World Class 3000

Instruction Manual

6-8 PERFORMANCE PROBLEM (PROCESS RESPONSE IS SUSPECT)

O2 readings may not always agree with known process conditions. Such a discrepancy can be the first sign of a problem either in the process or the World Class 3000. The O2 display will

read between 0 to 99%, but the reading may be unstable. The status line may read OK, and PROBE DATA voltages may read normal.

Refer to Table

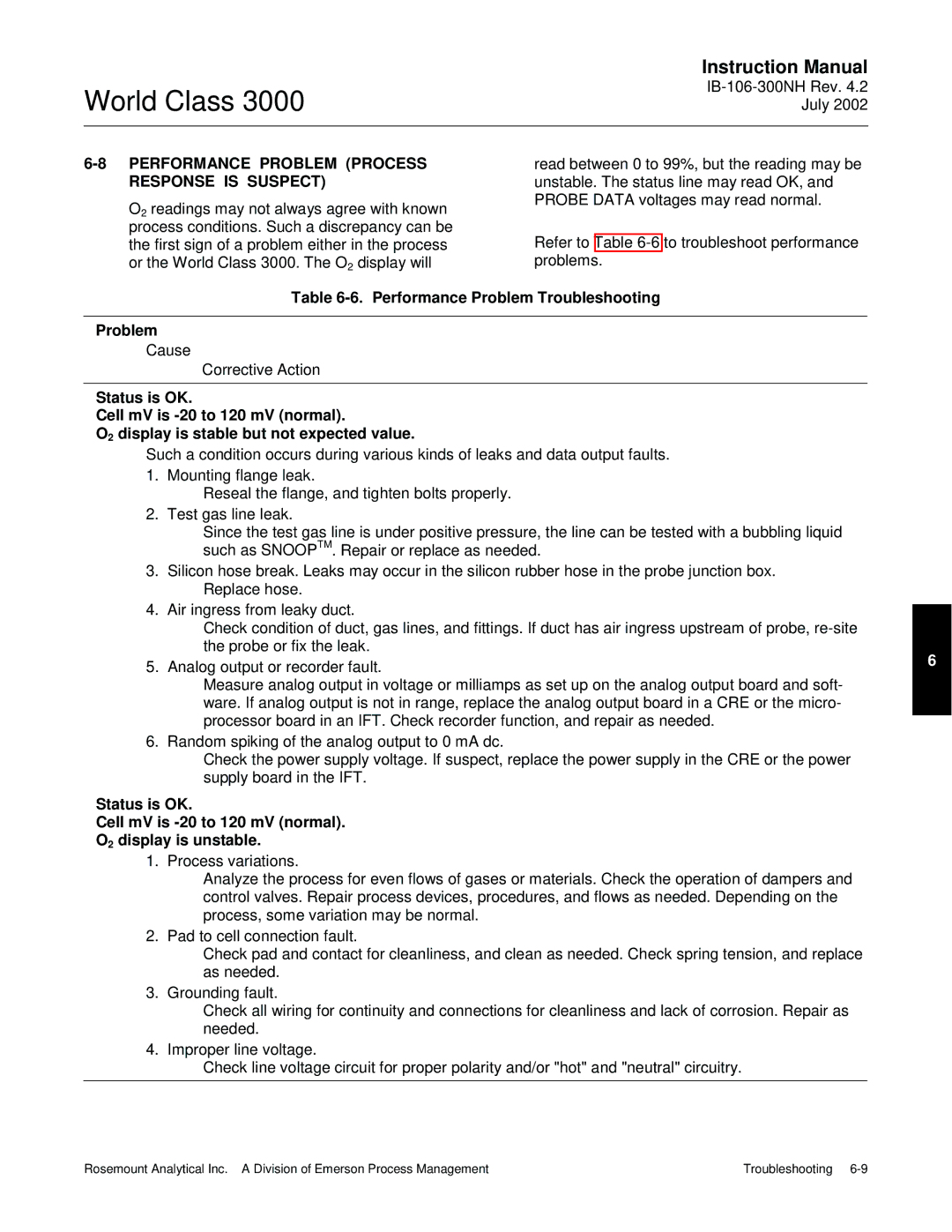

Table 6-6. Performance Problem Troubleshooting

Problem

Cause

Corrective Action

Status is OK.

Cell mV is

O2 display is stable but not expected value.

Such a condition occurs during various kinds of leaks and data output faults.

1. | Mounting flange leak. |

| |

| Reseal the flange, and tighten bolts properly. |

| |

2. | Test gas line leak. |

| |

| Since the test gas line is under positive pressure, the line can be tested with a bubbling liquid |

| |

| such as SNOOPTM. Repair or replace as needed. |

| |

3. | Silicon hose break. Leaks may occur in the silicon rubber hose in the probe junction box. |

| |

| Replace hose. |

| |

4. | Air ingress from leaky duct. |

| |

| |||

| Check condition of duct, gas lines, and fittings. If duct has air ingress upstream of probe, |

| |

| the probe or fix the leak. | 6 | |

5. | Analog output or recorder fault. | ||

| |||

| Measure analog output in voltage or milliamps as set up on the analog output board and soft- |

| |

| ware. If analog output is not in range, replace the analog output board in a CRE or the micro- |

| |

| processor board in an IFT. Check recorder function, and repair as needed. |

| |

6. | Random spiking of the analog output to 0 mA dc. |

| |

| Check the power supply voltage. If suspect, replace the power supply in the CRE or the power |

| |

| supply board in the IFT. |

|

Status is OK.

Cell mV is

O2 display is unstable.

1. Process variations.

Analyze the process for even flows of gases or materials. Check the operation of dampers and control valves. Repair process devices, procedures, and flows as needed. Depending on the process, some variation may be normal.

2. Pad to cell connection fault.

Check pad and contact for cleanliness, and clean as needed. Check spring tension, and replace as needed.

3. Grounding fault.

Check all wiring for continuity and connections for cleanliness and lack of corrosion. Repair as needed.

4. Improper line voltage.

Check line voltage circuit for proper polarity and/or "hot" and "neutral" circuitry.

Rosemount Analytical Inc. A Division of Emerson Process Management | Troubleshooting |