Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

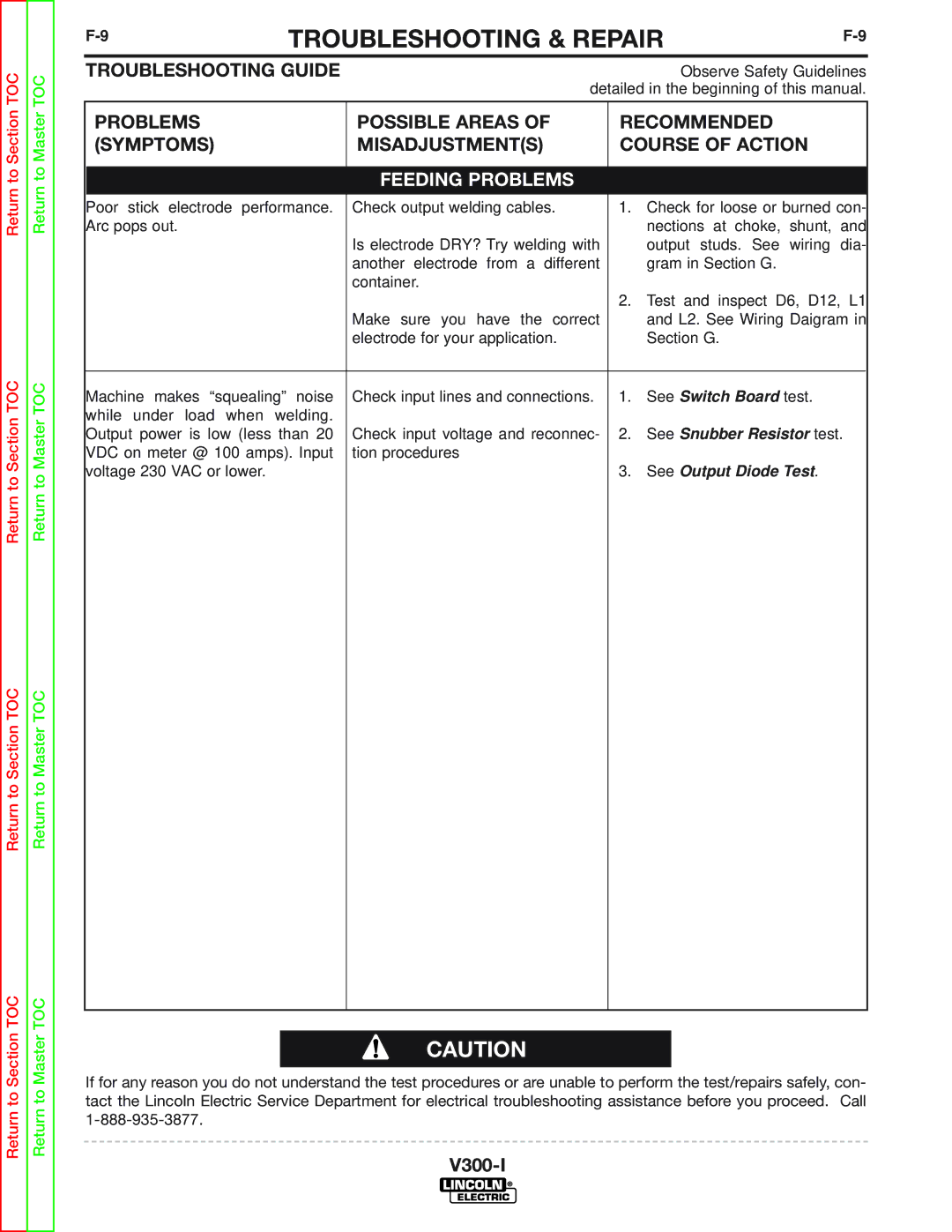

TROUBLESHOOTING & REPAIR | |||||

TROUBLESHOOTING GUIDE |

|

| Observe Safety Guidelines | ||

|

| detailed in the beginning of this manual. | |||

|

|

|

|

| |

PROBLEMS |

| POSSIBLE AREAS OF | RECOMMENDED |

| |

(SYMPTOMS) |

| MISADJUSTMENT(S) | COURSE OF ACTION |

| |

|

|

|

|

|

|

|

| FEEDING PROBLEMS |

|

|

|

Poor stick electrode performance. | Check output welding cables. | 1. | Check for loose or burned con- | ||

Arc pops out. |

|

|

| nections at choke, shunt, and | |

|

| Is electrode DRY? Try welding with |

| output studs. See wiring dia- | |

|

| another electrode from a different |

| gram in Section G. |

|

|

| container. |

|

|

|

|

|

| 2. | Test and inspect D6, D12, L1 | |

|

| Make sure you have the correct |

| and L2. See Wiring Daigram in | |

|

| electrode for your application. |

| Section G. |

|

|

|

|

|

|

|

Machine makes “squealing” | noise | Check input lines and connections. | 1. | See Switch Board test. |

|

while under load when welding. |

|

|

|

| |

Output power is low (less than 20 | Check input voltage and reconnec- | 2. | See Snubber Resistor test. |

| |

VDC on meter @ 100 amps). Input | tion procedures |

|

|

| |

voltage 230 VAC or lower. |

|

| 3. | See Output Diode Test. |

|

|

|

|

|

|

|

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, con- tact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call