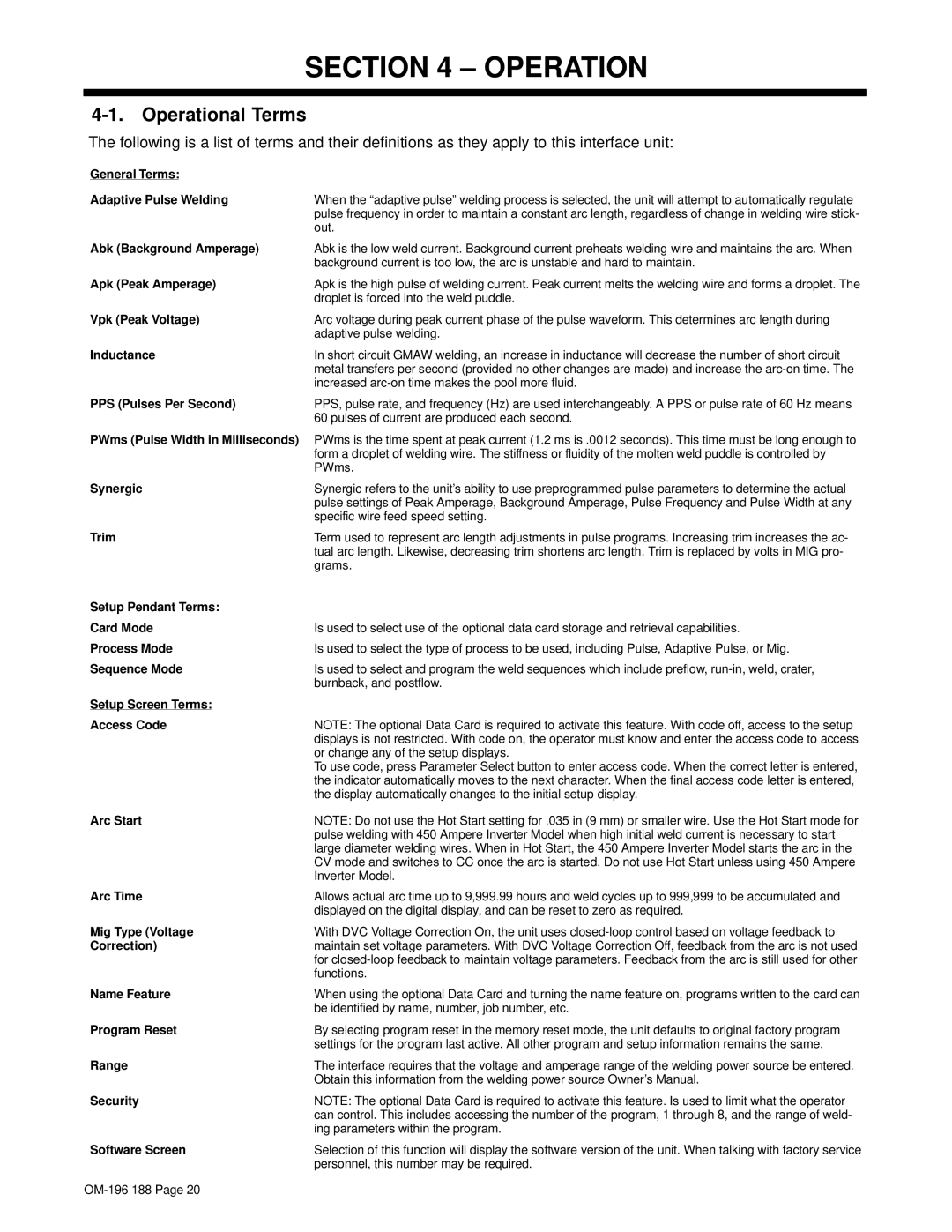

SECTION 4 – OPERATION

4-1. Operational Terms

The following is a list of terms and their definitions as they apply to this interface unit:

