Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

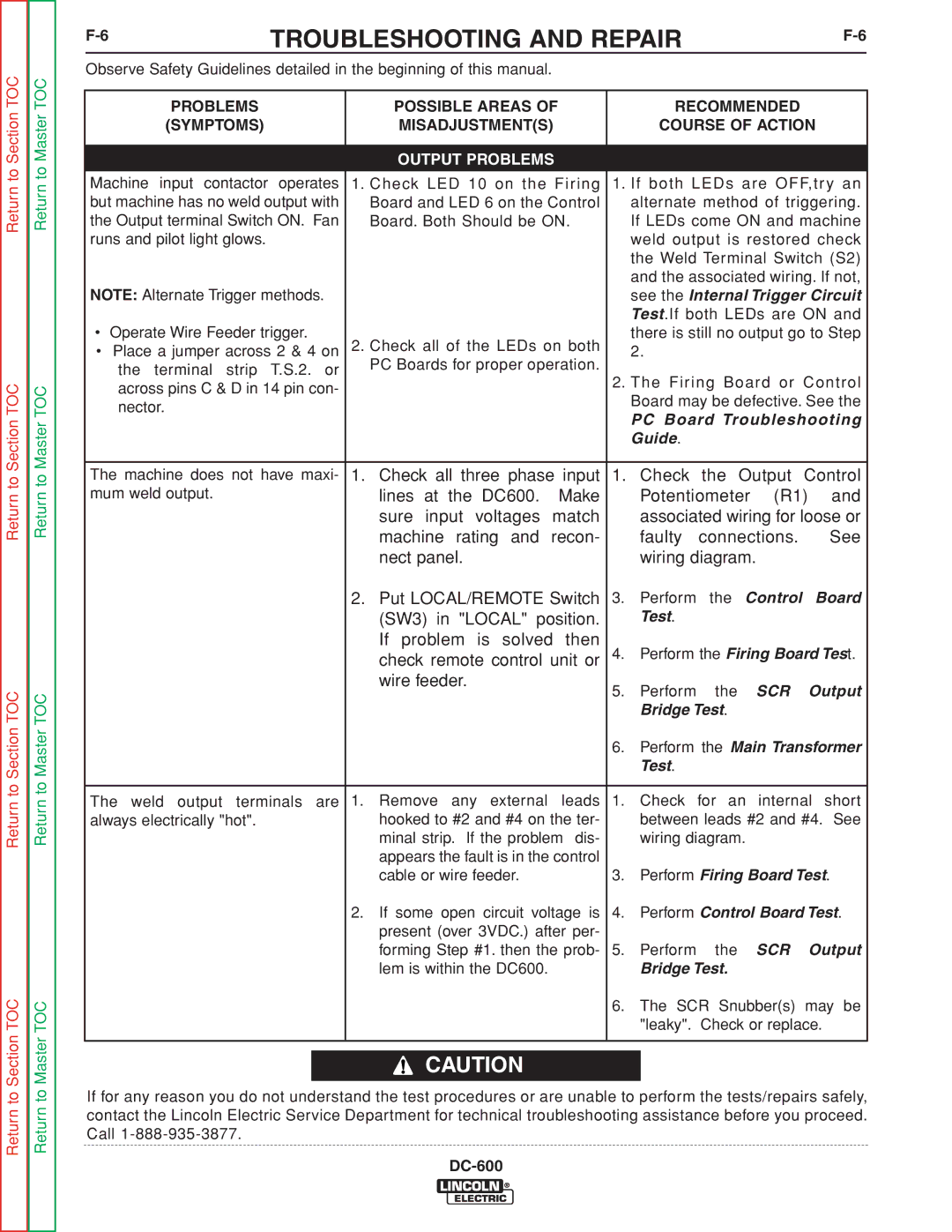

| TROUBLESHOOTING AND REPAIR |

|

| |||||||||

Observe Safety Guidelines detailed in the beginning of this manual. |

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

| |||||

| PROBLEMS |

|

| POSSIBLE AREAS OF |

| RECOMMENDED |

| |||||

| (SYMPTOMS) |

|

| MISADJUSTMENT(S) |

| COURSE OF ACTION | ||||||

|

|

|

|

|

|

|

|

|

| |||

|

|

|

| OUTPUT PROBLEMS |

|

|

|

|

| |||

Machine input contactor | operates | 1. C h e ck L E D 1 0 o n t h e F i r i n g | 1. I f b o t h L E D s a r e O F F, t r y a n | |||||||||

