Innovation Series

Page

Publication GEH-6385 Issued

Page

Safety Symbol Legend

Page

Contents

Page

Wizards

Page

Appendix a Function Block Diagrams

Page

Overview

Introduction

Using Toolbox Help for Reference and Troubleshooting

GE document GEH-6401 describes toolbox features and use

How to Get Help

Related Documents

Page

Faults and Troubleshooting

Types of Faults

Fault Indication

Fault Descriptions

Cpfp isolation lost

Illegal seq state

Failed to close

Main Contactor Configuration

Speed Control Fault Check

MA pickup time

Name Type Description

Sequencer Permissives

Aborted

Illegal req for xfer

Transfer req

Tune up failed

Power Dip Protection

Than the power dip time, Power dip occurs

Should be set equal to 0.500 sec Enable

Large motor parameters errors

Operator

Required

Connections between Fosa and Shca

Power supply module failure

Card or connector failure

Short across one of the monitored power supplies

Ground fault in the input rectifier section

Ground flt alm, LP

Gnd signal alarm on, is too low

DC bus under

Ground flt, LP

Request, or Full flux request

Stopping Commands and Modes

Ambient temperature is too low

Equal to Unused

Thermal sensor input to Tfba is missing or damaged

No power to Tfba card or Tfba card failure

DS heatsink thermal sensor input is not present

Ambient thermal sensor input is not present

DB resistor package is marginal for application

Incorrect configuration of DB thermal model

Ambient temperature is too high

Stator lkg react X1 Starting react Xst

Switchgear not racked

Customer switchgear permissive not met

Heatsink thermal sensor input is not present

Run permissive lost Alarm

HtSink temp Trip

Heatsink thermal sensor is defective

AC line voltage is excessive

Value of 90% of nominal

AC line voltage too low

Suggested value of 88% of nominal

AC line voltage is marginally low

AC line frequency is marginally excessive

Frequency was at 50hz

Switchgear tripped

Switchgear defective

Switchgear opened via external command

AC line frequency is transiently low

Temperature to rise above a safe operating level

Bridge environment and running conditions cause the ambient

Pulse off time, Pulse 2 on time, Post pulse off time

Pulse tst config bad

Voltage offset

Ckt board list fail

Task 2 exec

Task 1 exec

Overrun

Task 3 exec

Ain 1 signal trip

Ain 1 signal alarm

Analog in 1 flt mode

Analog in 1 flt lev

Ain 2 signal trip

Ain 2 signal alarm

Analog in 2 flt mode

Analog in 2 flt lev

Start permissive

DBS1 Igdm card flt

DBS2 Igdm card flt

AS1 Igdm card flt

AS2 Igdm card flt

AS3 Igdm card flt

AS4 Igdm card flt

BS1 Igdm card flt

BS2 Igdm card flt

BS3 Igdm card flt

BS4 Igdm card flt

CS1 Igdm card flt

CS2 Igdm card flt

CS3 Igdm card flt

CS4 Igdm card flt

AC line transient

AC line watchdog

AC line rev phs seq

Motor OT fault sel

Parameter Motor OT fault sel

Motor Overtemperature Detection

AC line vfb offset

Customer use NC

Parameter User NC fault sel

Parameter User no fault sel

Flt

Reverse rotation

LAN alarm request

DSPx Watchdog

Failure to rotate

System ISBus error

Motor rated power, Not entered

Motor service factor, Not entered

LAN watchdog

