Return to Section TOC

Return to Master TOC

TROUBLESHOOTING AND REPAIR |

SCR RECTIFIER BRIDGE

REMOVAL AND REPLACEMENT PROCEDURE (cont.)

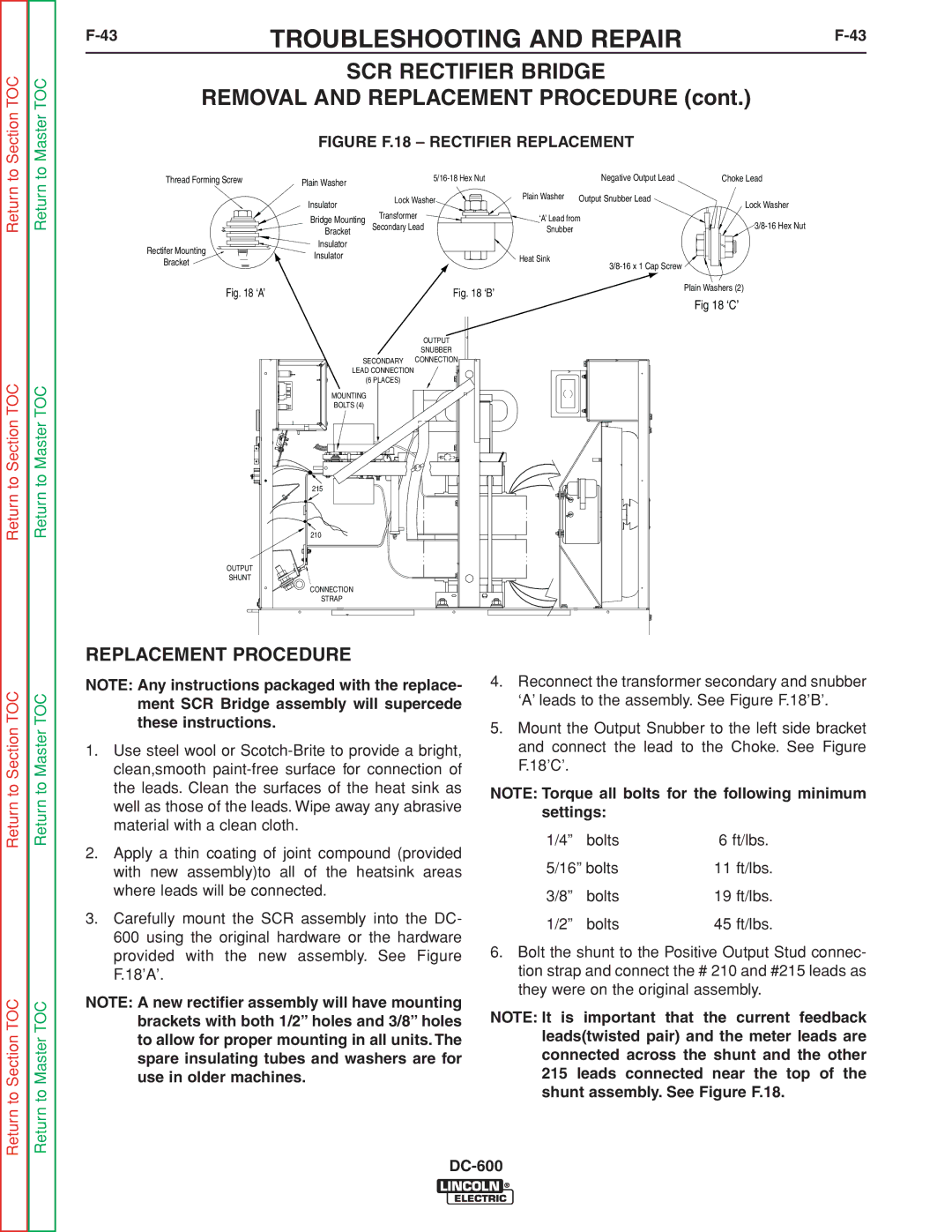

FIGURE F.18 – RECTIFIER REPLACEMENT

Thread Forming Screw | Plain Washer | Negative Output Lead | Choke Lead | |

|

|

|

|

| Insulator | Lock Washer | Plain Washer | Output Snubber Lead |

|

|

| Lock Washer | |

| Bridge Mounting | Transformer | ‘A’ Lead from | |

| Secondary Lead | |||

| Bracket | Snubber | ||

|

|

| ||

Rectifer Mounting | Insulator |

|

|

|

Insulator |

| Heat Sink |

| |

Bracket |

| |||

|

| |||

|

|

| ||

|

|

|

| |

Return to Section TOC

Return to Master TOC

Fig. 18 ‘A’ |

| Fig. 18 ‘B’ |

| |

|

| OUTPUT | A |

|

|

|

|

| |

|

| SNUBBER |

|

|

A | SECONDARY | CONNECTION | A | A |

| ||||

| LEAD CONNECTION | A |

| A |

| A |

|

| |

| (6 PLACES) |

|

|

|

| MOUNTING |

|

|

|

| BOLTS (4) |

|

|

|

|

| A |

| A |

|

| A |

|

|

| A |

| A | |

215 |

|

|

|

|

210 | A |

|

|

|

A |

|

|

|

|

OUTPUT |

| A |

|

|

|

|

|

| |

SHUNT |

|

|

|

|

CONNECTION |

|

|

| |

STRAP |

|

|

| |

| A |

|

|

|

Plain Washers (2)

Fig 18 ‘C’

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

REPLACEMENT PROCEDURE

NOTE: Any instructions packaged with the replace- ment SCR Bridge assembly will supercede these instructions.

1.Use steel wool or

2.Apply a thin coating of joint compound (provided with new assembly)to all of the heatsink areas where leads will be connected.

3.Carefully mount the SCR assembly into the DC- 600 using the original hardware or the hardware provided with the new assembly. See Figure F.18’A’.

NOTE: A new rectifier assembly will have mounting brackets with both 1/2” holes and 3/8” holes to allow for proper mounting in all units. The spare insulating tubes and washers are for use in older machines.

4.Reconnect the transformer secondary and snubber ‘A’ leads to the assembly. See Figure F.18’B’.

5.Mount the Output Snubber to the left side bracket and connect the lead to the Choke. See Figure F.18’C’.

NOTE: Torque all bolts for the following minimum settings:

1/4” | bolts | 6 ft/lbs. | |

5/16” bolts | 11 ft/lbs. | ||

3/8” | bolts | 19 | ft/lbs. |

1/2” | bolts | 45 | ft/lbs. |

6.Bolt the shunt to the Positive Output Stud connec- tion strap and connect the # 210 and #215 leads as they were on the original assembly.

NOTE: It is important that the current feedback leads(twisted pair) and the meter leads are connected across the shunt and the other 215 leads connected near the top of the shunt assembly. See Figure F.18.