BASIC OPERATION AND FEATURES

SX TRANSISTOR CONTROL | Page 4 |

Section 1. INTRODUCTION

Section 1.1 Motor Characteristics

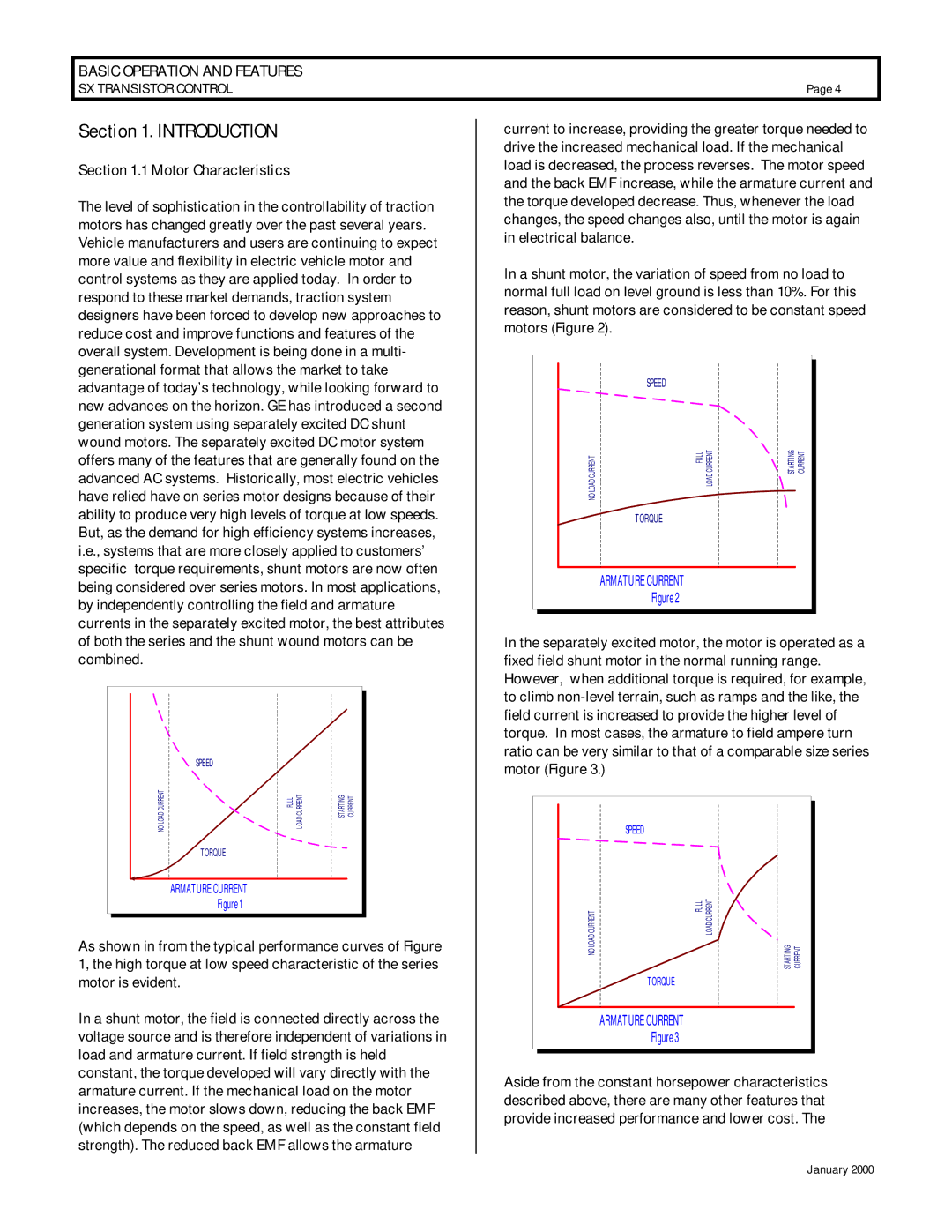

The level of sophistication in the controllability of traction motors has changed greatly over the past several years. Vehicle manufacturers and users are continuing to expect more value and flexibility in electric vehicle motor and control systems as they are applied today. In order to respond to these market demands, traction system designers have been forced to develop new approaches to reduce cost and improve functions and features of the overall system. Development is being done in a multi- generational format that allows the market to take advantage of today’s technology, while looking forward to new advances on the horizon. GE has introduced a second generation system using separately excited DC shunt wound motors. The separately excited DC motor system offers many of the features that are generally found on the advanced AC systems. Historically, most electric vehicles have relied have on series motor designs because of their ability to produce very high levels of torque at low speeds. But, as the demand for high efficiency systems increases, i.e., systems that are more closely applied to customers’ specific torque requirements, shunt motors are now often being considered over series motors. In most applications, by independently controlling the field and armature currents in the separately excited motor, the best attributes of both the series and the shunt wound motors can be combined.

| SPEED |

|

|

NO LOAD CURRENT | FULL | LOAD CURRENT | STARTING CURRENT |

| TORQUE |

|

|

| ARMATURE CURRENT |

|

|

| Figure 1 |

|

|

As shown in from the typical performance curves of Figure 1, the high torque at low speed characteristic of the series motor is evident.

In a shunt motor, the field is connected directly across the voltage source and is therefore independent of variations in load and armature current. If field strength is held constant, the torque developed will vary directly with the armature current. If the mechanical load on the motor increases, the motor slows down, reducing the back EMF (which depends on the speed, as well as the constant field strength). The reduced back EMF allows the armature

current to increase, providing the greater torque needed to drive the increased mechanical load. If the mechanical load is decreased, the process reverses. The motor speed and the back EMF increase, while the armature current and the torque developed decrease. Thus, whenever the load changes, the speed changes also, until the motor is again in electrical balance.

In a shunt motor, the variation of speed from no load to normal full load on level ground is less than 10%. For this reason, shunt motors are considered to be constant speed motors (Figure 2).

| SPEED |

|

|

LOAD CURRENT | FULL | LOAD CURRENT | STARTING CURRENT |

NO |

|

|

|

| TORQUE |

|

|

ARMATURE CURRENT

Figure 2

In the separately excited motor, the motor is operated as a fixed field shunt motor in the normal running range. However, when additional torque is required, for example, to climb

| SPEED |

|

|

NO LOAD CURRENT | FULL | LOAD CURRENT | STARTING CURRENT |

| TORQUE |

|

|

ARMATURE CURRENT

Figure 3

Aside from the constant horsepower characteristics described above, there are many other features that provide increased performance and lower cost. The

January 2000