No. Name Type Description

Frame PLL not OK

Paramters/Functions

Page

Motor winding cfg 114 Preflux Forcing

Capture Buffer

Diagnostic and Utility Functions

Diagnostic and Utility Overview

Function Inputs

Function Outputs

Variable Description

Not stopped Stopped is False. If Cap re-enable delay

Function Configuration

Channels enabled

Parameter Description

Value in Capture trig level

Than value in Capture trig level

Function description

Related diagrams

Capture Buffer Compatible Behavior

General Purpose Constants

VariableDescription

General Purpose Filters

Output = Bandwidth ⋅ Input + Bandwidth

Oscillator

Position Feedback

Integer constants

Predefined Constants

Floating point constants

Boolean constants

Signal Level Detector SLD

SLD1 compare mode = In1-In2Sen

SLD1 compare mode = In1In2

SLD1 input 1 abs val SLD1 Input Values

SLD1 compare mode = In1=In2

SLD1 compare mode = In1-In2Sen one shot

Simulator

Control Diagnostic Variables

Line Simulator

Drive Configuration Functions

Intelligent Part Number IPN

Product field

Primary Motor & Application Data

Reflected indication variables

Calculated control variables

Display meter scaling parameters

General Setup Functions

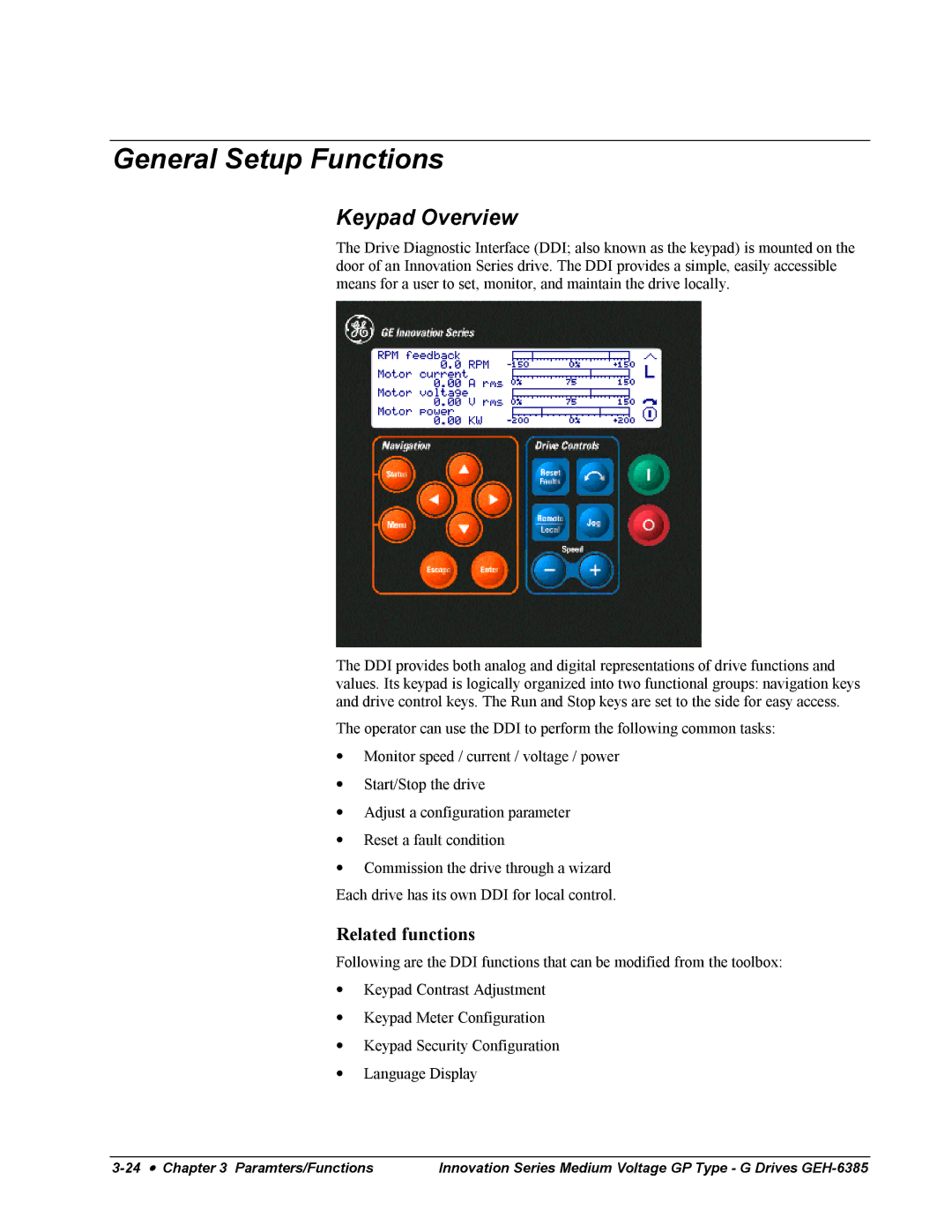

Keypad Overview

Related functions

Keypad Contrast Adjustment

Keypad Meter Configuration

Function configuration

Keypad Security Configuration

Password

Language and Units Presentation

Menu functions

Display units Length Power Torque Flux

Language Display

Analog and Digital I/O Testing

Functions

Analog inputs

Hi-fi counters

Local and system fault strings

Digital inputs

Contactor status

Analog Inputs/Outputs and Mapping

Relay outputs

Digital Inputs/Outputs and Mapping

Ctbc Output Pre-programmed function

LAN Functions

Frame Phaselock Loop

Phaselock Loop

LAN Overview

LAN Configuration and Health

Configuration parameters

Heartbeat fbk, lan signal

Diagnostic variables

LAN heartbeat trip and LAN heartbeat alarm

Frame Phaselock Loop

LAN Signal Map

Speed Reference Generation

Signal Data Description Element Type

LAN References

Speed/Torque Regulator function

Bit Signal Description

Used in the Speed Reference Generation function

Used in the Motor Control Interface function

LAN Feedbacks

Level Zero speed level

Sel

Related diagrams

Motor Control Functions

Motor Control Overview

Flux Curve

Leakage Inductance Curve

Line Transfer

General operation

Motor transfer functionality

Motor capture functionality

Motor Equivalent Circuit

External line reference functionality

Motor Temperature Estimation

Power Dip Protection

Value of Power dip control Expiration time

Faults and alarms

Fault Description

Tach Loss Detection

Variable Description

Custom User Faults

Fault/Alarm Description

Protective Functions

Fault/AlarmDescription

Occurs when Gnd current, coarse Gnd flt

Ground Fault Protection Fast

Fault / Alarm Description

Coarse trip

Hardware Fault Strings

Input signal connection

Heatsink Thermal Protection

Related faults and alarms

Line-Line Voltage Protection

Variable Bridge ambient temp

Motor Overtemperature Detection

Phase Current Protection

