TOC

TOC

THEORY OF OPERATION | |||

|

|

|

|

|

| FIGURE |

|

Return to Section

to Section TOC

Return to Master

to Master TOC

| LINE | |

| SWITCH | |

1 |

| |

2 |

| |

3 | 3A | |

| ||

FAN | AUXILIARY | |

TRANSFORMER | ||

|

POWER SWITCH SECTIONS 20KHZ

LEFT SWITCH BOARD

FET MODULES

|

| CAP |

| |

|

| FET MODULES | CURRENT | |

1˘ OR 3˘ DETETCTION (H5) |

| |||

| TRANSFORMER | |||

|

|

| ||

|

|

| ||

INPUT | DRIVER |

|

| |

RECTIFIER | BOARD |

| CONTROL | |

| CR1 |

| ||

|

| BOARD | ||

AC1 |

| PROTECTION | ||

PULSE |

| |||

AC2 | BOARD | |||

TRAIN | ||||

AC3 |

|

| ||

CR2 |

|

| ||

|

|

| ||

|

|

| ||

24VDC |

|

| ||

|

|

| ||

|

| RIGHT SWITCH BOARD |

| |

18VAC | 2ND STEP PWM | FET MODULES |

| |

|

| |||

|

|

| ||

| POWERBOARD | CAP |

| |

24VAC |

|

| ||

|

|

| ||

|

| FET MODULES |

| |

|

| <1 VDC |

| |

MAIN | CHOKE | RECTIFIER | |

TRANSFORMER | |||

HEATSINK | |||

|

| ||

TOP |

|

| |

|

| 1 DIODE |

5 DIODES

BOTTOM

5 DIODES

TOP

1 DIODE

Return

Return

TO WIREFEEDER

|

|

|

| CHOKE |

LOCAL | METER | MODE POT | POT | VOLTAGE FEEDBACK |

REMOTE |

| |||

|

|

|

| |

1ST STEP PWM VOLTAGE |

| CURRENT | ||

CHOKE

SHUNT

TOC

TOC

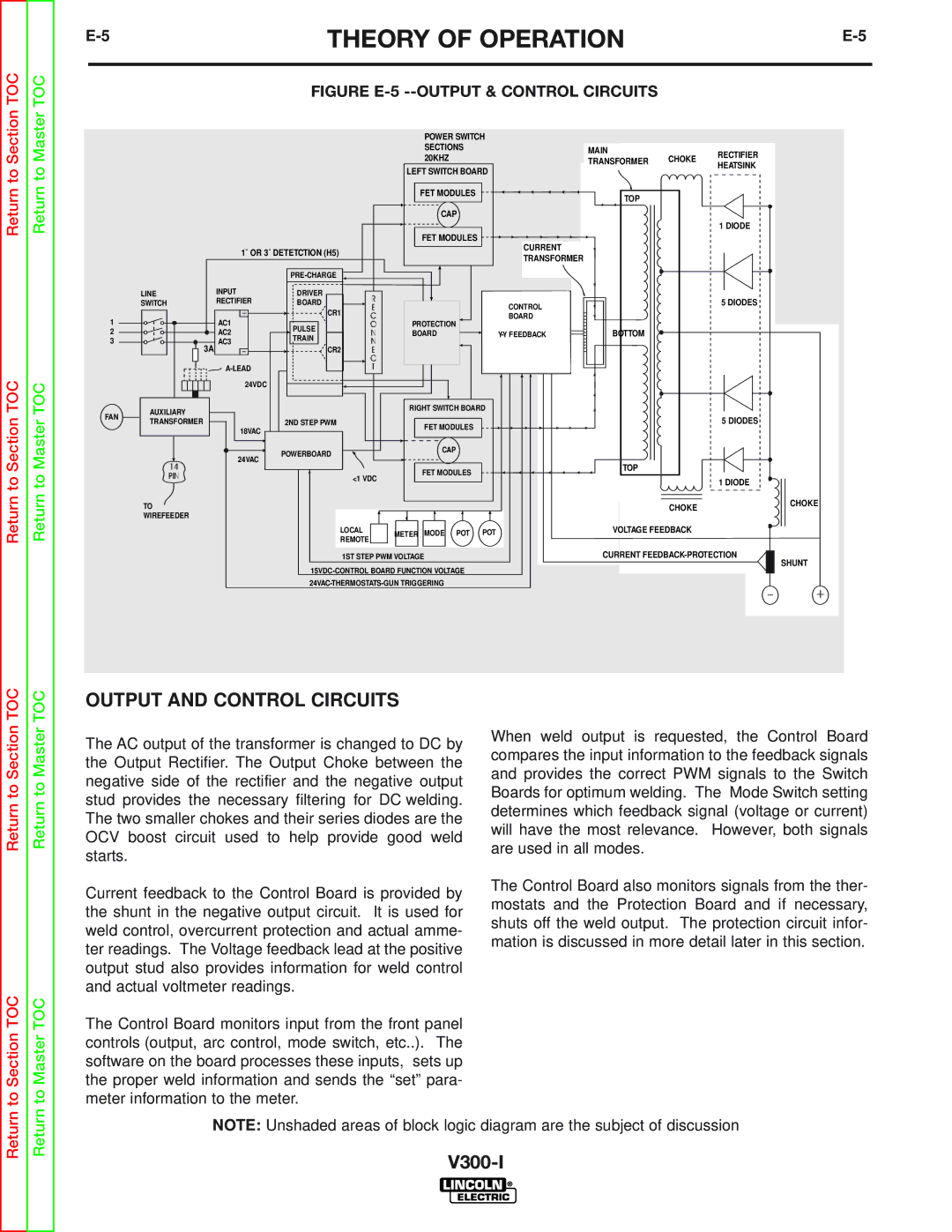

OUTPUT AND CONTROL CIRCUITS

Return to Section

to Section TOC

Return to Master

to Master TOC

The AC output of the transformer is changed to DC by the Output Rectifier. The Output Choke between the negative side of the rectifier and the negative output stud provides the necessary filtering for DC welding. The two smaller chokes and their series diodes are the OCV boost circuit used to help provide good weld starts.

Current feedback to the Control Board is provided by the shunt in the negative output circuit. It is used for weld control, overcurrent protection and actual amme- ter readings. The Voltage feedback lead at the positive output stud also provides information for weld control and actual voltmeter readings.

The Control Board monitors input from the front panel controls (output, arc control, mode switch, etc..). The software on the board processes these inputs, sets up the proper weld information and sends the “set” para- meter information to the meter.

When weld output is requested, the Control Board compares the input information to the feedback signals and provides the correct PWM signals to the Switch Boards for optimum welding. The Mode Switch setting determines which feedback signal (voltage or current) will have the most relevance. However, both signals are used in all modes.

The Control Board also monitors signals from the ther- mostats and the Protection Board and if necessary, shuts off the weld output. The protection circuit infor- mation is discussed in more detail later in this section.

Return

Return

NOTE: Unshaded areas of block logic diagram are the subject of discussion