Pressure Gauge is to be installed with ½” nipple and

½” x ¼” reducing coupling in ½” tapping provided in upper corner of End Section using wrench applied to square shank on back of gauge. DO NOT APPLY FORCE ON GAUGE CASE.

b.Install

Combination Feeder and Low Water

Unions are furnished with the

typical steam piping arrangement for pumped return systems.

c. | Install Gauge Glass Fittings into ends of tees used | |

| to connect the | |

| control is furnished, install Gauge Glass Fitting | |

| directly into ½” pipe extensions. | |

d. Install Pressure Limit Controls as follows: | ||

| (1) | Boiler equipped with |

|

| Off – Connect Pressure Limit furnished to ¼” |

|

| street ell and ¼” pigtail siphon. For installation |

|

| of second pressure limit (not furnished), bush |

|

| 1½” pipe tapping in upper corner of End |

|

| Section. Connect Pressure Limit to this bushing |

|

| with ¼” pigtail siphon. |

| (2) | Boiler equipped with Low Water |

|

| than (1) above or with Low Water |

|

| Feeder Combination – Bush 1½” pipe tapping |

|

| in upper corner of End Section and connect |

|

| Pressure Limit furnished to this bushing with |

|

| ¼” pigtail siphon. For installation of second |

|

| pressure limit bush any available tapping on |

|

| opposite end section that is above normal water |

|

| line. Connect Pressure Limit to this bushing |

|

| with ¼” pigtail siphon. |

| (3) | Tighten limit controls by using wrench on hex |

|

| fitting at bottom of control. |

| (4) | The L404 Pressuretrol must be accurately |

|

| leveled for proper operation. It is level when the |

|

| leveling indicator hangs freely with its pointer |

|

| directly over the index mark inside the back |

|

| of the case. Level the controller by carefully |

|

| bending the steam trap (siphon loop). |

e. | Install Pressure Safety Valve with fittings furnished, | |

| into 1½” pipe tapping in upper corner of End | |

| Section, see Fig. 12. DO NOT INSTALL A | |

| SHUTOFF VALVE BETWEEN SAFETY VALVE | |

| AND BOILER. If this boiler tapping is to be used | |

| as Surface Blowoff, replace ell with tee and plug | |

| open end of tee or valve off opening. Pressure | |

| Safety Valve must be in leg of tee and in a vertical | |

| position with handle up. | |

f. | Install Boiler Drain Valve and 3” x ¾” Bushing into | |

| one of the two return tappings. The drain valve | |

| may also be installed in return piping, but it must | |

| be installed in the leg of a tee so that it is directly | |

| opposite and as close as possible to the return | |

| tapping. The leg of the tee must be at least 1½” pipe | |

| size. | |

| A Bottom Blowoff using a valve must also be | |

| connected to one of the return tappings. The ¾” | |

| Drain Valve may be used for Bottom Blowoff for | |

| 5009B or smaller boilers, since any Bottom Blowoff | |

| piping or valves for 5009B or smaller boilers must | |

| be at least ¾”. Bottom Blowoff piping and valves | |

| for Boilers 5010B through 5021B must be at least | |

28

Fig. 25

STEAM TRIM AND CONTROLS

1”. Bottom Blowoff piping and valves for 5022B |

Boilers and larger must be at least 1¼”. |