General Terms: |

|

Adaptive Pulse Welding | When the “adaptive pulse” welding process is selected, the unit will attempt to automatically regulate |

| pulse frequency in order to maintain a constant arc length, regardless of change in welding wire stick- |

| out. |

Abk (Background Amperage) | Abk is the low weld current. Background current preheats welding wire and maintains the arc. When |

| background current is too low, the arc is unstable and hard to maintain. |

Apk (Peak Amperage) | Apk is the high pulse of welding current. Peak current melts the welding wire and forms a droplet. The |

| droplet is forced into the weld puddle. |

Vpk (Peak Voltage) | Arc voltage during peak current phase of the pulse waveform. This determines arc length during |

| adaptive pulse welding. |

Inductance | In short circuit GMAW welding, an increase in inductance will decrease the number of short circuit |

| metal transfers per second (provided no other changes are made) and increase the |

| increased |

PPS (Pulses Per Second) | PPS, pulse rate, and frequency (Hz) are used interchangeably. A PPS or pulse rate of 60 Hz means |

| 60 pulses of current are produced each second. |

PWms (Pulse Width in Milliseconds) | PWms is the time spent at peak current (1.2 ms is .0012 seconds). This time must be long enough to |

| form a droplet of welding wire. The stiffness or fluidity of the molten weld puddle is controlled by |

| PWms. |

Synergic | Synergic refers to the unit’s ability to use preprogrammed pulse parameters to determine the actual |

| pulse settings of Peak Amperage, Background Amperage, Pulse Frequency and Pulse Width at any |

| specific wire feed speed setting. |

Trim | Term used to represent arc length adjustments in pulse programs. Increasing trim increases the ac- |

| tual arc length. Likewise, decreasing trim shortens arc length. Trim is replaced by volts in MIG pro- |

| grams. |

Setup Pendant Terms: |

|

Card Mode | Is used to select use of the optional data card storage and retrieval capabilities. |

Process Mode | Is used to select the type of process to be used, including Pulse, Adaptive Pulse, or Mig. |

Sequence Mode | Is used to select and program the weld sequences which include preflow, |

| burnback, and postflow. |

Setup Screen Terms: |

|

Access Code | NOTE: The optional Data Card is required to activate this feature. With code off, access to the setup |

| displays is not restricted. With code on, the operator must know and enter the access code to access |

| or change any of the setup displays. |

| To use code, press Parameter Select button to enter access code. When the correct letter is entered, |

| the indicator automatically moves to the next character. When the final access code letter is entered, |

| the display automatically changes to the initial setup display. |

Arc Start | NOTE: Do not use the Hot Start setting for .035 in (9 mm) or smaller wire. Use the Hot Start mode for |

| pulse welding with 450 Ampere Inverter Model when high initial weld current is necessary to start |

| large diameter welding wires. When in Hot Start, the 450 Ampere Inverter Model starts the arc in the |

| CV mode and switches to CC once the arc is started. Do not use Hot Start unless using 450 Ampere |

| Inverter Model. |

Arc Time | Allows actual arc time up to 9,999.99 hours and weld cycles up to 999,999 to be accumulated and |

| displayed on the digital display, and can be reset to zero as required. |

Mig Type (Voltage | With DVC Voltage Correction On, the unit uses |

Correction) | maintain set voltage parameters. With DVC Voltage Correction Off, feedback from the arc is not used |

| for |

| functions. |

Name Feature | When using the optional Data Card and turning the name feature on, programs written to the card can |

| be identified by name, number, job number, etc. |

Program Reset | By selecting program reset in the memory reset mode, the unit defaults to original factory program |

| settings for the program last active. All other program and setup information remains the same. |

Range | The interface requires that the voltage and amperage range of the welding power source be entered. |

| Obtain this information from the welding power source Owner’s Manual. |

Security | NOTE: The optional Data Card is required to activate this feature. Is used to limit what the operator |

| can control. This includes accessing the number of the program, 1 through 8, and the range of weld- |

| ing parameters within the program. |

Software Screen | Selection of this function will display the software version of the unit. When talking with factory service |

| personnel, this number may be required. |

|