Processes

OM-196 188K

Description

From Miller to You

Table of Contents

100

Introduction to Programming

101

Setup

Control Menu

Directives

Standards

Arc Welding Hazards

Symbol Usage

Marks a special safety message

Electric Shock can kill

Flying Metal can injure eyes

ARC Rays can burn eyes and skin

Welding can cause fire or explo- sion

Buildup of GAS can injure or kill

Principal Safety Standards

EMF Information

About Pacemakers

UN Choc Électrique peut tuer

Signification des symboles

Consignes DE Securite Lire Avant Utilisation

LES Fumées ET LES GAZ peuvent être dangereux

DES Pièces Chaudes peuvent pro- voquer des brûlures graves

LE Soudage peut provoquer un incendie ou une explosion

DES Particules Volantes peuvent blesser les yeux

LE Bruit peut affecter l’ouïe

’EMPLOI Excessif peut

Risque D’INCENDIE OU

LA Chute DE L’APPAREIL peut blesser

DES Organes Mobiles peuvent provoquer des blessures

Information sur les champs électromagnétiques

Principales normes de sécurité

Consignes relatives aux stimulateurs cardiaques

Definitions

Manufacturer’s Warning Label Definitions

∠ =

60 s

Harmonic Data

Symbols And Definitions

Manufacturer’s Rating Label

Harmonic Data per IEC 61000-3-12, draft

Specifications

Installation

Dimensions And Weight

Movement Location

Connection Diagram

Selecting a Location

Tipping

10 100% Duty Cycle

Weld Output Terminals And Selecting Cable Sizes

Volts AC Duplex Receptacle And Circuit Breakers

Duty Cycle

Three-Phase

Electrical Service Guide

Connecting Input Power

Always connect grounding conductor first

Rear Panel Connections

Example Receptacle

Peripheral Receptacle Functions

Socket Information

Top View

Touch Sensor Board PC18 Switch S1 Settings

Touch Sensor Operation

Front

Connecting Setup Pendant To Welding Power Source

Turn Off welding power source and weld control

Operation

Operational Terms

Lower Front Panel Controls

Meter Functions

Upper Front Panel Controls

Volt-Ampere Curves

Duty Cycle And Overheating

Overheating

Setup Pendant Controls

Increase Button

Blowing Out Inside Of Unit

Maintenance & Troubleshooting

Routine Maintenance

Months

Removing Case and Measuring Input Capacitor Voltage

Voltmeter/Ammeter Help Displays

Help 1 Display

Front Panel Error Displays

Weld Interface Board PC12 Diagnostic LED’s

LED2 LED4 LED8 LED10 LED11 LED6 LED3 LED5 LED7 LED9 LED12

