Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

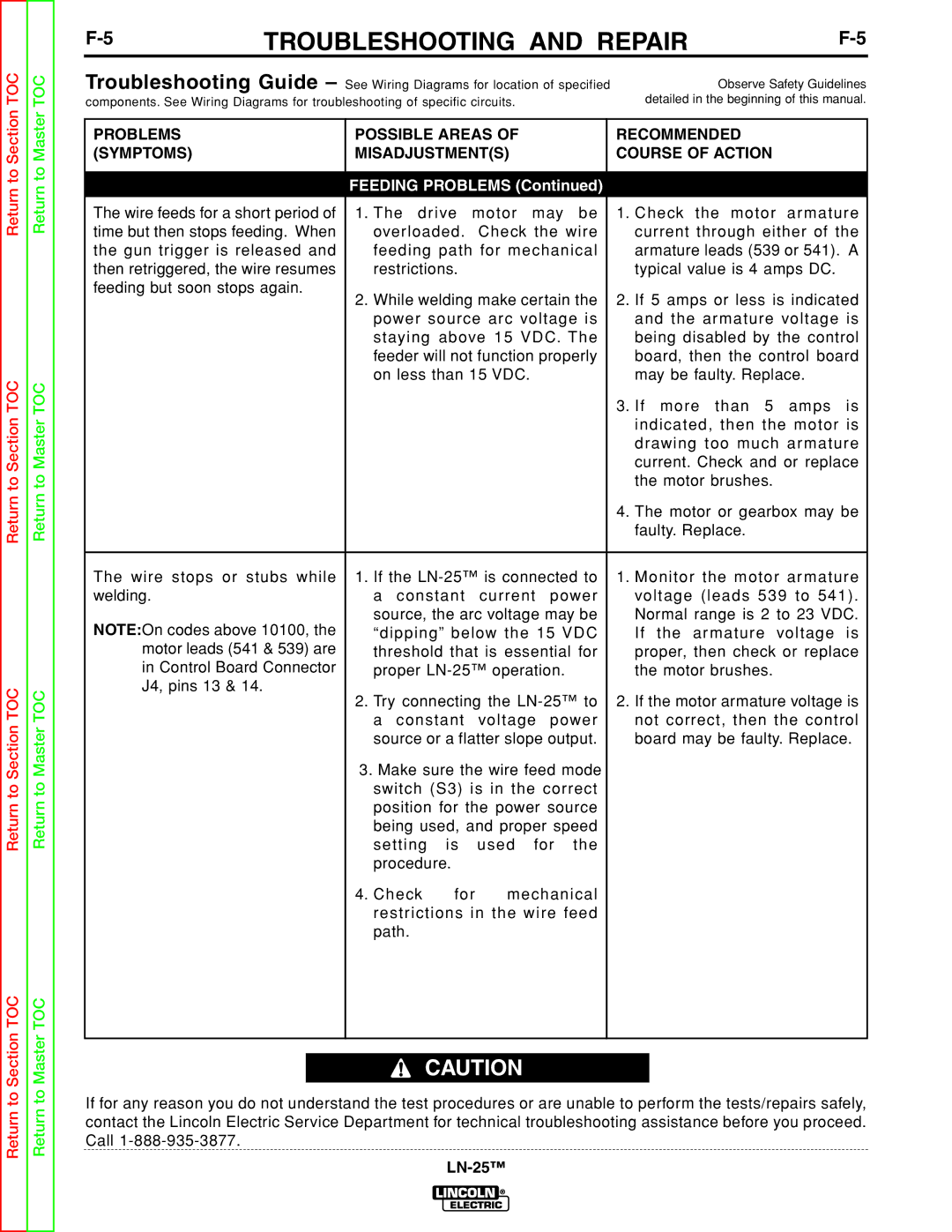

| TROUBLESHOOTING AND REPAIR | |||||||

|

|

|

|

|

|

|

|

|

Troubleshooting Guide – See Wiring Diagrams for location of specified | Observe Safety Guidelines | |||||||

components. See Wiring Diagrams for troubleshooting of specific circuits. | detailed in the beginning of this manual. | |||||||

|

|

|

|

|

|

| ||

PROBLEMS |

| POSSIBLE AREAS OF |

| RECOMMENDED |

| |||

(SYMPTOMS) |

| MISADJUSTMENT(S) |

| COURSE OF ACTION |

| |||

|

|

|

|

|

|

| ||

|

|

| FEEDING PROBLEMS (Continued) |

|

|

| ||

The wire feeds for a short period of | 1. The drive motor may be |

| 1. Check the motor | ar mature | ||||

time but then stops feeding. When | overloaded. | Check the wire |

| current through either of the | ||||

the gun trigger is released and | feeding path for mechanical |

| armature leads (539 or 541). A | |||||

then retriggered, the wire resumes | restrictions. |

|

| typical value is 4 amps DC. | ||||

feeding but soon stops again. | 2. While welding make certain the |

| 2. If 5 amps or less is indicated | |||||

|

|

|

| |||||

|

|

| power source arc voltage is |

| and the armature voltage is | |||

|

|

| staying above 15 VDC. The |

| being disabled by the control | |||

|

|

| feeder will not function properly |

| board, then the control board | |||

|

|

| on less than 15 VDC. |

| may be faulty. Replace. | |||

|

|

|

|

|

|

| 3. If more than 5 | amps is |

|

|

|

|

|

|

| indicated, then the motor is | |

|

|

|

|

|

|

| drawing too much armature | |

|

|

|

|

|

|

| current. Check and or replace | |

|

|

|

|

|

|

| the motor brushes. |

|

|

|

|

|

|

|

| 4. The motor or gearbox may be | |

|

|

|

|

|

|

| faulty. Replace. |

|

|

|

|

| |||||

The wire stops or stubs while | 1. If the |

| 1. Monitor the motor armature | |||||

welding. |

| a constant | current power |

| voltage (leads 539 to 541). | |||

NOTE:On codes above 10100, the | source, the arc voltage may be |

| Normal range is 2 to 23 VDC. | |||||

“dipping” below the 15 VDC |

| If the armature voltage is | ||||||

| motor leads (541 & 539) are | threshold that is essential for |

| proper, then check or replace | ||||

| in Control Board Connector | proper |

| the motor brushes. |

| |||

| J4, pins 13 & 14. |

| 2. Try connecting the |

| 2. If the motor armature voltage is | |||

|

|

|

| |||||

|

|

| a constant | voltage power |

| not correct, then the control | ||

|

|

| source or a flatter slope output. |

| board may be faulty. Replace. | |||

|

|

| 3. Make sure the wire feed mode |

|

|

| ||

|

|

| switch (S3) is in the correct |

|

|

| ||

|

|

| position for the power source |

|

|

| ||

|

|

| being used, and proper speed |

|

|

| ||

|

|

| setting is used for the |

|

|

| ||

|

|

| procedure. |

|

|

|

|

|

|

|

| 4. Check | for | mechanical |

|

|

|

|

|

| restrictions in the wire feed |

|

|

| ||

|

|

| path. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact the Lincoln Electric Service Department for technical troubleshooting assistance before you proceed. Call