Parameter Motor OT fault mode is set to Trip flt

Parameter Motor OT fault mode is set to Alarm fault

Timed Overcurrent Detection

Faults and alarms

Page

Page

Transformer Overtemperature Detection

Alarm fault

Enabled. The Ground flt alm, LP alarm and Gnd flt trip trip

Alarm, Ground flt alm, LP is present

When set to Enable, the Motor Ground Protection function is

Motor Ground Protection

Trip fault occurs if Gnd cur signal = Gnd signal trip lvl

Alarm is present when Gnd cur signal = Gnd signal alarm

Alarm off

Ground flt alm, LP is present

Phase Imbalance Monitor

Line magnitude

Line Monitor Overview OvrLinMon

Line Monitor

Phase Imbalance Monitor Phase Lock Loop

Phase Lock Loop

Magnitude, AC line voltage mag

Voltage and X axis line voltage

Sequencer Functions

Fault Reset Logic

Reset select to be active

Sequencer Overview

General Sequencing #1 GenSeq1

Sequencer Permissives

Populates Run permissive

Strings

Normal stop mode is set to Quick stop or Coast stop. Also

See Stopping Commands and Modes

This parameter removes Coast stop active and Quick stop

Stopping Commands and Modes

Related faults and alarms

Request, lan to set Run request to True and at Stop PB

Commands

Request to True and at Stop PB request to set Run

Request to set Run request to False

Level , unless Flying restart is enabled

Speed reg fbk has reached the Zero speed level ,

Zero speed level , unless Flying restart is enabled

Commands OK is True. X stop request, lan must be True to

Behavior of X stop request sel. See also LAN Signal Map

Function output

Run request. See Stopping Commands and Modes for more

Sequencer Commands

Stopping Commands and Modes for more information on Stop PB

Select

Standby command

Also see LAN Signal Map

See Local Speed Reference or Remote Speed Reference for

Is used to measure the value of motor parameters that are

See Sequencer Permissives

Normal or X-stop. See Stopping Commands and Modes

Sequencer Status

Permissives

Sequencer status variables

Speed/Torque Regulator

Main Contactor Configuration

Function input

General Sequencing #4 GenSeq4

Speed Limit function variable Min speed output . RPM

Speed Reference Functions

Critical Speed Avoidance

Speed ref, pre ramp . RPM

Local Speed Reference

Speed Avoidance Zone Center Speed

Minimum Speed Limit

Avoidance function variable Speed avd func input. RPM

Remote Speed Reference

Speed ref sel is False

Manual speed ref sel is True. RPM

Speed Reference Generation

Stopping Commands and Modes signal that indicates

Speed Reference Ramp

Avoidance function variable Spd avd func output. RPM

Break point 1 and Accel break point 2. RPM/second

Break point 1. RPM/second

Between Acceleration rate 1 and Acceleration rate

Between Acceleration rate 2 and Acceleration rate

Ramp rate Active region

Speed Reference Reverse

Speed Reference Generation OvrRfSel

Speed/Torque Control Functions

Droop

Motor Control Interface

Enable req. RMS amps

Function configuration

Speed Control Fault Check

Over speed configuration and operation

Failure to rotate configuration and operation

Loss of spd control configuration and operation

Reverse rotation configuration and operation

