DesignJet 5000 and 5500 Series

Large-Format Printers

Safety Symbols

DesignJet 5000 and 5500 Series

Readership Part Numbers

Using this Manual

Purpose

Conventions

Table of Contents

Table of Contents

Troubleshooting

Introduction

Guide to Troubleshooting the Printer

Troubleshooting System Error Codes

Phone Support

Troubleshooting Calibration Error Codes

Performing a Service Test on a Failed Assembly

Performing the Necessary Service Calibrations

Solving Image Quality Problems

Troubleshooting Ink Supplies Error Codes

Troubleshooting Initialization Self Diagnostic Errors

Printer does not Power on

Status LED’s

When clearing a media jam, sometimes media is stuck

Troubleshooting Media Jams/Printhead Crashes

If using HP Coated Media when problem occurred, please also

ALL the Front-Panel LEDs are Lit but Nothing Else Happens

Attempting any procedures to resolve the problem

Troubleshooting Shutdowns User Message

Each case, make sure that you power OFF the Printer before

Check Printhead Cleaner Path

Check Paper Path

Check Printhead Path

Replace Message xx15 Replace and xx16 Replace

Problems with Vacuum

Vacuum suction much lower at high altitudes

Color differences in different HP DesignJet Printers

Banding with unsupported Media

Banding due to Ink Cartridge replacement while printing

Banding at variable extreme environmental conditions

Hue shift on HP Colorfast Adhesive Vinyl media

Black Smearing on HP Photo Imaging Gloss

Dry Cockle on High Density Prints Using Paper Based Media

Worm marks cockle on part of plots on paper based media

User message Media loaded incorrectly. Remove media

Media Skew when Printing a Banner Plot

Drying Time Too Long for HP Studio Canvas

User message Power Supply Error #1

User message Warning Incorrect type of tubes system

Page

Cutter Assembly Problems

This problem is solved in any A.02.xx firmware release

Carriage and Scan-Axis Problems

Media-Axis Problems

Electronics Problems

Setting while the Printer is in the stand-by mode might be

Network configuration

Temperature reading to adjust the printing speed. This is

Configuration 192Mbyte for C6096A and 128Mbytes for

Language Selection is blocked in a brand new printer

Firmware Upgrade Does Not Work Through the Parallel Port

This problem is solved in any A.02.xx firmware release

Dry time at the end of the print is longer

Typical Failures After Exchanging the Ink Tubes

Solving Media-Handling Problems

How to Navigate through the Front Panel Menus

Setup Menu

Setup

Utilities Menu

Short, Full

Internal RIP Settings Menu

DIC

Queuing and Nesting Menu

HP-GL/2 Settings Menu

Format Menu

ISO

Demos Menu

Roll/Sheet Info Vendor Name

Ink Cartridge Menu

Ink Level Capacity Part Number Manufacture Date Yes, No

Printhead Menu

Press Enter

Service Configuration Print

Printer Setup Options

How to Use the Service Configuration Print

Press Up and Enter

Lower

General Printer Information

These are maximum mechanical printing speeds and do not

Troubleshooting Take-Up-Reel Problems

Issue Main Reason Action/Check

System Error Codes

System Error Codes

System Error Codes

XXXXXX-YYYYZZZZ

To troubleshoot the problem

Continuable and Non-Continuable Error Codes

System Error Groups

Even though the customer can continue working with a

Ffff ffff 02b301b0

There is a problem with the I/O Card happens during power-up

Ffff ffff 01dcxxxx

01002D Non-Continuable

Ffff ffff

Ffff ffff 036e0136

System Error 010023 Non-Continuable

Different power socket

010041

ProblemError in Paper-axis Motor Encoder

040000 01E603D9

06030C

Bad Line Sensor

System Error Problem Description Corrective Action

Try the following

Problem in Depressurizing Air System

0A0030

0A0050 Non-Continuable

0A0070 Continuable

0B0001

System Error Problem Description Corrective Action

Unable to detect Fan X = 7 Vacuum, 8 Cooling, 9 Aerosol

Primer Shutdown Error

0B000X

0B0010 xxxxxxxx Non-Continuable

System Error Problem Description Corrective Action

0B000F Continuable Only applicable to DesignJet 5500 Series

System Error 0C0032 Continuable

XX21 Replace

0C1000

0D0003 xxxxxxxx Non-Continuable

0D0000 Continuable

0D0000 033f019C

0D0004 xxxxxxxx Non-Continuable

0D0005 03180382 Non-Continuable

Firmware Error has occurred

Refer to System Error Code ffff ffff

0FXXXX Non-Continuable

0F0200 01E603d2

0F0100 03180382 Non-Continuable

E50000

HP Ink Supplies Troubleshooting

Ink Cartridges

Printheads and Printhead Cleaners

What are HP Ink Supplies?

Identifying the Components

General Information About HP Ink Supplies

Some General Precautions When Handling HP Ink Supplies

Priming a Brand New Ink System

When Should You Replace the HP Ink Supplies?

