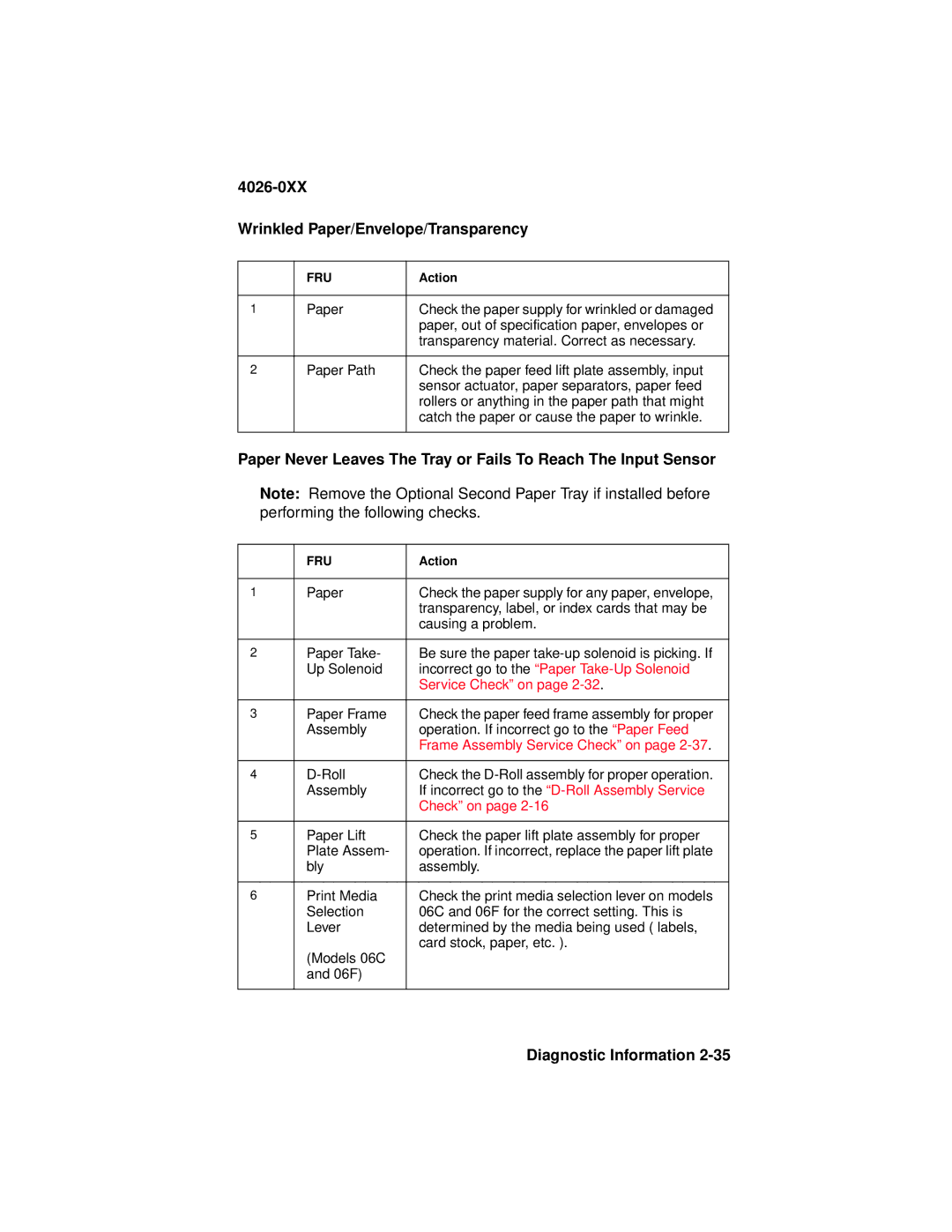

4026-0XX

Wrinkled Paper/Envelope/Transparency

| FRU | Action |

|

|

|

1 | Paper | Check the paper supply for wrinkled or damaged |

|

| paper, out of specification paper, envelopes or |

|

| transparency material. Correct as necessary. |

|

|

|

2 | Paper Path | Check the paper feed lift plate assembly, input |

|

| sensor actuator, paper separators, paper feed |

|

| rollers or anything in the paper path that might |

|

| catch the paper or cause the paper to wrinkle. |

|

|

|

Paper Never Leaves The Tray or Fails To Reach The Input Sensor

Note: Remove the Optional Second Paper Tray if installed before performing the following checks.

| FRU | Action |

|

|

|

1 | Paper | Check the paper supply for any paper, envelope, |

|

| transparency, label, or index cards that may be |

|

| causing a problem. |

|

|

|

2 | Paper Take- | Be sure the paper |

| Up Solenoid | incorrect go to the “Paper |

|

| Service Check” on page |

|

|

|

3 | Paper Frame | Check the paper feed frame assembly for proper |

| Assembly | operation. If incorrect go to the “Paper Feed |

|

| Frame Assembly Service Check” on page |

|

|

|

4 | Check the | |

| Assembly | If incorrect go to the |

|

| Check” on page |

|

|

|

5 | Paper Lift | Check the paper lift plate assembly for proper |

| Plate Assem- | operation. If incorrect, replace the paper lift plate |

| bly | assembly. |

|

|

|

6 | Print Media | Check the print media selection lever on models |

| Selection | 06C and 06F for the correct setting. This is |

| Lever | determined by the media being used ( labels, |

| (Models 06C | card stock, paper, etc. ). |

|

| |

| and 06F) |

|

|

|

|