Speed Feedback Calculation

Function control outputs

Function display outputs

Speed/Torque Overview

Speed Reference Generation function. RPM

Speed/Torque Regulator

Net gain

Error only in Torque, spd override mode see below

Between Speed reg reference and Speed reg fbk. RPM

Output

Ovrd/Spd forced mode within Torque, spd override modes

Act to Ovrd/Spd Low

Act to Ovrd/Spd High

Spd reg pos err lim & Spd reg neg err lim

Active Torque, spd override mode

Regulator function

Speed reg output is zeroed, and Torque ref input is

Specified by Spd reg pos err lim

Forced Torque, spd override mode

Sel is False, or the Torque reg stop mode is

Specified by Spd reg neg err lim

Motor ctrl alg sel

System Data Parameters

Exec time/Chop freq

Values

Motor efficiency

Functional use

Units

Motor service factor

Motor winding cfg

Preflux Forcing

Wizards

Page

Page

Fiber-Optic Test

Cell Test Wizard

Cell Test Options

Bridge Cell Test

Physical Diagram of Correct LED Lighting Sequence

Running the Test

Troubleshooting

Problem Description

Following are descriptions of error messages

Error Message Description/Procedure

Running the Bridge Cell Test

Following are descriptions of bridge test failure messages

DAC Setup

Following are descriptions of error messages

Drive Commissioning Intelligent Part Number

Drive Commissioning

Drive Commissioning Overview

Drive Commissioning Drive Units

Drive Commissioning AC Source Selection

Drive Commissioning Motor Nameplate Data

Related elementaries

Drive Commissioning Motor Protection Class

Drive Commissioning Motor Data Sheet

Drive Commissioning Motor Crossover Voltage

Drive Commissioning Motor Poles

Drive Commissioning Motor Data Sheet Equivalent Circuit Data

Flux Curve Data from Motor Data Sheet

Drive Commissioning Motor and Process Speed Referencing

Drive Commissioning Tachometer Support

Drive Commissioning Tachometer Pulses Per Revolution

Drive Commissioning Stopping Configuration

Value of Normal stop Behavior Mode

Drive Commissioning Flying Restart

Drive Commissioning X-Stop Configuration

Value of X stop mode Behavior

Drive Commissioning X-Stop Ramp Time

Drive Commissioning Manual Reference

Drive Commissioning Run Ready Permissive String

Drive Commissioning Starting and Stopping the Drive

Run request

Drive Commissioning Jog Speed Setpoints

Drive Commissioning Reference Ramp Mode

Drive Commissioning Maximum Speed References

Drive Commissioning Reference Ramp Bypass

Drive Commissioning Reference Ramp Speed Independent Rates

Related functions

Drive Commissioning Speed/Torque Regulator Configuration

Drive Commissioning Speed/Torque Regulator Modes

Drive Commissioning Torque with Speed Override Speed Error

Drive Commissioning Torque Regulator Reference and Output

Drive Commissioning Torque and Current Limits

Drive Commissioning Torque and Current Limits Uniform

Drive Commissioning Normal Torque and Current Limits

Drive Commissioning Failed Calculation

Drive Commissioning Torque and Current Limit Selection

Drive Commissioning Alternate Torque and Current Limits

Drive Commissioning Simulator Mechanical Configuration

Drive Commissioning Power Dip Ride-Through

Drive Commissioning Simulator Mode