Show the XX11Replace message Refer to 3-12, Error Status

Front Panel Display

Obtaining Ink Cartridge Information

Obtaining Printhead Information

Page

Simply following the instructions in the action message

Most problems with Ink Supplies will be solved by the user

Status Codes and Messages

Status Messages

Insert

Error Status Messages

Status Code Part / Information

Printhead Errors

Printhead Information

Printhead Recovery Procedure

Ink Cartridge Errors

Ink Cartridge Information

Ensure that you have the correct Printhead Cleaner

Printhead Cleaner Errors First Digit = A, B or

When replacing Printhead Cleaners

Ensure that the Printhead Cleaner is the correct color for

Ink Cartridge Delivers Too Much Ink

Refill Information DesignJet 5500 Series Only

Ink-Level Sensing ILS Out of Control

Risks with the Ink Cartridge Delivering Too Much Ink

Non-HP Hardware Detected in the Ink Delivery System

1RQ+3KDUGZDUH Lvghwhfwhg

Risks with Using Non-HP Hardware

ILS Out of Control Detection

ILS Out of Control Warranty Statement

HP Ink Supplies Troubleshooting

Service Tests Utilities

Diagnostics Self Test

Introduction

Self Diagnostics Initialization Sequence

Service Tests and Utilities

Present after replacing a component, remember to Reinstall

Component that was first removed before replacing another

Component

Service Tests Diagnostics

Entering the Service Tests Menu

Press Down Enter Together

Top

Scan Axis Test

Report the values to the nearest HP Response Center or HP

Support Office to determine whether values are within

Media Axis Test

With Media

Service Utilities

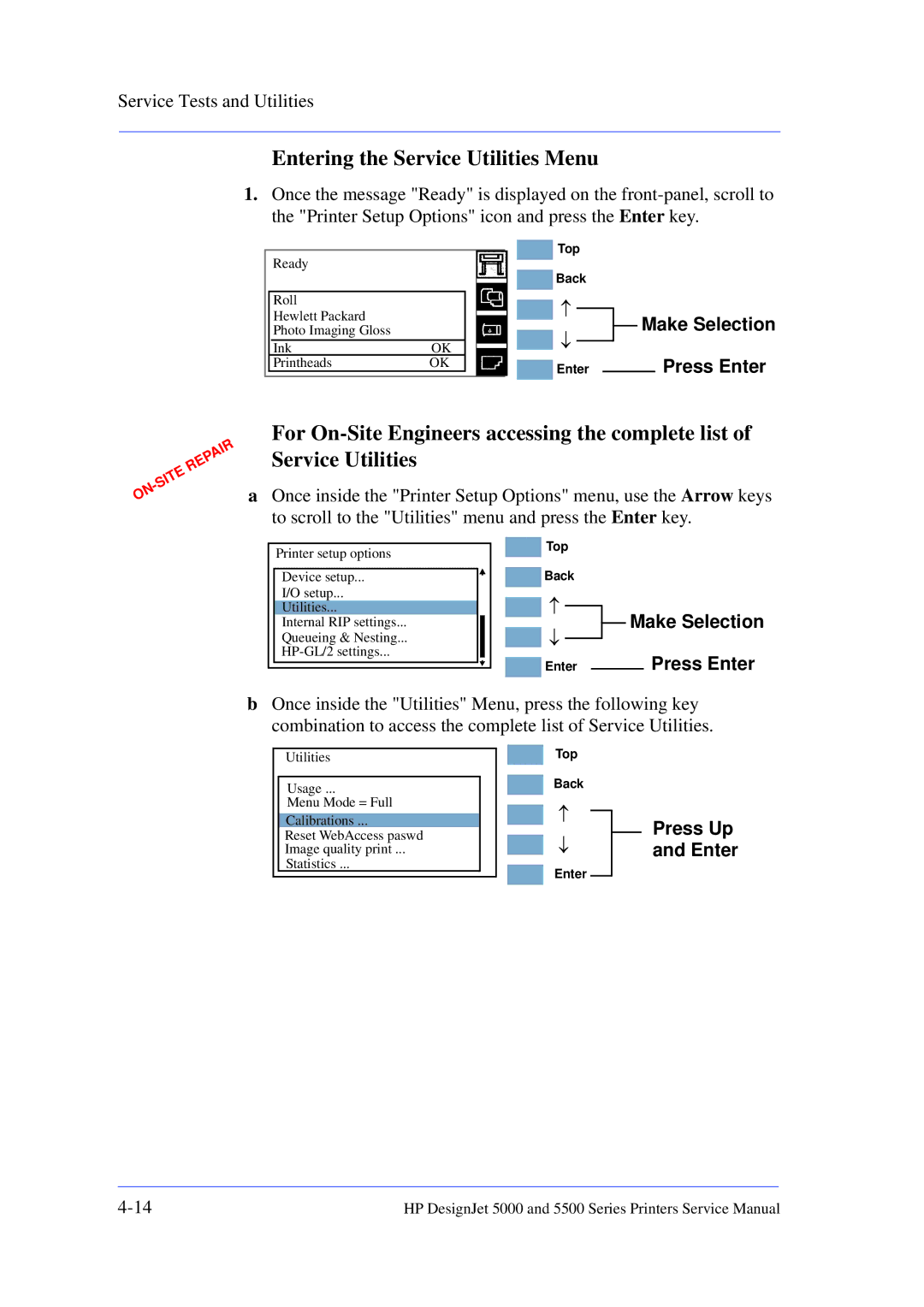

Entering the Service Utilities Menu

Press Down and Enter

Service Tests and Utilities

Turn Drive Roller

Detected, the message below is displayed

Prime Tubes

Ink

Initializing printer Please wait. xx sec

INK Startup

Altitude Setup

Over 2000 m

Eerom Setup

All the Eerom parameters

If you want to set the Model Number

If you want to set the Serial Number

Encoded in the Eerom

If you want to set the Japanese Fonts

Press Back

Make Selection

Reset Life Counters

Counter for a component when it has not been replaced

Back Press Back

Backup Eerom

Series Only

