Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

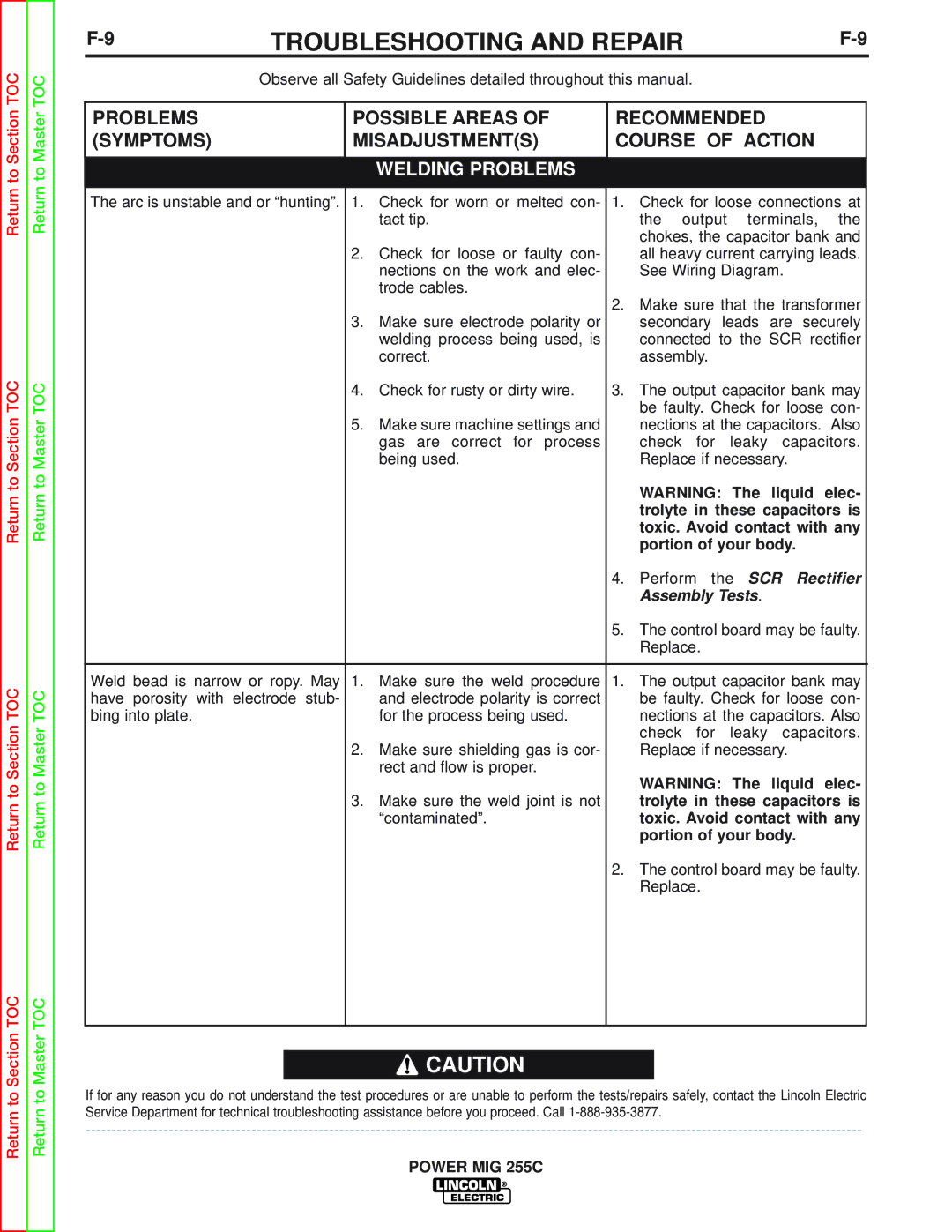

TROUBLESHOOTING AND REPAIR | ||

|

|

|

Observe all Safety Guidelines detailed throughout this manual.

PROBLEMS | POSSIBLE AREAS OF | RECOMMENDED |

| |||

(SYMPTOMS) | MISADJUSTMENT(S) | COURSE OF ACTION | ||||

|

|

|

|

|

|

|

|

| WELDING PROBLEMS |

|

|

|

|

|

|

|

| |||

The arc is unstable and or “hunting”. | 1. | Check for worn or melted con- | 1. Check for loose connections at | |||

|

| tact tip. | the | output terminals, the | ||

|

|

| chokes, the capacitor bank and | |||

| 2. | Check for loose or faulty con- | all heavy current carrying leads. | |||

|

| nections on the work and elec- | See Wiring Diagram. | |||

|

| trode cables. | 2. Make sure that the transformer | |||

|

|

| ||||

| 3. | Make sure electrode polarity or | secondary | leads | are securely | |

|

| welding process being used, is | connected to the SCR rectifier | |||

|

| correct. | assembly. |

|

| |

| 4. | Check for rusty or dirty wire. | 3. The output capacitor bank may | |||

|

|

| be faulty. Check for loose con- | |||

| 5. | Make sure machine settings and | nections at the capacitors. Also | |||

|

| gas are correct for process | check | for | leaky | capacitors. |

|

| being used. | Replace if necessary. | |||

|

|

| WARNING: The liquid elec- | |||

|

|

| trolyte in these capacitors is | |||

|

|

| toxic. Avoid contact with any | |||

|

|

| portion of your body. | |||

|

|

| 4. Perform the SCR Rectifier | |||

|

|

| Assembly Tests. |

| ||

|

|

| 5. The control board may be faulty. | |||

|

|

| Replace. |

|

| |

|

|

|

| |||

Weld bead is narrow or ropy. May | 1. | Make sure the weld procedure | 1. The output capacitor bank may | |||

have porosity with electrode stub- |

| and electrode polarity is correct | be faulty. Check for loose con- | |||

bing into plate. |

| for the process being used. | nections at the capacitors. Also | |||

|

|

| check | for | leaky | capacitors. |

| 2. | Make sure shielding gas is cor- | Replace if necessary. | |||

|

| rect and flow is proper. | WARNING: The liquid elec- | |||

|

|

| ||||

| 3. | Make sure the weld joint is not | trolyte in these capacitors is | |||

|

| “contaminated”. | toxic. Avoid contact with any | |||

|

|

| portion of your body. | |||

|

|

| 2. The control board may be faulty. | |||

|

|

| Replace. |

|

| |

|

|

|

|

|

|

|

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact the Lincoln Electric Service Department for technical troubleshooting assistance before you proceed. Call