4026-0XX

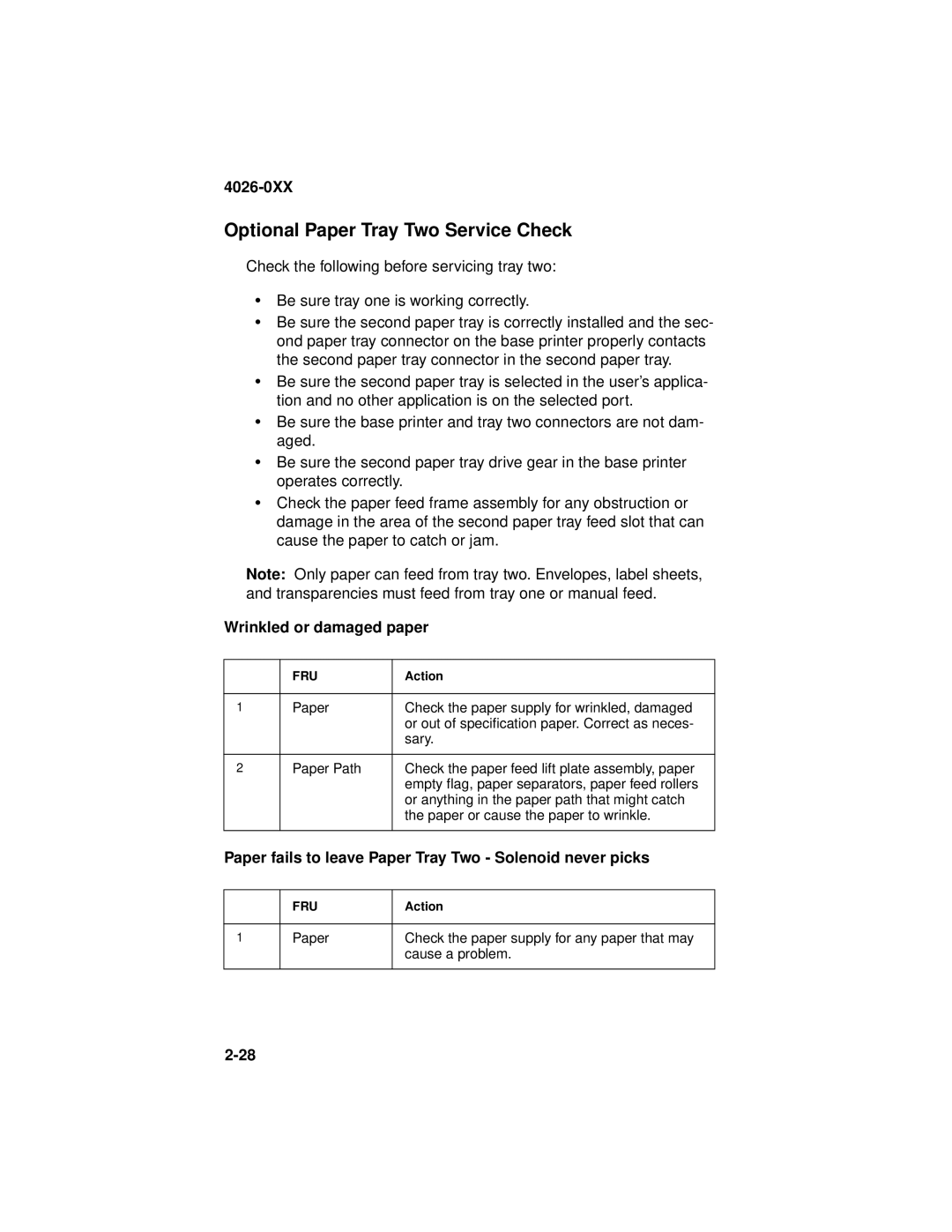

Optional Paper Tray Two Service Check

Check the following before servicing tray two:

•Be sure tray one is working correctly.

•Be sure the second paper tray is correctly installed and the sec- ond paper tray connector on the base printer properly contacts the second paper tray connector in the second paper tray.

•Be sure the second paper tray is selected in the user’s applica- tion and no other application is on the selected port.

•Be sure the base printer and tray two connectors are not dam- aged.

•Be sure the second paper tray drive gear in the base printer operates correctly.

•Check the paper feed frame assembly for any obstruction or damage in the area of the second paper tray feed slot that can cause the paper to catch or jam.

Note: Only paper can feed from tray two. Envelopes, label sheets, and transparencies must feed from tray one or manual feed.

Wrinkled or damaged paper

| FRU | Action |

|

|

|

1 | Paper | Check the paper supply for wrinkled, damaged |

|

| or out of specification paper. Correct as neces- |

|

| sary. |

|

|

|

2 | Paper Path | Check the paper feed lift plate assembly, paper |

|

| empty flag, paper separators, paper feed rollers |

|

| or anything in the paper path that might catch |

|

| the paper or cause the paper to wrinkle. |

|

|

|

Paper fails to leave Paper Tray Two - Solenoid never picks | ||

|

|

|

| FRU | Action |

|

|

|

1 | Paper | Check the paper supply for any paper that may |

|

| cause a problem. |

|

|

|