Press Back to return to the Service Utilities menu

That color

Image Quality Warning

If you use degraded Printheads, the print quality may be

You need

Diagnostic Print

Printer does not print the complete Diagnostic Print

Enter to print it

Sleep Mode DesignJet 5500 Series Only

Service Calibrations

Refer to the following page for the relevant Calibration

Service Calibrations

Entering the Service Calibrations Menu

Press Up Enter Together

Press Down Enter Together

Service Calibrations

Scan-Axis Calibration

That is the full width of the Printer

Use the ID 00 and for the 5500 Series use the ID

Make Selection

Can be located on the label on the side of the Line Sensor

If Scan Axis Calibration is performed without inserting

Correct Line Sensor Id., each time the user performs a Color

After the Calibration has been performed, print the Service

Refer to page 5-26, Calibration Error Codes to troubleshoot

Error codes

EEROM. For information on the Service Config Print Ÿ

Service Station Calibration

Service Station Press Enter to confirm or Back to correct

Press Back

Perform the Accuracy Calibration as follows

Codes for its description and resolution

Accuracy Calibration

Media apart from HP High Gloss Photo Paper

Do not use any other type of media apart from HP High Gloss

Photo Paper

Press Load/Unload Media

Codes

Carriage Height Calibration

Procedure should be carried out using the Carriage Height

Assembly or Center Platen Assembly

Tool See below that came with the new Carriage

Service Calibrations

With the Carriage itself See below

Page

Screws should not be removed

Page

Page

Page

Page

Calibration Error Codes Introduction

Line Sensor error

This code is not an error. See the other codes reported

Pen voltage error

0000

User

Power the Printer OFF and on using the power switch at

Paper Axis Error

Light Magenta Pattern

Media Profile Error

Service Calibrations

Firmware Error

3130

Out of memory

Service

Service, 4006 Service and 4007 Service

Black Printhead failure

Could not detect pattern

Service and 5012 Service

Drop Detector not working

Drop Detector failed to uncap pens Refer to Error Code

Calibration failed for Light Cyan Printhead

Service

