ACCESSORIES |

Return to Section TOC

Section TOC

The

When the

Follow these steps to install the

1.Confirm that the

2.Disconnect main AC input power to the

TERMINAL |

STRIP COVER |

BOX |

CONNECTOR |

21+ | 21- 41 | 4 | 2 | 31 32 | 75 76 77 |

|

|

|

|

|

|

| CONTROL |

|

|

|

|

|

| LEADS |

NEGATIVE |

| – |

| + | POSITIVE (+) | |

OUTPUT |

|

|

| OUTPUT | ||

STUD |

|

|

|

|

| STUD |

ELECTRODE | ELECTRODE |

CABLE | CABLE |

WIRE | WORK | + | STICK AIR/CARBON |

|

| ||

|

| ARC WELDING | |

FEEDER |

|

| |

|

| EQUIPMENT | |

| ELECTRODES |

| |

|

|

| |

WORK |

|

| WORK |

CABLE | JUMPER (IF NEEDED | CABLE | |

| SEE INSTRUCTIONS) |

| |

Return to

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

3.Open the terminal strip hinged cover located on the Case Front Assembly.

4.The

5.Route the

6.Connect the control leads from the MULTI- PROCESS SWITCH to terminals #2 and #4 on the

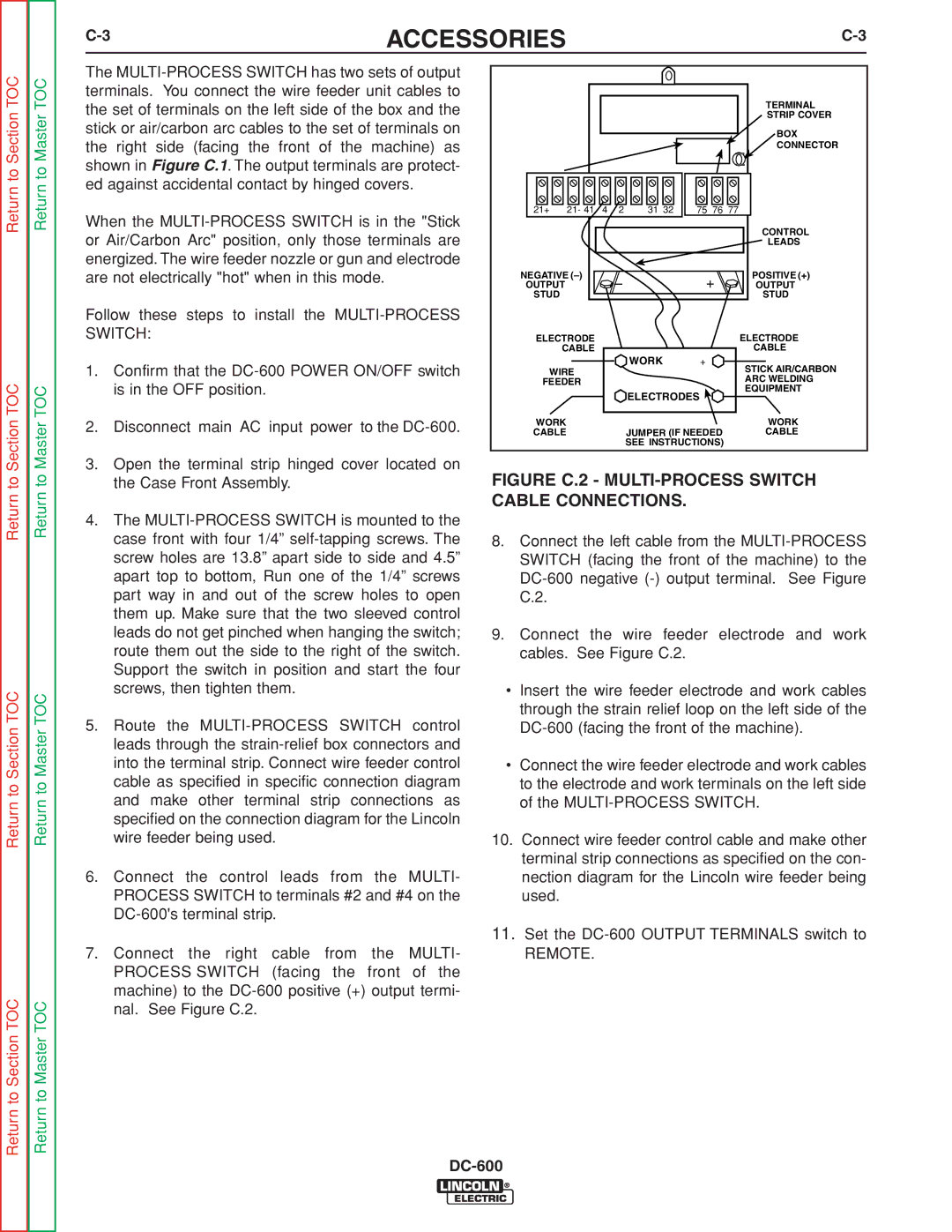

7.Connect the right cable from the MULTI- PROCESS SWITCH (facing the front of the machine) to the

FIGURE C.2 - MULTI-PROCESS SWITCH CABLE CONNECTIONS.

8.Connect the left cable from the

9.Connect the wire feeder electrode and work cables. See Figure C.2.

•Insert the wire feeder electrode and work cables through the strain relief loop on the left side of the

•Connect the wire feeder electrode and work cables to the electrode and work terminals on the left side of the

10.Connect wire feeder control cable and make other terminal strip connections as specified on the con- nection diagram for the Lincoln wire feeder being used.

11.Set the