Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

TROUBLESHOOTING AND REPAIR |

CONTROL BOARD TEST (continued)

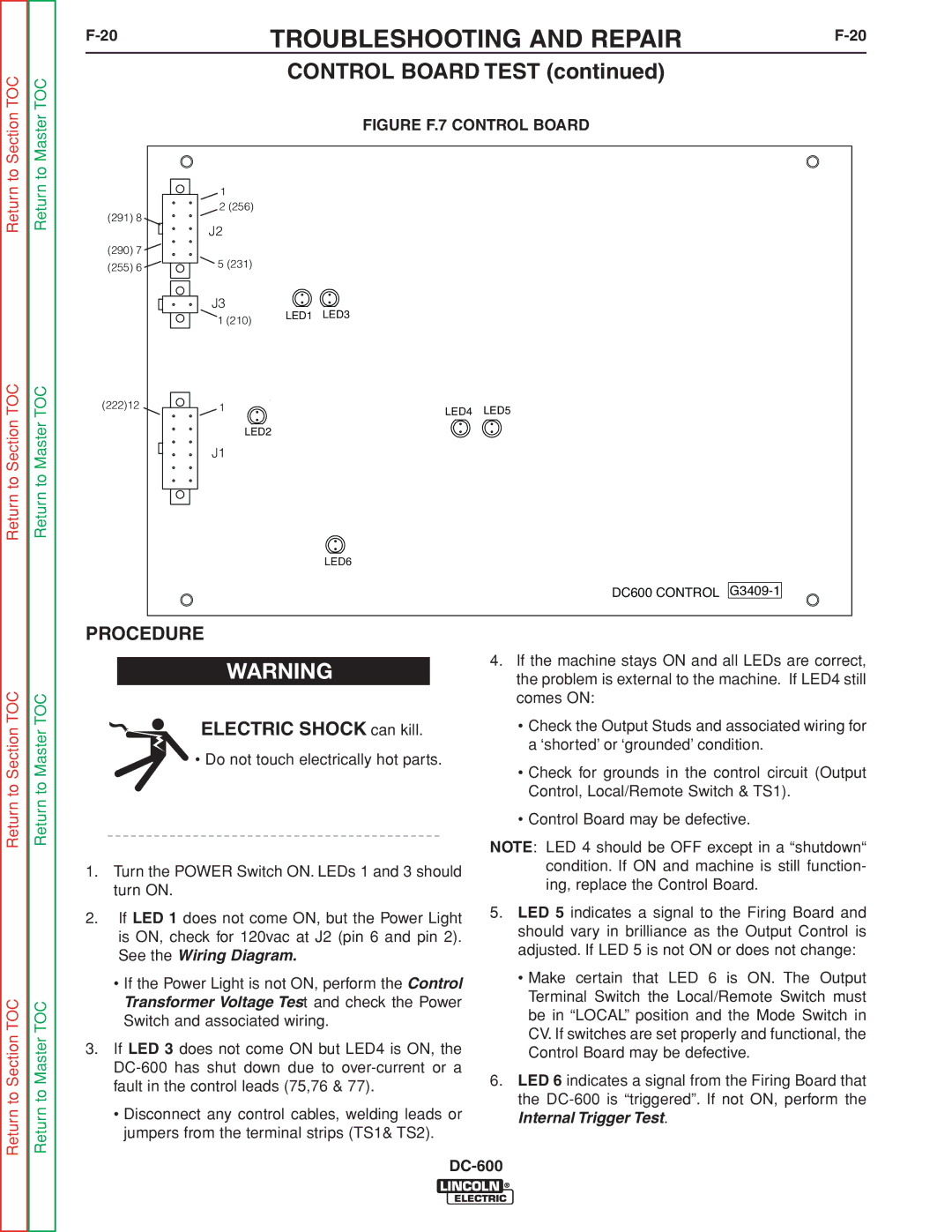

FIGURE F.7 CONTROL BOARD

| 1 |

|

(291) 8 | 2 (256) |

|

J2 |

| |

|

| |

(290) 7 |

|

|

(255) 6 | 5 (231) |

|

|

| |

| J3 | LED1 LED3 |

| 1 (210) | |

|

|

(222)12 | 1 | LED4 | LED5 |

|

|

LED2

J1

LED6

DC600 CONTROL

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

PROCEDURE

![]() WARNING

WARNING

ELECTRIC SHOCK can kill.

•Do not touch electrically hot parts.

1.Turn the POWER Switch ON. LEDs 1 and 3 should turn ON.

2.If LED 1 does not come ON, but the Power Light is ON, check for 120vac at J2 (pin 6 and pin 2). See the Wiring Diagram.

•If the Power Light is not ON, perform the Control Transformer Voltage Test and check the Power Switch and associated wiring.

3.If LED 3 does not come ON but LED4 is ON, the

•Disconnect any control cables, welding leads or jumpers from the terminal strips (TS1& TS2).

4.If the machine stays ON and all LEDs are correct, the problem is external to the machine. If LED4 still comes ON:

•Check the Output Studs and associated wiring for a ‘shorted’ or ‘grounded’ condition.

•Check for grounds in the control circuit (Output Control, Local/Remote Switch & TS1).

•Control Board may be defective.

NOTE: LED 4 should be OFF except in a “shutdown“ condition. If ON and machine is still function- ing, replace the Control Board.

5.LED 5 indicates a signal to the Firing Board and should vary in brilliance as the Output Control is adjusted. If LED 5 is not ON or does not change:

•Make certain that LED 6 is ON. The Output Terminal Switch the Local/Remote Switch must be in “LOCAL” position and the Mode Switch in CV. If switches are set properly and functional, the Control Board may be defective.

6.LED 6 indicates a signal from the Firing Board that the