|

| • | Check host adapter and SCSI cables and terminator. | |

|

| • | Power cycle the autoloader and retry the operation. | |

|

| • | If all previous steps fail, contact support.dell.com. | |

|

|

|

| |

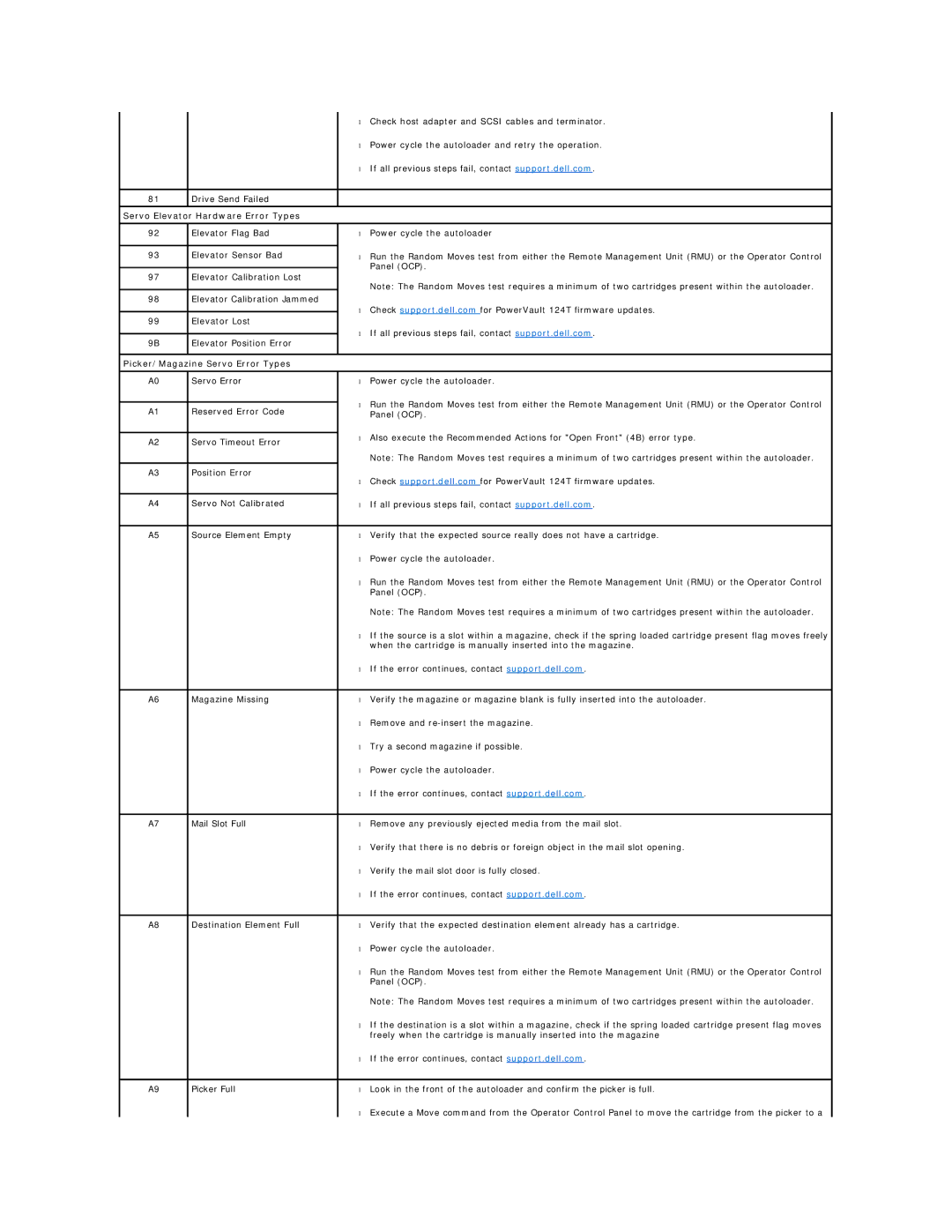

81 | Drive Send Failed |

|

| |

|

|

|

| |

Servo Elevator Hardware Error Types |

|

| ||

|

|

|

| |

92 | Elevator Flag Bad | • | Power cycle the autoloader | |

|

|

|

| |

93 | Elevator Sensor Bad | • | Run the Random Moves test from either the Remote Management Unit (RMU) or the Operator Control | |