Diagnostic LED’s On Weld Interface Board PC12

Status Diagnosis

Customer Interface Board PC14 Diagnostic LED’s

Diagnostic LED’s On Customer Interface Board PC14

Motor Board PC13 Diagnostic LED’s

Troubleshooting

Diagnostic LED’s On Motor Board PC13

Trouble Remedy

OM-196 188

Electrical Diagrams

Circuit Diagram For Welding Power Source

203 505-A

Circuit Diagram For Control Board PC1 Part 1

203 311 1

Circuit Diagram For Control Board PC1 Part 2

203 311 2

Circuit Diagram For Control Board PC1 Part 3

203 311 3

Circuit Diagram For Function/Meter Board PC3

190

Circuit Diagram For Interconnect Board PC2

OM-196 188

Circuit Diagram For Interface Module

193 709-A

Circuit Diagram For Microprocessor Board PC11

191

10. Circuit Diagram For Motor Board PC13

212 354-A

11. Circuit Diagram For Switch Board PC15

12. Circuit Diagram For Junction Board PC16

13. Circuit Diagram For Interface Board PC12 Part 1

191 843-A Part 1

14. Circuit Diagram For Interface Board PC12 Part 2

191 843-A Part 2

15. Circuit Diagram For Customer Interface Board PC14 Part 1

Pensar 86147s03 Part 1

16. Circuit Diagram For Customer Interface Board PC14 Part 2

Pensar 86147s03 Part 2

17. Circuit Diagram For Customer Interface Board PC14 Part 3

Pensar 86147s03 Part 3

18. Circuit Diagram For Touch Sensor Board PC18

19. Circuit Diagram For Setup Pendant

200

21. Circuit Diagram For Power Distribution Board PC20

Parts List

Complete Assembly

PLG21

RC10

194 Setup Pendant

Optional

OM-196 188

Programming Instructions for

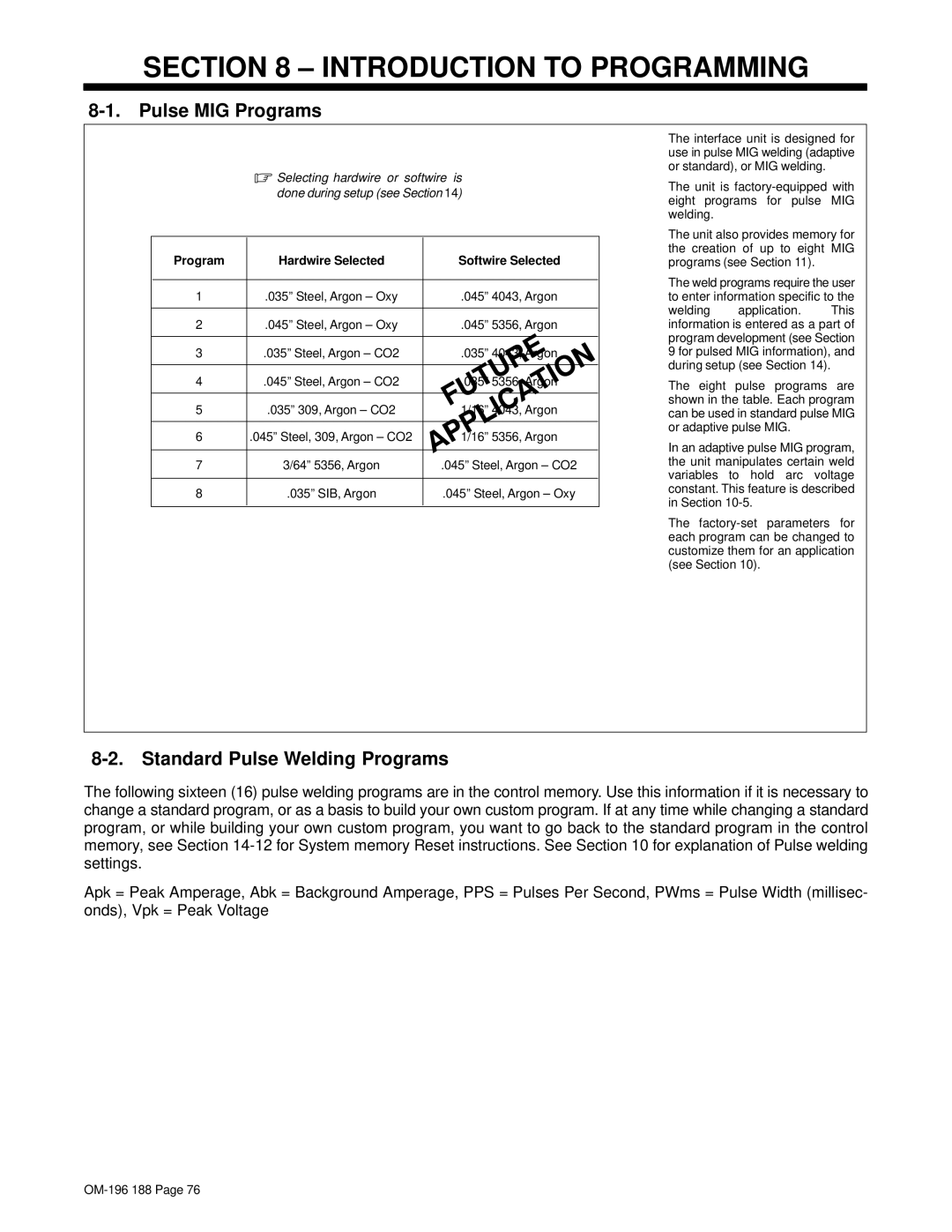

Pulse MIG Programs

Program Hardwire Selected Softwire Selected

Introduction to Programming

Standard Pulse Welding Programs

Program 1 1.2 mm Steel .045, 98-2 Argon-Oxy

Program 2 1.0 mm Steel .040, 80-20 Argon-CO2

Program 4 .8 mm 316 .030, 98-2 Argon-CO2

Program 3 1.2 mm Steel .045, 80-20 Argon-CO2

Gas Ar CO2 / 19 L/min 40 CFH

Program 5 1.0 mm 316 .040, 98-2 Argon-CO2

Program 6 1.2 mm 316 .045, 98-2 Argon-CO2

Program 7 1.0 mm 308L .040, 98-2 Argon-CO2

Program 8 1.2 mm 308L .045, 98-2 Argon-CO2

Program 1 1.2 mm Metal Core .045, 95-5 Argon-CO2

Program 2 1.4 mm Metal Core .052, 95-5 Argon-CO2

Program 3 1.2 mm ER 4043 .045, Argon

Wire Size/Type 1.2 mm .045 ER Gas Ar / 19 L/min 40 CFH

Wire Size/Type 1.0 mm .040 ER Gas Ar / 19 L/min 40 CFH

Program 4 1.0 mm ER 4043 .040, Argon

