|

| INSTALLATION | |||||

TOC | TOC | ELECTRICAL INPUT CONNECTIONS | INPUT POWER SUPPLYCONNECTIONS |

| |||

|

| A qualified electrician should connect the input power | |||||

Before installing the machine check that the input sup- | supply leads. |

| |||||

Section | Master | ply voltage, phase, and frequency are the same as the | 1. | Follow all national and local electrical codes. |

| ||

|

|

| |||||

|

| voltage, phase, and frequency as specified on the |

| ||||

to | to | welder Rating Plate located | on the Case Back | 2. | Use a |

| |

Assembly. Input power supply entry is through the hole |

| ||||||

Return | Return |

| |||||

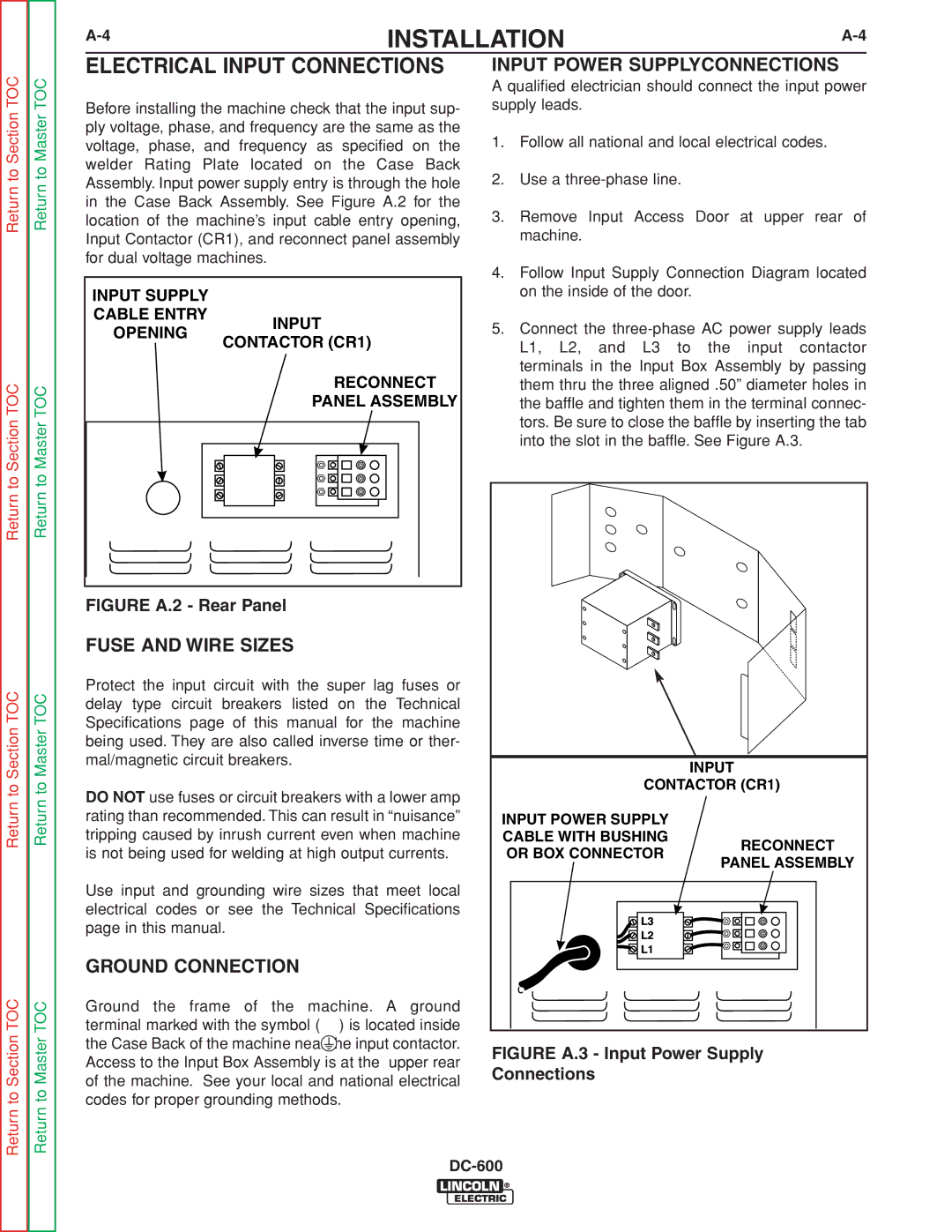

in the Case Back Assembly. See Figure A.2 for the | 3. | Remove Input Access Door at upper rear of | |||||

|

| ||||||

|

| location of the machine’s input cable entry opening, | |||||

|

| Input Contactor (CR1), and reconnect panel assembly |

| machine. |

| ||

|

| for dual voltage machines. |

|

|

|

| |

|

|

|

| 4. Follow Input Supply Connection Diagram located | ||

|

| INPUT SUPPLY |

|

| on the inside of the door. |

|

|

| CABLE ENTRY | INPUT | 5. | Connect the | |

|

| OPENING | ||||

|

| CONTACTOR (CR1) | ||||

|

|

|

| L1, L2, and L3 to the input | contactor | |

|

|

|

|

| ||

|

|

| RECONNECT |

| terminals in the Input Box Assembly by passing | |

TOC | TOC |

|

| them thru the three aligned .50” diameter holes in | ||

| PANEL ASSEMBLY |

| the baffle and tighten them in the terminal connec- | |||

|

|

|

| |||

SectiontoReturn | MastertoReturn |

|

|

| tors. Be sure to close the baffle by inserting the tab | |

|

|

| into the slot in the baffle. See Figure A.3. | |||

|

|

|

|

| ||

FIGURE A.2 - Rear Panel

FUSE AND WIRE SIZES

TOC | TOC | Protect the input circuit with the super lag fuses or |

|

|

|

delay type circuit breakers listed on the Technical |

|

|

| ||

|

|

|

|

| |

Section | Master | Specifications page of this manual for the machine |

|

|

|

being used. They are also called inverse time or ther- |

|

|

| ||

|

|

|

|

| |

|

| mal/magnetic circuit breakers. |

|

|

|

|

|

| INPUT | ||

|

|

|

| ||

to | to | DO NOT use fuses or circuit breakers with a lower amp | CONTACTOR (CR1) | ||

|

|

| |||

Return | Return |

|

|

| |

rating than recommended. This can result in “nuisance” | INPUT POWER SUPPLY |

|

| ||

|

| tripping caused by inrush current even when machine | CABLE WITH BUSHING | RECONNECT | |

|

| is not being used for welding at high output currents. | OR BOX CONNECTOR | ||

|

| PANEL ASSEMBLY | |||

|

|

|

| ||

Use input and grounding wire sizes that meet local electrical codes or see the Technical Specifications page in this manual.

GROUND CONNECTION

TOC | TOC | Ground the frame of the machine. A ground |

| |||

terminal marked with the symbol ( ) is located inside |

| |||||

Section | Connections | |||||

Master | of the machine. See your local and national electrical | |||||

|

| the Case Back of the machine near |

| the input contactor. | FIGURE A.3 - Input Power Supply | |

|

| Access to the Input Box Assembly is at the upper rear | ||||

|

|

| ||||

to | to | codes for proper grounding methods. |

| |||

Return | Return |

|

| |||

|

|

|

| |||