|

|

| Panel (OCP). | |

97 | Elevator Calibration Lost |

| ||

| Note: The Random Moves test requires a minimum of two cartridges present within the autoloader. | |||

|

|

| ||

98 | Elevator Calibration Jammed |

|

| |

|

| • | Check support.dell.com for PowerVault 124T firmware updates. | |

99 | Elevator Lost | |||

|

| |||

|

| • | If all previous steps fail, contact support.dell.com. | |

9B | Elevator Position Error | |||

|

| |||

|

|

|

| |

Picker/Magazine Servo Error Types |

|

| ||

|

|

|

| |

A0 | Servo Error | • | Power cycle the autoloader. | |

|

| • | Run the Random Moves test from either the Remote Management Unit (RMU) or the Operator Control | |

A1 | Reserved Error Code | |||

| Panel (OCP). | |||

|

|

| ||

|

| • | Also execute the Recommended Actions for "Open Front" (4B) error type. | |

A2 | Servo Timeout Error | |||

|

| |||

|

|

| Note: The Random Moves test requires a minimum of two cartridges present within the autoloader. | |

A3 | Position Error |

| Check support.dell.com for PowerVault 124T firmware updates. | |

|

| • | ||

|

|

|

| |

A4 | Servo Not Calibrated | • | If all previous steps fail, contact support.dell.com. | |

|

|

|

| |

A5 | Source Element Empty | • | Verify that the expected source really does not have a cartridge. | |

|

| • | Power cycle the autoloader. | |

|

| • | Run the Random Moves test from either the Remote Management Unit (RMU) or the Operator Control | |

|

|

| Panel (OCP). | |

|

|

| Note: The Random Moves test requires a minimum of two cartridges present within the autoloader. | |

|

| • | If the source is a slot within a magazine, check if the spring loaded cartridge present flag moves freely | |

|

|

| when the cartridge is manually inserted into the magazine. | |

|

| • | If the error continues, contact support.dell.com. | |

|

|

|

| |

A6 | Magazine Missing | • | Verify the magazine or magazine blank is fully inserted into the autoloader. | |

|

| • | Remove and | |

|

| • | Try a second magazine if possible. | |

|

| • | Power cycle the autoloader. | |

|

| • | If the error continues, contact support.dell.com. | |

|

|

|

| |

A7 | Mail Slot Full | • | Remove any previously ejected media from the mail slot. | |

|

| • | Verify that there is no debris or foreign object in the mail slot opening. | |

|

| • | Verify the mail slot door is fully closed. | |

|

| • | If the error continues, contact support.dell.com. | |

|

|

|

| |

A8 | Destination Element Full | • | Verify that the expected destination element already has a cartridge. | |

|

| • | Power cycle the autoloader. | |

|

| • | Run the Random Moves test from either the Remote Management Unit (RMU) or the Operator Control | |

|

|

| Panel (OCP). | |

|

|

| Note: The Random Moves test requires a minimum of two cartridges present within the autoloader. | |

|

| • | If the destination is a slot within a magazine, check if the spring loaded cartridge present flag moves | |

|

|

| freely when the cartridge is manually inserted into the magazine | |

|

| • | If the error continues, contact support.dell.com. | |

|

|

|

| |

A9 | Picker Full | • | Look in the front of the autoloader and confirm the picker is full. | |

|

| • | Execute a Move command from the Operator Control Panel to move the cartridge from the picker to a | |

Page 47

Image 47