Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

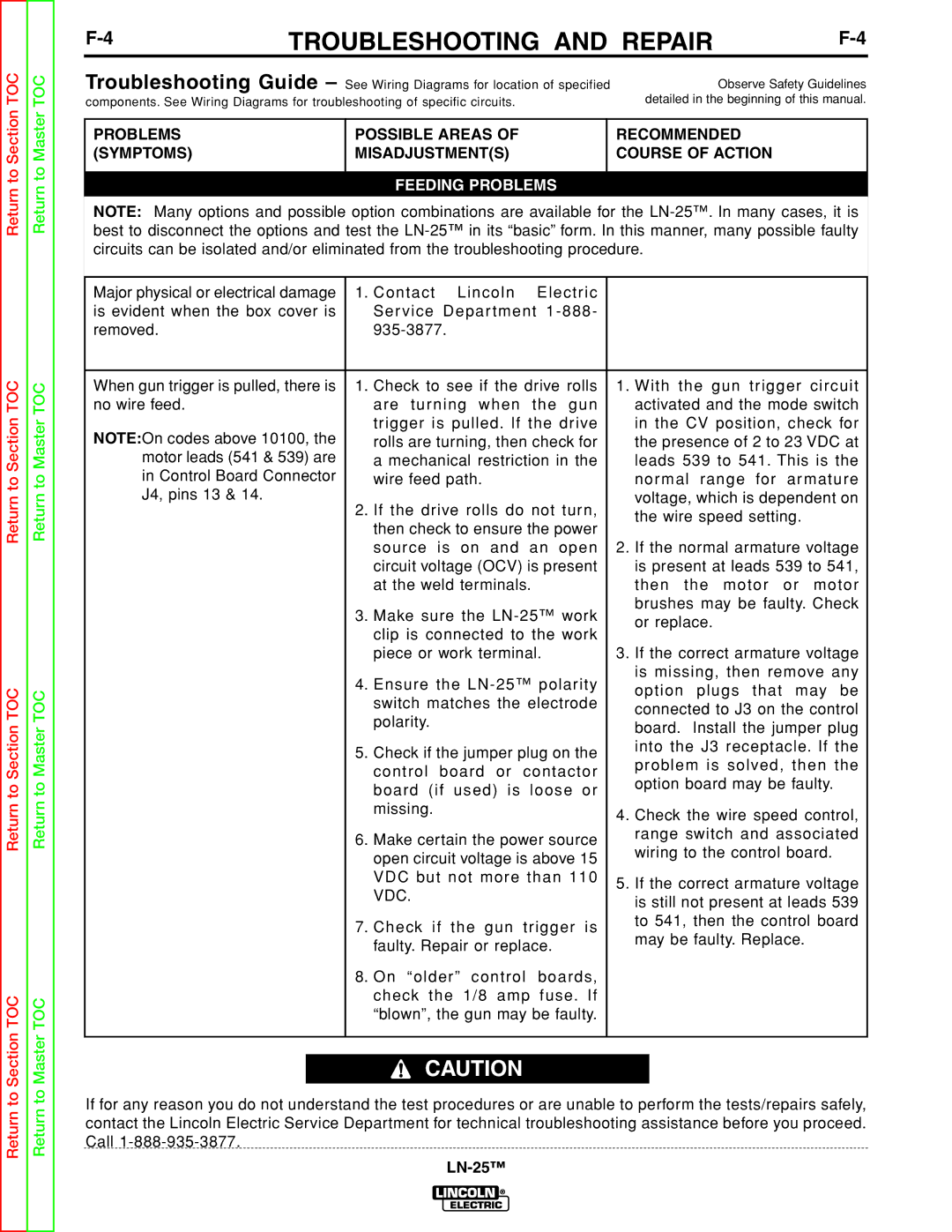

| TROUBLESHOOTING AND REPAIR | |||

|

|

|

|

|

Troubleshooting Guide – See Wiring Diagrams for location of specified | Observe Safety Guidelines | |||

components. See Wiring Diagrams for troubleshooting of specific circuits. | detailed in the beginning of this manual. | |||

|

|

|

|

|

PROBLEMS | POSSIBLE AREAS OF | RECOMMENDED |

| |

(SYMPTOMS) | MISADJUSTMENT(S) | COURSE OF ACTION |

| |

|

|

|

|

|

FEEDING PROBLEMS

NOTE: Many options and possible option combinations are available for the

Major physical or electrical damage | 1. Contact | Lincoln | Electric |

|

is evident when the box cover is | Service Department |

| ||

removed. |

|

|

| |

|

|

| ||

When gun trigger is pulled, there is | 1. Check to see if the drive rolls | 1. With the gun trigger circuit | ||

no wire feed. | are turning when the gun | activated and the mode switch | ||

NOTE:On codes above 10100, the | trigger is pulled. If the drive | in the CV position, check for | ||

rolls are turning, then check for | the presence of 2 to 23 VDC at | |||

motor leads (541 & 539) are | a mechanical restriction in the | leads 539 to 541. This is the | ||

in Control Board Connector | wire feed path. |

| nor mal range for ar mature | |

J4, pins 13 & 14. | 2. If the drive rolls do not turn, | voltage, which is dependent on | ||

| the wire speed setting. | |||

| then check to ensure the power | |||

|

| |||

| source is on and an open | 2. If the normal armature voltage | ||

| circuit voltage (OCV) is present | is present at leads 539 to 541, | ||

| at the weld terminals. | then the motor or motor | ||

| 3. Make sure the | brushes may be faulty. Check | ||

| or replace. | |||

| clip is connected to the work | |||

|

| |||

| piece or work terminal. | 3. If the correct armature voltage | ||

| 4. Ensure the | is missing, then remove any | ||

| option plugs that may be | |||

| switch matches the electrode | |||

| connected to J3 on the control | |||

| polarity. |

|

| |

|

|

| board. Install the jumper plug | |

|

|

|

| |

| 5. Check if the jumper plug on the | into the J3 receptacle. If the | ||

| problem is solved, then the | |||

| control board or | contactor | ||

| option board may be faulty. | |||

| board (if used) is loose or | |||

|

| |||

| missing. |

|

| 4. Check the wire speed control, |

|

|

|

| |

| 6. Make certain the power source | range switch and associated | ||

| wiring to the control board. | |||

| open circuit voltage is above 15 | |||

|

| |||

| VDC but not more than 110 | 5. If the correct armature voltage | ||

| VDC. |

|

| |

|

|

| is still not present at leads 539 | |

|

|

|

| |

| 7. Check if | the gun | trigger is | to 541, then the control board |

| may be faulty. Replace. | |||

| faulty. Repair or replace. | |||

|

| |||

8.On “older” control boards, check the 1/8 amp fuse. If “blown”, the gun may be faulty.

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact the Lincoln Electric Service Department for technical troubleshooting assistance before you proceed. Call