but machine has no weld output with |

| Board and LED 6 on the Control |

| alternate method of triggering. | ||||||||

the Output terminal Switch ON. Fan |

| Board. Both Should be ON. |

| If LEDs come ON and machine | ||||||||

runs and pilot light glows. |

|

|

|

|

|

|

| weld output is restored check | ||||

|

|

|

|

|

|

|

|

| the Weld Terminal Switch (S2) | |||

|

|

|

|

|

|

|

|

| and the associated wiring. If not, | |||

NOTE: Alternate Trigger methods. |

|

|

|

|

|

| see the Internal Trigger Circuit | |||||

|

|

|

|

|

|

|

|

| Test.If both LEDs are ON and | |||

• | Operate Wire Feeder trigger. | 2. Check all of the LEDs on both |

| there is still no output go to Step | ||||||||

• | Place a jumper across 2 & 4 on |

| 2. |

|

|

| ||||||

| PC Boards for proper operation. |

|

|

|

| |||||||

| the terminal strip | T.S.2. or |

|

|

|

|

|

| ||||

|

|

|

|

|

| 2. T h e F i r i n g B o a r d o r C o n t r o l | ||||||

| across pins C & D in 14 pin con- |

|

|

|

|

| ||||||

|

|

|

|

|

|

| Board may be defective. See the | |||||

| nector. |

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

| PC Board Troubleshooting | ||||

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

| Guide. |

|

|

|

|

|

|

|

|

|

|

| |||||

The machine does not have maxi- | 1. | Check all three phase input | 1. | Check | the | Output | Control | |||||

mum weld output. |

|

| lines | at the | DC600. | Make |

| Potentiometer (R1) and | ||||

|

|

|

| sure | input | voltages | match |

| associated wiring for loose or | |||

|

|

|

| machine rating and recon- |

| faulty | connections. | See | ||||

|

|

|

| nect panel. |

|

|

| wiring diagram. |

| |||

|

|

| 2. | Put LOCAL/REMOTE Switch | 3. | Perform | the | Control | Board | |||

|

|

|

| (SW3) in "LOCAL" position. |

| Test. |

|

|

| |||

|

|

|

| If problem is solved then | 4. | Perform the Firing Board Test. | ||||||

|

|

|

| check remote control unit or | ||||||||

|

|

|

| wire feeder. |

|

| 5. | Perform | the | SCR | Output | |

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

| Bridge Test. |

|

| |

|

|

|

|

|

|

|

| 6. | Perform the Main Transformer | |||

|

|

|

|

|

|

|

|

| Test. |

|

|

|

|

|

|

|

|

| |||||||

The weld output terminals are | 1. | Remove any external | leads | 1. | Check for an internal short | |||||||

always electrically "hot". |

|

| hooked to #2 and #4 on the ter- |

| between leads #2 and #4. See | |||||||

|

|

|

| minal strip. If the problem dis- |

| wiring diagram. |

| |||||

|

|

|

| appears the fault is in the control |

|

|

|

|

| |||

|

|

|

| cable or wire feeder. |

| 3. | Perform Firing Board Test. | |||||

|

|

| 2. | If some open circuit voltage is | 4. | Perform Control Board Test. | ||||||

|

|

|

| present (over 3VDC.) after per- |

|

|

|

|

| |||

|

|

|

| forming Step #1. then the prob- | 5. | Perform | the | SCR | Output | |||

|

|

|

| lem is within the DC600. |

|

| Bridge Test. |

|

| |||

|

|

|

|

|

|

|

| 6. | The SCR Snubber(s) may be | |||

|

|

|

|

|

|

|

|

| "leaky". Check or replace. | |||

|

|

|

|

|

|

|

|

|

|

|

|

|

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact the Lincoln Electric Service Department for technical troubleshooting assistance before you proceed. Call