ENGLISH

USER MANUAL

MACHINE STORAGE

If the machine is not going to be used for more than 30 days, proceed as follows:

1.Empty the dust control system water tanks according to the following procedure.

2.Prepare the machine, as shown in the After Machine Use paragraph.

3.Store the machine indoor, in a clean and dry place, protected from bad weather conditions and with the following values:

•Temperature: +1°C to +50°C

•Humidity: maximum 95%

4.Disconnect the negative connector from the battery (18, Fig. E).

5.Handle the diesel engine as shown in the relevant Manual.

WARNING!

When the machine is to be transported or stored at ambient temperatures below 0°C, check that water tanks are empty, disassemble and drain the water fi lter housing.

FIRST PERIOD OF USE

After the fi rst period of use (fi rst 8 hours) it is necessary to perform the following procedures:

Check the fastening and connecting elements for proper tightening. Check the visible parts for integrity and leaks. After the fi rst 50 working hours, perform checks and replacements shown in the Scheduled Maintenance Table.

MAINTENANCE

The lifespan of the machine and its maximum operating safety are ensured by correct and regular maintenance.

The following table provides the scheduled maintenance. The intervals shown may vary according to particular working conditions, which are to be defi ned by the person in charge of the maintenance.

WARNING!

Maintenance procedures must be performed when the machine is off (ignition key removed).

Moreover, read carefully the instructions in Safety chapter before performing any maintenance procedure.

All scheduled or extraordinary maintenance procedures must be performed by qualifi ed personnel, or by an authorised Service Center.

This Manual contains the Scheduled Maintenance Table and describes only the easiest and most common maintenance procedures.

For other maintenance procedures contained in the Scheduled Maintenance Table or for extraordinary maintenance procedures see the Service Manual that can be consulted at any Service Center.

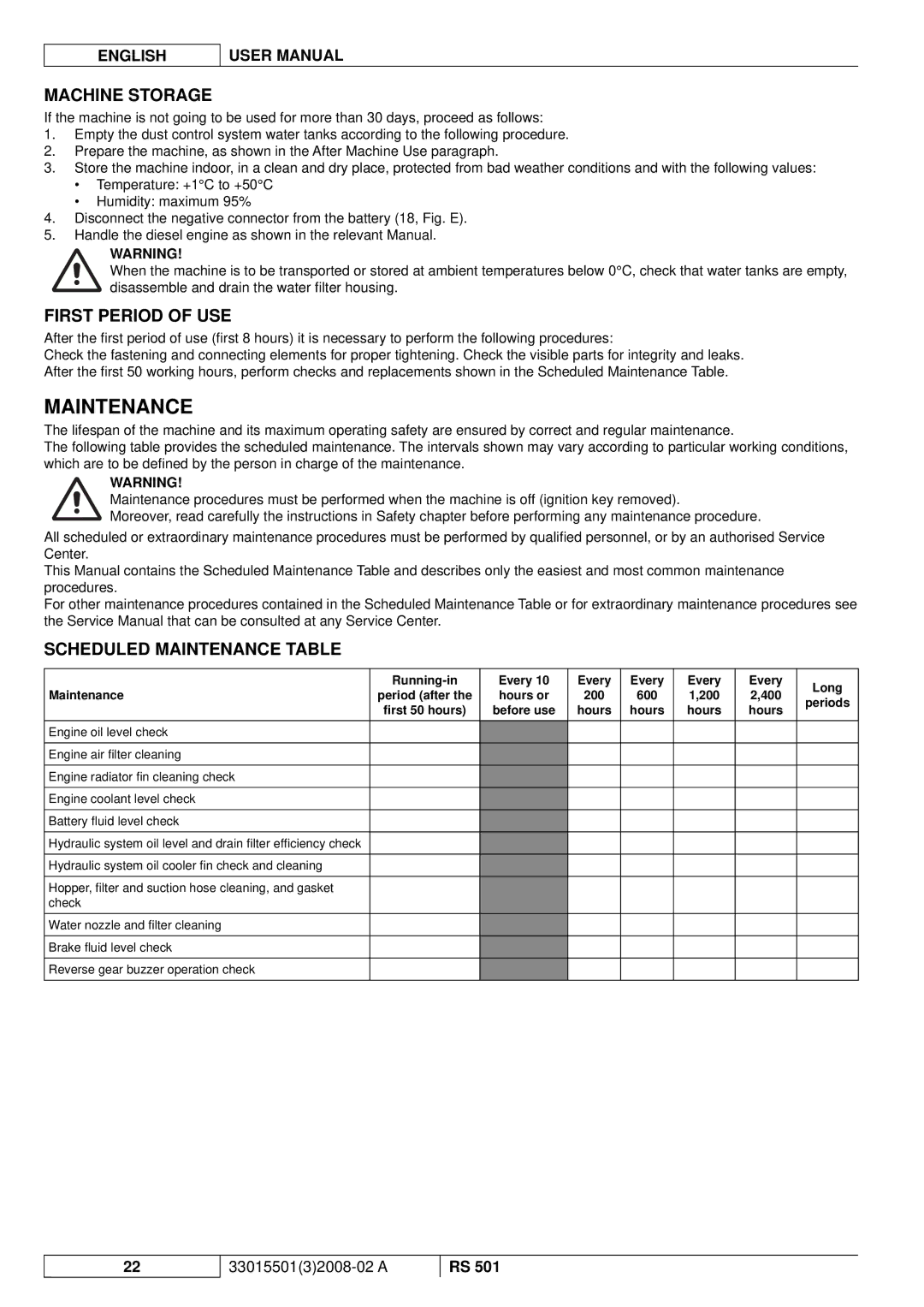

SCHEDULED MAINTENANCE TABLE

| Every 10 | Every | Every | Every | Every | Long | ||

Maintenance | period (after the | hours or | 200 | 600 | 1,200 | 2,400 | ||

periods | ||||||||

| first 50 hours) | before use | hours | hours | hours | hours | ||

|

|

Engine oil level check

Engine air fi lter cleaning

Engine radiator fi n cleaning check

Engine coolant level check

Battery fl uid level check

Hydraulic system oil level and drain fi lter efficiency check

Hydraulic system oil cooler fi n check and cleaning

Hopper, fi lter and suction hose cleaning, and gasket check

Water nozzle and fi lter cleaning

Brake fl uid level check

Reverse gear buzzer operation check

22

33015501(3)2008-02 A

RS 501