Program 5 1.0 mm 5356 .040, Argon

Program 6 1.2 mm ER 5356 .045, Argon

Program 8 1.0 mm Steel .040, 98-2 Argon-Oxy

Program 7 .8 mm Steel .030, 98-2 Argon-Oxy

Gas Ar Oxy/ 19 L/min 40 CFH

Setup Pendant Mode Select Button

Setup Pendant Parameter Select Button

Setup Pendant Parameter Increase And Decrease Buttons

Getting Started for Pulse Welding

Setting Preflow Sequence Display

Weld Cycle For Pulse Welding

Setting Weld Sequence Display

Setting Crater Sequence Display

Teaching a Pulse Welding Program

Setting Postflow Sequence Display

Pulse Waveform Explained

Teach Points Explained

IPM

Page

Setting Teach Point Parameters For Pulse Welding Program

PWms Vpk

Wire Size/Type Gas

Card # Gun Model Flowrate

Sec Run-In Trim

Changing To Adaptive Pulse Welding

Teaching a MIG Welding Program

Weld Cycle For Mig Welding

Changing To Mig Welding

Setting Start Sequence Display

Setting Retract Sequence Display

Setting Run-in Sequence Display

Poflw Sec Parameter Select Postflow Parameters Display

Setting SharpArcE Control

Selecting And Adjusting SharpArcE Control

Using the Optional Data Card

Installing Data Card

Using The Data Card

Naming Programs And Writing To Card

Yes

Reading From Card

Reading Or Deleting From An Empty Card

Deleting Programs From Card

Security lock works only when a data card is inserted

Selecting Security Lock

Features Settings Default Section

Setup

Setup Flow Chart

Display Features Settings Default

Using Setup Displays

T u p

Selecting Or Changing Access Code

ZWX

Selecting Auxiliary Output

Selecting Voltage Correction

Selecting Voltage Sensing Method

Resetting Arc Time

Selecting Arc Start Method

Selecting Units For Wire Feed Speed And Motor Type

Selecting Wire Type

Defining Display Value

Resetting Memory

Selecting Arc Start/Volt Sense Error Shutdown

Remote Program Select

Selecting Program Name Feature

Remote Program Setting

Program No Output a Output B Output C

Jog Wire Feed Speed Selection

Flow Selection

Arc Voltage Error Selection

Stick Check Selection

Exiting The Setup Menu

Setting Ramps Function

Software Version Number

Using Menu Display

Control Menu

Setting Rise Time Parameter

Setting Adaptive Parameters

Setting Auto Configure Parameter

Setting Retract On/Off

Setting Sharp Start On/Off

Exiting The Control Menu

Page

Service

Support

Owner’s Record

Miller Electric Mfg. Co