User Calibrations

Printhead Alignment

Close-Loop-Color CLC Calibration

Banding Calibration

Their original media advance settings

Accuracy Calibration applies only to the media type

Service Calibrations

Print Quality

Print Quality Troubleshooting Checklist

Print Quality

Photo Paper when performing the Service Accuracy

Calibration

Considerations for Printing the Diagnostic Print

How to Use the Diagnostic Print

What is the Diagnostic Print?

Printing the Diagnostic Print

Press Down and Enter

For Firmware Version A.02.xx in the 5000 Series and on

Series, the Printer does not print the complete Diagnostic

Print Quality

That you need

Overall Print Quality Test

What is Banding?

Solving the Banding Problem

Productivity and Max. Speed modes. If you use Max. Quality

Printer has automatic procedures to hide many Printhead

Defects. This type of problem affects print quality mostly

Be hidden and image quality may not be affected

High quality modes media advance problems may not appear

Or graininess will appear in all the colors

Solving the Color Alignment Problem

Color Alignment Print Test

Solving Bidirectional Alignment Problems

Bidirectional Alignment

Vertical Line Straightness

Solving Vertical Line Straightness

Modes

Nozzle Print Test

Affects print quality mostly in Productivity and Max. Speed

How to fix the Nozzle Defects

No Printing Defects Found in the Diagnostic Print

Print Quality Problems

Solving Color Accuracy problems

Solving Color Consistency problems

Prints are Too Short DesignJet 5000 Series Only

Color Accuracy Configuration

Blurred Lines Ink Bleeds from Lines

Colors are not as Expected

Banding at the Top

Printed surface smearing roll DesignJet 5000 Series Only

Vertical Banding

Media

There are Smears or Scratching on the Printed Media

Warped Lines on Media

Marks and/or scratches on double-sided media

Objective and Description

Using the Color Print

How to Evaluate the Print

How to Interpret the Result

Enrichment Issue

Issues Description

Cause

Page

Workarounds

Problem statement

Ink Marks on Printouts

Cause 1 Aerosol Aerosol Background

Aerosol What customers see

WKH3ULQWRXW

Which printers are affected by this?

What can you see?

