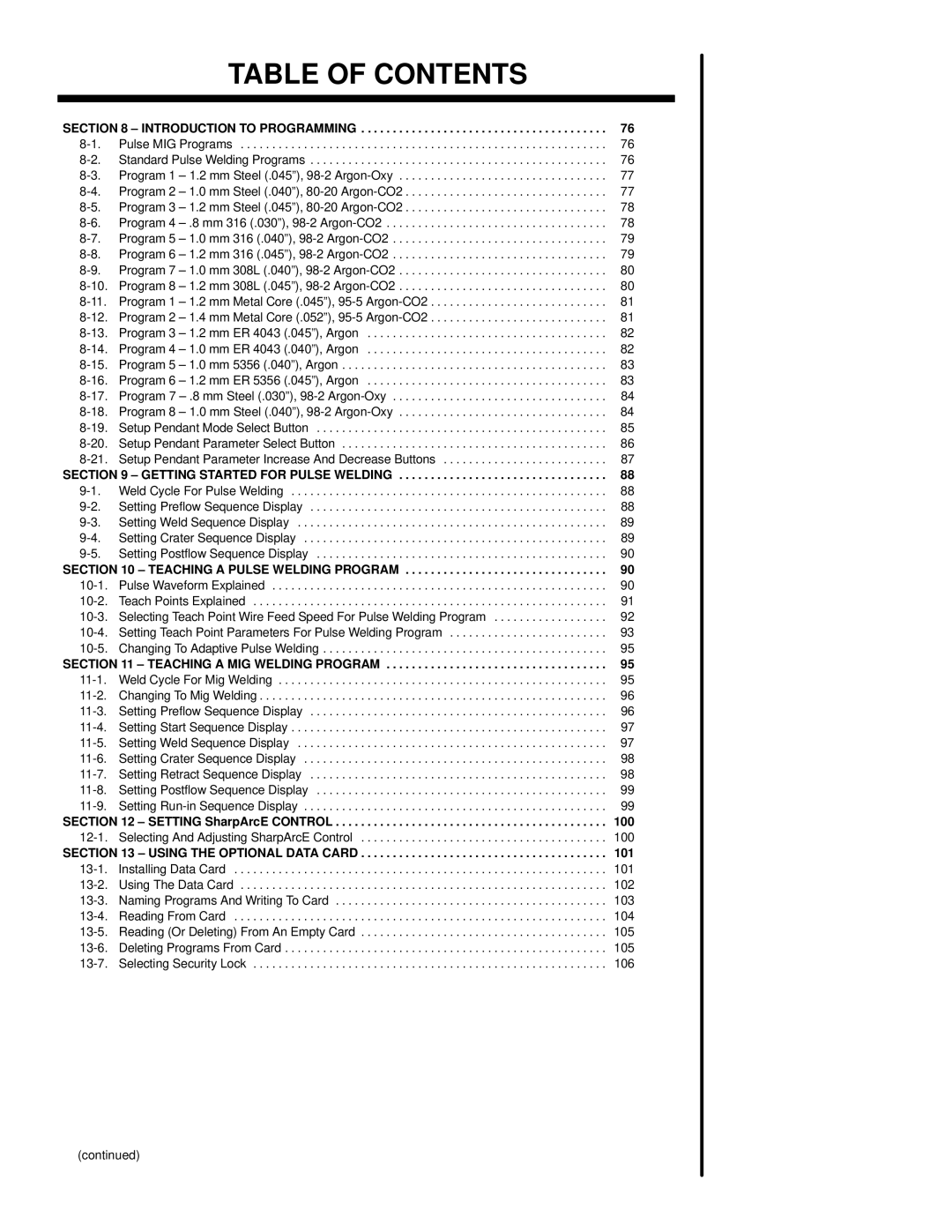

TABLE OF CONTENTS

SECTION 8 – INTRODUCTION TO PROGRAMMING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Pulse MIG Programs | 76 | |

Standard Pulse Welding Programs | 76 | |

Program 1 – 1.2 mm Steel (.045”), | 77 | |

Program 2 – 1.0 mm Steel (.040”), | 77 | |

Program 3 – 1.2 mm Steel (.045”), | 78 | |

Program 4 | 78 | |

Program 5 – 1.0 mm 316 (.040”), | 79 | |

Program 6 – 1.2 mm 316 (.045”), | 79 | |

Program 7 – 1.0 mm 308L (.040”), | 80 | |

Program 8 – 1.2 mm 308L (.045”), | 80 | |

Program 1 – 1.2 mm Metal Core (.045”), | 81 | |

Program 2 – 1.4 mm Metal Core (.052”), | 81 | |

Program 3 – 1.2 mm ER 4043 (.045”), Argon | 82 | |

Program 4 – 1.0 mm ER 4043 (.040”), Argon | 82 | |

Program 5 – 1.0 mm 5356 (.040”), Argon | 83 | |

Program 6 – 1.2 mm ER 5356 (.045”), Argon | 83 | |

Program 7 | 84 | |

Program 8 – 1.0 mm Steel (.040”), | 84 | |

Setup Pendant Mode Select Button | 85 | |

Setup Pendant Parameter Select Button | 86 | |

Setup Pendant Parameter Increase And Decrease Buttons | 87 | |

SECTION 9 – GETTING STARTED FOR PULSE WELDING | 88 | |

| 88 | |

Setting Preflow Sequence Display | 88 | |

Setting Weld Sequence Display | 89 | |

Setting Crater Sequence Display | 89 | |

Setting Postflow Sequence Display | 90 | |

SECTION 10 – TEACHING A PULSE WELDING PROGRAM | 90 | |

Pulse Waveform Explained | 90 | |

Teach Points Explained | 91 | |

Selecting Teach Point Wire Feed Speed For Pulse Welding Program | 92 | |

Setting Teach Point Parameters For Pulse Welding Program | 93 | |

| Changing To Adaptive Pulse Welding | 95 |

SECTION 11 – TEACHING A MIG WELDING PROGRAM | 95 | |

95 | ||

Changing To Mig Welding | 96 | |

Setting Preflow Sequence Display | 96 | |

Setting Start Sequence Display | 97 | |

Setting Weld Sequence Display | 97 | |

Setting Crater Sequence Display | 98 | |

Setting Retract Sequence Display | 98 | |

Setting Postflow Sequence Display | 99 | |

Setting | 99 | |

SECTION 12 – SETTING SharpArcE CONTROL | 100 | |

Selecting And Adjusting SharpArcE Control | 100 | |

SECTION 13 – USING THE OPTIONAL DATA CARD | 101 | |

(continued)