Drive Commissioning Current Limits

Drive Commissioning Conclusion

Line Transfer Tuneup

Drive Commissioning Exit Reminder

Line Transfer Tuneup Overview

Line Transfer Tuneup Motor Capture Data

Line Transfer Tuneup Operation

Display Description

Motor Control Tuneup

Motor Control Tuneup Equivalent Circuit

Motor Control Tuneup Measurements

Panel Meter Setup

Per Unit Setup

Motor Control Tuneup Operation

Line Protection Introduction

Line Protection Setup

Line Protection Default Settings

Line Protection Overvoltage

Line Protection Underfrequency

Pulse Test

Line Protection Overfrequency

Line Protection Conclusion

Pulse Test Analog Output Configuration

Pulse Test Bridge State Configuration

Park phase Park level

Pulse phase Pulse level

Bridge State Description

Pulse Test Operation

Remaining Parameter Setup

Pulse Test Timer Configuration

Pulse Mid pulse Post pulse On time Off time

Simulator Setup

Speed Regulator Tuneup

Speed Regulator Tuneup Model

Speed Regulator Tuneup System Inertia

Speed Regulator Tuneup 1st Order Response

Speed Regulator Tuneup Speed Regulator Mode

Speed Regulator Tuneup Manual Regulator Tuneup

Speed Regulator Tuneup 2nd Order Response

Page

Page

Signal Mapping

LAN Interfaces

Interface Module Communications Supported

Parameter Configuration for Signal Mapping

LAN

Variable Mapping

Type Direction of Data

Data Type Format

Applying the LAN Heartbeat Echo Feature

Heartbeat Echo Function with a PLC

Application of Feedback Signals

Variable Maps

Real Variable Map

Reference Feedback Byte Variable Functionality

Boolean Variable Map

Ramp bypass req Bypass ramp

Lan RmpBypass

LanRmpByp

Page

Appendix a Function Block Diagrams

SLD

ACMVAC-G Inverter Overview

Drive Feedbacks & Status

ACMVAC-G Inverter Index

Digital Inputs/Outputs & Mapping

Digital Inputs Sequencing Selectors Relay Outputs

Analog Inputs/Outputs & Mapping

Drive Lan Signal Map

Status Configuration

Drive Lan Boolean Signals bits

Status

Back Back to SigMapBit1 SigMapLAN

Line Monitor Overview

Phase Lock Loop Regulator

Sequencing Overview

Index

General Sequencing #1

General Sequencing #2

General Sequencing #3

General Sequencing #4

General Sequencing #5

Speed Reference Generation

Critical Speed

Speed Reference Ramp

To Speed Regulator Generation OvrRfSel

Speed / Torque Overview

Speed Regulator Motor Control Interface

Speed Feedback

Motor Tach Speed Feedback

Speed Regulator

State

Droop

Back OvrSpTq Deadband

Motor Control Interface

Motoring & Generating Torque Limit Select

Motor Control

Diagnostic & Utility Functions

General Purpose Oscillator Constants

General Purpose Filters

Signal Level Detection

Capture Buffer Configuration

Capture Buffer

Position Feedback Instrument

Index

Page

GEH-6385 Reference and Troubleshooting, 2300 V Drives Index

Page

GEH-6385 Reference and Troubleshooting, 2300 V Drives Index

Page

GEH-6385 Reference and Troubleshooting, 2300 V Drives Index

Page

GEH-6385 Reference and Troubleshooting, 2300 V Drives Index

Page

GEH-6385 Reference and Troubleshooting, 2300 V Drives Index

Page

HQHUDOOHFWULF&RPSDQ\5HDGHU&RPPHQWV

QGXVWULDO6\VWHPV

Page

ZZZ*LQGXVWULDOFRP