Ink accumulation at the bottom edges of the Printheads

See the following image to for an example

Ink accumulation at the bottom of the Carriage Assembly

This is a secondary effect of the ink accumulation

Static Solutions and Workarounds

Parts and Diagrams

Printer Support

Printer Support

Bin and Take-Up Reel

Series

Bin Support

Bin and Take-Up Reel

Right Hand Cover

Right Hand Cover

HP Part Number Quantity Description/Comments Drawing

Left Hand Cover and Rear Door

OEM Logos

Left Hand Cover and Rear Door

Top and Back Covers

Top and Back Covers

Service Station

Service Station

Vacuum Fan

Vacuum Fan

Booster Fan and Media Sensor

Booster Fan and Media Sensor

Paper-Axis Motor

Paper-Axis Motor

Scan-Axis Motor

Scan-Axis Motor

ISS and APS Assembly

ISS and APS Assembly

Ink Tubes System

Ink Tubes System

Boot ROM DIMM, Dram Memory and Covers

OEM Boot ROM Dimm

BootROM, Memory and Covers

Rear Electronics Access Covers

Rear Electronics Access Covers

Hard Disk Drive and Cover

OEM Hard Disk Drive

Hard Disk Drive and Cover

ISS PCA and Main PCA

ISS PCA and Main PCA

Power Supply Unit

Power Supply Unit

Carriage Assembly

Carriage Assembly

Tensioner Assembly and Encoder Strip

Tensioner Assembly and Encoder Strip

Platen Assemblies DesignJet 5000 Series

Series Only

Platen Assemblies DesignJet 5000 Series

Platen Assemblies DesignJet 5500 Series

Platen Assemblies DesignJet 5500 Series

Pinch-Wheels Assembly and Lever

Pinch-Wheels Assembly and Lever

Center Guide 60 Model

Parts and Diagrams

Center Guide and Entry Roller DesignJet 5500 Series

Center Guide and Entry Roller DesignJet 5500 Series

Tubes Guide Assemblies

Tubes Guide Assemblies

EMC Covers

EMC Covers

Spindle and Hub

Spindle and Hub

Rollfeed Brakes

Rollfeed Brakes

Miscellaneous Items

Media Types

Parts and Diagrams

Removal and Installation

Safety Precautions

Electrostatic Discharge ESD Precautions

Required Tools

Chassis screws have a copper washer and should never be

Removed

Top Cover Assembly

Removal

Printer

Switch off the Printer and remove the power cable

Remove ALL the Ink Cartridges from

Page

Page

When inserting the Left Hand Cover, be careful not to pinch

Installation of Left Hand Cover

When handling the Tubes make sure you do not damage them by

Twisting

Right Hand Cover

P24

Page

Page

Installation of Right Hand Cover

Front Panel Assembly

Switch off the Printer and remove the Power Cord

Left Rear Cover

Right Rear Cover

Remove 4 T-15 screws Type B from

Extension Cover 60 Model only

Remove the Left Rear Cover Refer

Extension Cover

Media Lever Assembly

Spring in the Trim

Installation of the Media Lever Assembly

Sideplate in the UP position to avoid damaging the Lever

Right Hand Trim

P27

Lever in the UP position to avoid damaging the Lever spring

Installation of Right Hand Trim

When installing the Media Lever in the Trim, install with

Trim

Left Hand Trim

Back Cover

Number onto it

Installation of the Back Cover

Label has been applied, copy the product number and serial

Out the Printhead Cleaner Carriage

Open the Right Cover door and pull

Page

Page

Page

Page

Installation of Ink Tubes System

Perform the following procedures

INK Startup Initializing Printer Please wait 60 sec

EMC Covers

Lower Right Cover

Encoder Strip

Release Encoder Strip

Below

Installation of Encoder Strip

When Installing the Encoder Strip, make sure it is placed

Trailing Cable

Slide out

Ferrites if they fall into Carriage

When disconnecting from Main PCA

Guide to access the screw

Installation of Trailing Cable

Check edge for damage

Trailing Cables through Ferrites

Right Clip Slot Locating pin

Is flat on the chassis without

Removal and Installation

Make sure the Trailing Cable

Bubbles

Tensioner Assembly

Tighten screw

Page

Installation of Tensioner Assembly

Carriage Assembly and Belt

Page

Page

Page

Slide out

Page

Installation of Carriage and Belt

Line Sensor

Page

Installation

3XVKKHUH

Scan-Axis Motor

P23

Encoder Sensor on the rear of the Carriage Assembly

Installation of the Scan-Axis Motor

