Disassembly and Cleaning

5

5.3Maintenance and Inspection

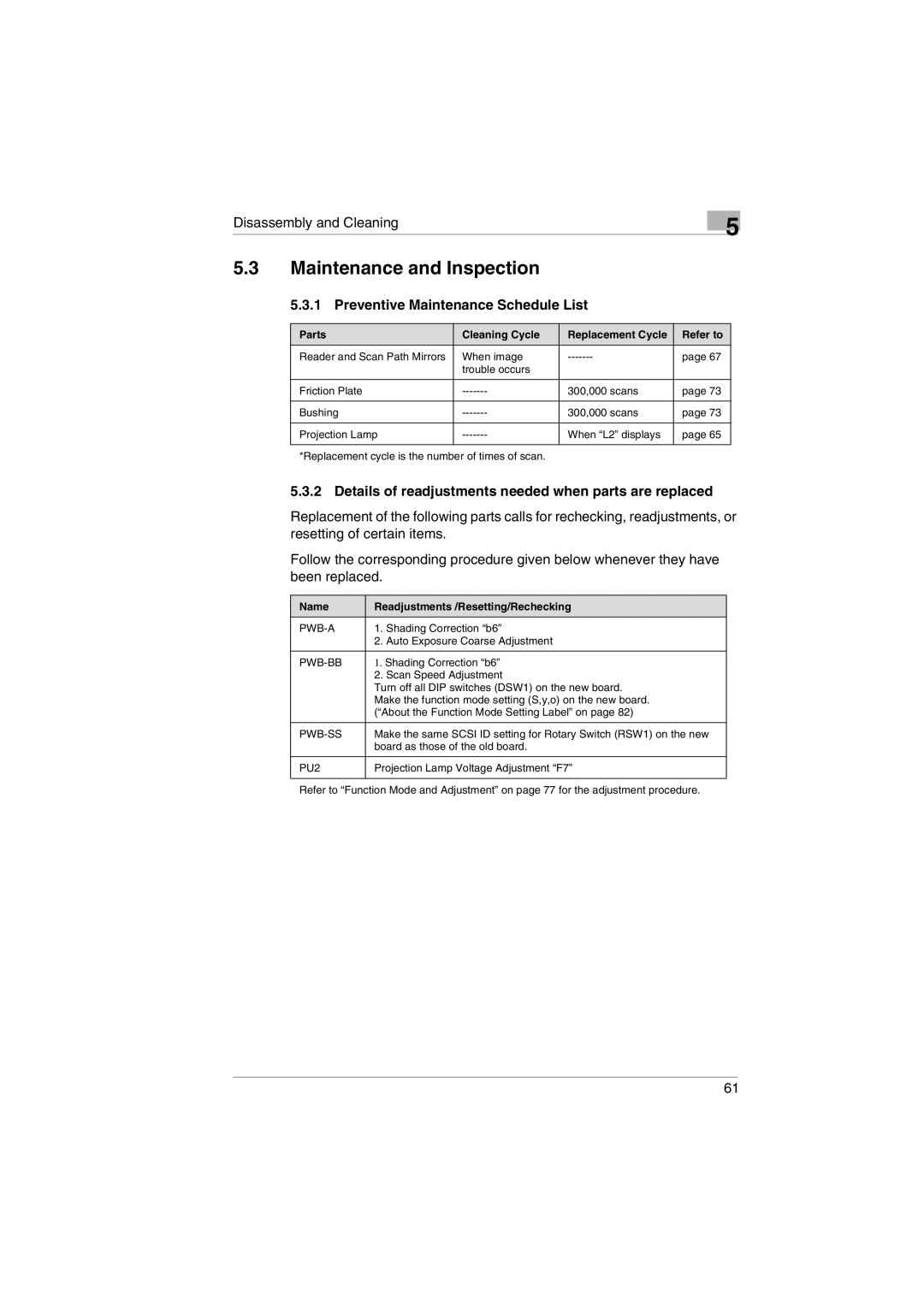

5.3.1 Preventive Maintenance Schedule List

Parts | Cleaning Cycle | Replacement Cycle | Refer to |

Reader and Scan Path Mirrors | When image | page 67 | |

| trouble occurs |

|

|

|

|

|

|

Friction Plate | 300,000 scans | page 73 | |

|

|

|

|

Bushing | 300,000 scans | page 73 | |

|

|

|

|

Projection Lamp | When “L2” displays | page 65 | |

|

|

|

|

*Replacement cycle is the number of times of scan.

5.3.2 Details of readjustments needed when parts are replaced

Replacement of the following parts calls for rechecking, readjustments, or resetting of certain items.

Follow the corresponding procedure given below whenever they have been replaced.

Name | Readjustments /Resetting/Rechecking |

1. Shading Correction “b6” | |

| 2. Auto Exposure Coarse Adjustment |

|

|

1. Shading Correction “b6” | |

| 2. Scan Speed Adjustment |

| Turn off all DIP switches (DSW1) on the new board. |

| Make the function mode setting (S,y,o) on the new board. |

| (“About the Function Mode Setting Label” on page 82) |

|

|

Make the same SCSI ID setting for Rotary Switch (RSW1) on the new | |

| board as those of the old board. |

|

|

PU2 | Projection Lamp Voltage Adjustment “F7” |

|

|

Refer to “Function Mode and Adjustment” on page 77 for the adjustment procedure.

61