Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

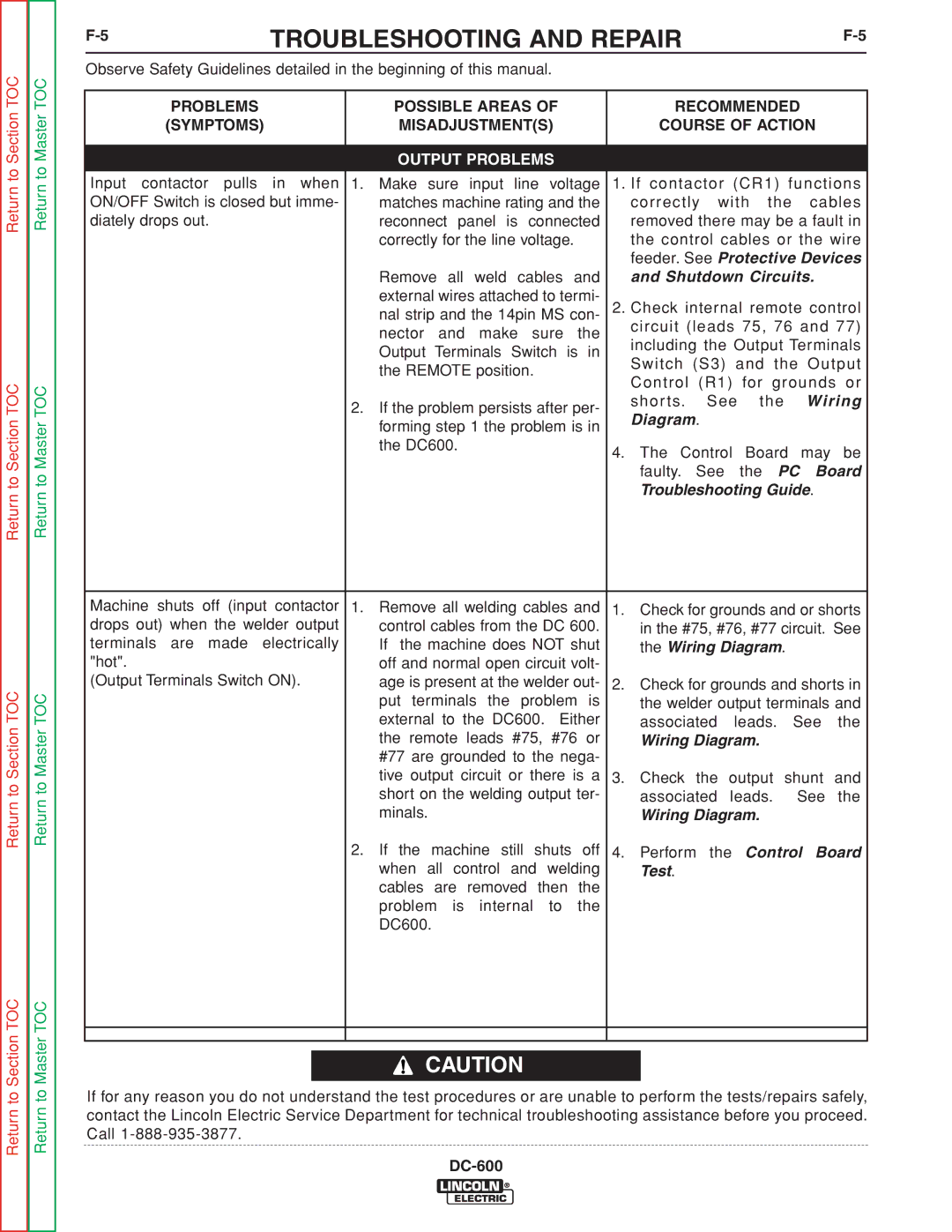

TROUBLESHOOTING AND REPAIR |

|

| |||||||

Observe Safety Guidelines detailed in the beginning of this manual. |

|

|

|

|

| ||||

|

|

|

|

|

|

| |||

| PROBLEMS |

| POSSIBLE AREAS OF |

| RECOMMENDED |

| |||

| (SYMPTOMS) |

| MISADJUSTMENT(S) |

| COURSE OF ACTION |

| |||

|

|

|

|

|

|

|

|

| |

|

|

| OUTPUT PROBLEMS |

|

|

|

|

| |

Input contactor pulls in when | 1. | Make sure input line voltage | 1. I f c o n t a c t o r ( C R 1 ) | f u n c t i o n s | |||||

ON/OFF Switch is closed but imme- |

| matches machine rating and the | c o r r e c t l y w i t h t h e c a bl e s | ||||||

diately drops out. |

| reconnect panel is connected | removed there may be a fault in | ||||||

|

|

| correctly for the line voltage. | the control cables or the wire | |||||

|

|

|

|

|

| feeder. See Protective Devices | |||

|

|

| Remove all weld cables and | and Shutdown Circuits. |

| ||||

|

|

| external wires attached to termi- | 2. Check inter nal remote control | |||||

|

|

| nal strip and the 14pin MS con- | ||||||

|

|

| c i r c u i t ( l e a d s 7 5 , 7 6 a n d 7 7 ) | ||||||

|

|

| nector | and make sure | the | ||||

|

|

| including the Output Terminals | ||||||

|

|

| Output | Terminals Switch | is in | ||||

|

|

| S w i t c h ( S 3 ) a n d t h e O u t p u t | ||||||

|

|

| the REMOTE position. |

| |||||

|

|

|

| C o n t r o l ( R 1 ) fo r gr o u n d s o r | |||||

|

|

|

|

|

| ||||

|

| 2. If the problem persists after per- | s h o r t s. S e e t h e | Wiring | |||||

|

| Diagram. |

|

|

| ||||

|

|

| forming step 1 the problem is in |

|

|

| |||

|

|

|

|

|

|

| |||

|

|

| the DC600. |

| 4. The Control Board may be | ||||

|

|

|

|

|

| ||||

|

|

|

|

|

| faulty. See the PC Board | |||

|

|

|

|

|

| Troubleshooting Guide. |

| ||

|

|

|

| ||||||

Machine shuts off (input contactor | 1. | Remove all welding cables and | 1. Check for grounds and or shorts | ||||||

drops out) when the welder output |

| control cables from the DC 600. | in the #75, #76, #77 circuit. See | ||||||

terminals | are made electrically |

| If the machine does NOT shut | the Wiring Diagram. |

| ||||

"hot". |

|

| off and normal open circuit volt- |

|

|

|

| ||

(Output Terminals Switch ON). |

| age is present at the welder out- | 2. Check for grounds and shorts in | ||||||

|

|

| put terminals the problem is | the welder output terminals and | |||||

|

|

| external to the DC600. Either | associated | leads. | See | the | ||

|

|

| the remote leads #75, #76 or | Wiring Diagram. |

|

| |||

|

|

| #77 are grounded to the nega- |

|

|

|

| ||

|

|

| tive output circuit or there is a | 3. Check the | output | shunt | and | ||

|

|

| short on the welding output ter- | associated | leads. | See | the | ||

|

|

| minals. |

|

| Wiring Diagram. |

|

| |

|

| 2. | If the machine still shuts off | 4. Perform the Control Board | |||||

|

|

| when all control and welding | Test. |

|

|

| ||

|

|

| cables are removed then the |

|

|

|

| ||

|

|

| problem is internal to the |

|

|

|

| ||

|

|

| DC600. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact the Lincoln Electric Service Department for technical troubleshooting assistance before you proceed. Call