TOC

TOC

A-3 INSTALLATIONA-3

PRODUCT DESCRIPTION

ELECTRICAL INSTALLATION

The Invertec

![]() WARNING

WARNING

1.The Invertec should be connected only by a quali- fied electrician. Installation should be made in accordance with the U.S. National Electrical Code, all local codes and the information detailed below.

2.When received from the factory, multiple voltage

Return to Section TOC

TOC

Return to Master TOC

TOC

ELECTRIC SHOCK can kill.

•Have an electrician install and ser- vice this equipment.

•Turn the input power off at the fuse box before working on equipment.

•Do not touch electrically hot parts.

LOCATION

The Invertec has been designed with many features to protect it from harsh environments. Even so, it is important that simple preventative measures are fol- lowed in order to assure long life and reliable opera- tion.

•The machine must be located where there is free cir- culation of clean air such that air movement into the sides and out the bottom and front will not be restricted. Dirt and dust that can be drawn into the machine should be kept to a minimum. Failure to observe these precautions can result in excessive operating temperatures and nuisance shutdown of the Invertec.

3.Single voltage, 575 VAC machines, can only be connected to 575 VAC. No internal reconnection for other input voltages is possible.

4.Initial 208 VAC and 230 VAC operation will require

avoltage panel setup, as will later reconnection back to 460 VAC:

a.Open the access panel on the right side of the machine.

b.For 208 or 230: Position the large switch to

For 460: Position the large switch to

c.Move the “A” lead to the appropriate terminal.

CAUTION: DO NOT CHANGE SWITCH POSITION WITH INPUT POWER APPLIED. MAJOR DAMAGE WILL RESULT.

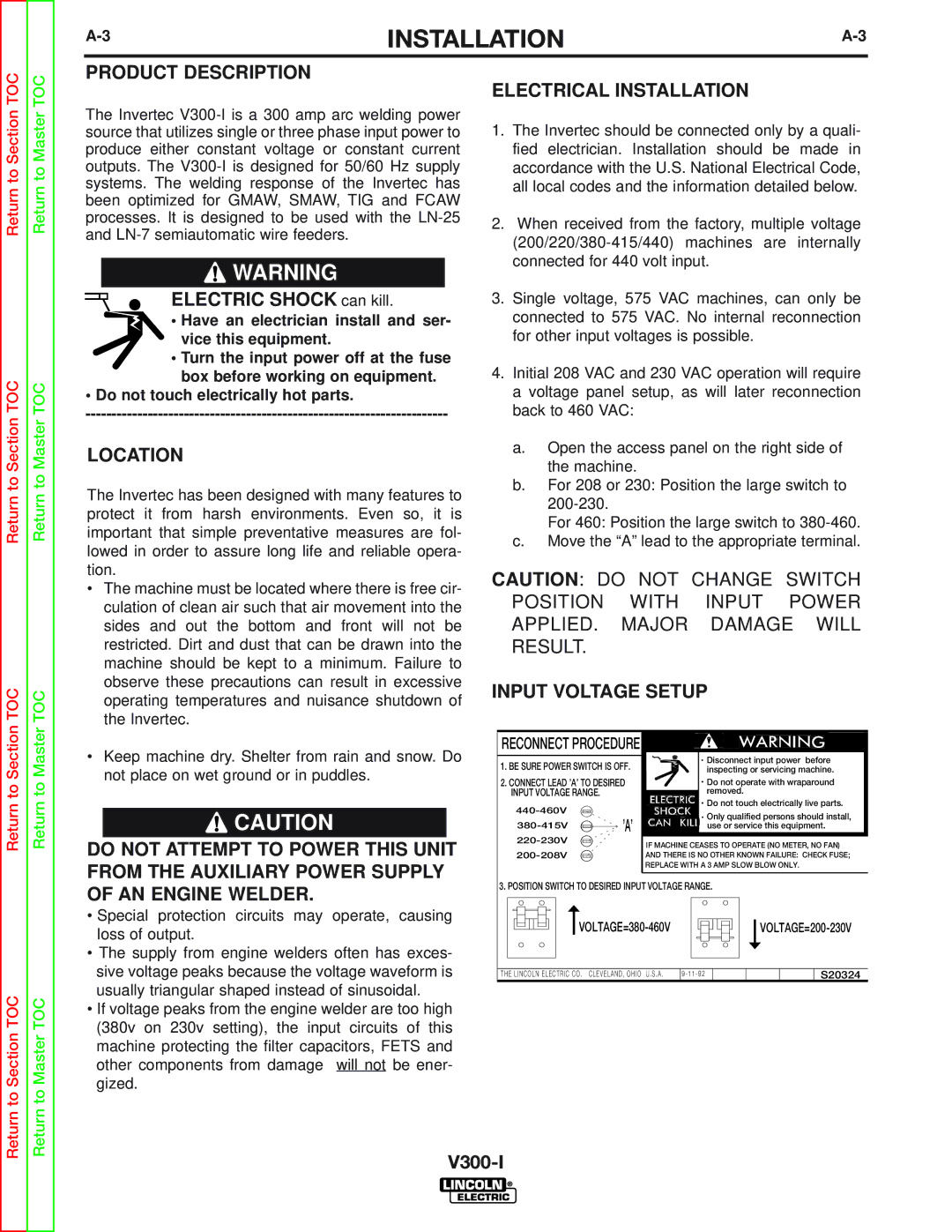

INPUT VOLTAGE SETUP

Return to Master

Return to Master TOC

•Keep machine dry. Shelter from rain and snow. Do not place on wet ground or in puddles.

![]() CAUTION

CAUTION

DO NOT ATTEMPT TO POWER THIS UNIT FROM THE AUXILIARY POWER SUPPLY OF AN ENGINE WELDER.

•Special protection circuits may operate, causing loss of output.

•The supply from engine welders often has exces- sive voltage peaks because the voltage waveform is usually triangular shaped instead of sinusoidal.

•If voltage peaks from the engine welder are too high (380v on 230v setting), the input circuits of this machine protecting the filter capacitors, FETS and other components from damage will not be ener- gized.

RECONNECT PROCEDURE |

1. BE SURE POWER SWITCH IS OFF. |

|

|

|

|

| . Disconnect input power before |

|

|

|

| |||

|

|

|

|

| inspecting or servicing machine. | |

|

|

|

|

|

2. CONNECT LEAD ’A’ TO DESIRED | . Do not operate with wraparound | |||

INPUT VOLTAGE RANGE. |

|

| removed. | |

| . Do not touch electrically live parts. | |||

| . | Only qualified persons should install, | ||

| ’A’ | |||

use or service this equipment. | ||||

| ||||

IF MACHINE CEASES TO OPERATE (NO METER, NO FAN) | |

| |

AND THERE IS NO OTHER KNOWN FAILURE: CHECK FUSE; | |

| REPLACE WITH A 3 AMP SLOW BLOW ONLY. |

3. POSITION SWITCH TO DESIRED INPUT VOLTAGE RANGE. |

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

THE LINCOLN ELECTRIC CO . CLEVELAND, OHIO U . S . A . | 9 - 11 - 92 |

|

|

|

|

|

| S20324 | |||