When installing the Encoder Strip, make sure it is inserted

Slider Rods Lubrification Kit Refer to

Cutter Assembly

Open the Top Cover

Page

Page

Page

Ink Supply Station ISS

Inside View Front

Installation of ISS

Switch off the Printer and remove the Power Cord

Air Pressurization System APS

Following steps

Installation of APS

When Installing the Air Pressurization System make sure

Remove the Right Rear Cover Refer

Service Station Assembly

Remove the Printhead Cleaners

P15

Page

Drop Detector Assembly

Press clip to disconnect

Move the Drop Detector

Hard Disk Drive HDD

Installation of Hard Disk Drive

If you have to replace HDD Cable, refer to the following

LAN Card

Memory and BootROM DIMM’s

Modules

Installation of DIMM’s

Position as shown in the diagram

Electronics Module Cover

They pass through the slot in the Cover

Installation of the Electronics Module Cover

When Installing the Electronics Module Cover make sure

Main PCA

Remove the Electronics Module

Page

Installation of Main PCA

PCI-to-IDE PCA

P11 Connector on the Main PCA even if the P11

Installation of the PCI-to-IDE PCA

When installing the new PCI-to-IDE PCA, Connect

Connector is present and the HDD Power Cable was connected

Installing the HDD Cable

Power Supply Unit PSU

PCA PS Connector

Press PS Fans PS Switch PS Socket

Power Supply Unit connections are illustrated below

Installation of the Power Supply Unit PSU

After installing the Power Supply Unit, remember to place

Plastic protective cover over the unit

Ink Supply Station ISS PCA

Installation of the ISS PCA

J3 P3

Removal

Remove the Ink Leak Detector from the Printer

Cooling Fans

Page

Electronics Module as one complete Assembly

Pinch-Wheels

Wheels at each end of the Printer axis

Installation of Pinch-Wheels

During installation, make sure you install the White Pinch

Pinch-Wheel Cam

Page

Installation of Cam

Vacuum Fan

P19

Installation of Vacuum Fan

Guides in the Sideplate

Paper-Axis Motor Assembly

P10 P12

106

Apply grease to the Helical Gear

Installation of Paper-Axis Motor Assembly

Screws are tight

Booster Fan

Media Sensor

Shown in the diagram

Installation of Media Sensor

When installing the Media Sensor, insert the moving part as

Entry Roller

Center Guide Assembly

Page

Remove the Drive Roller Gear

Installation of Gear

Drive Roller Gear

Fully tightened

Front Platen Assembly Only Applicable to the 5000 Series

Remove the Left Hand Trim Refer to

116

Center Platen Assembly

Removing the Platen Assembly

Installation of the Center Platen Assembly

Deflectors Only Applicable to the 5000 Series

Disconnect the Heater Cable from

Heater Assembly Only Applicable to the 5500 Series

Remove the Right Cover Refer to

Page

122

Installing the Heater

Tube Guide Door

Preventive Maintenance

Utilities/Service Configuration Print

Service Preventive Maintenance

Maintenance information can be obtained from Printer Setup

Ink Tube Maintenance Advised

Have Ink Tube Replaced or Risk Printer Damage

Ink Tube Maintenance Required Now

If Printing is , the Tubes can break causing a

Contact HP

User Maintenance

Lens Maintenance

Do not handle or attempt to clean the Nozzles on the bottom

Printhead

Roller Lubrification Kit

This procedure is for Service Engineers only. Users should

Perform the procedure described in the User’s Guide

Avoid oil spills and make sure you remove any excess oil

Power Off the Printer and remove the Power Cord

Slider Rods Lubrification Kit

Cleaning the Platen

Preventive Maintenance

Noisy Carriage Bushing

General Cleaning

Moisture on the Printer

Belt Swelling

Firmware Upgrade

Button and look for Programs HP DesienJet folder and run it

Upgrade Instructions 5000 Series only

Upgrade process may take several minutes. Do not Power

From there

Functional Overview

Electrical System

Front Panel

Scan Axis

Paper Axis

Ink Delivery System IDS

Ink Cartridge

Ink Supply Station ISS

Tubes System

Printheads

Air Pressurization System APS

Service Station

Print Head Cleaner PHC

10-10

About this Edition

DesignJet 5000 and 5500 Series