USER MANUAL

ENGLISH

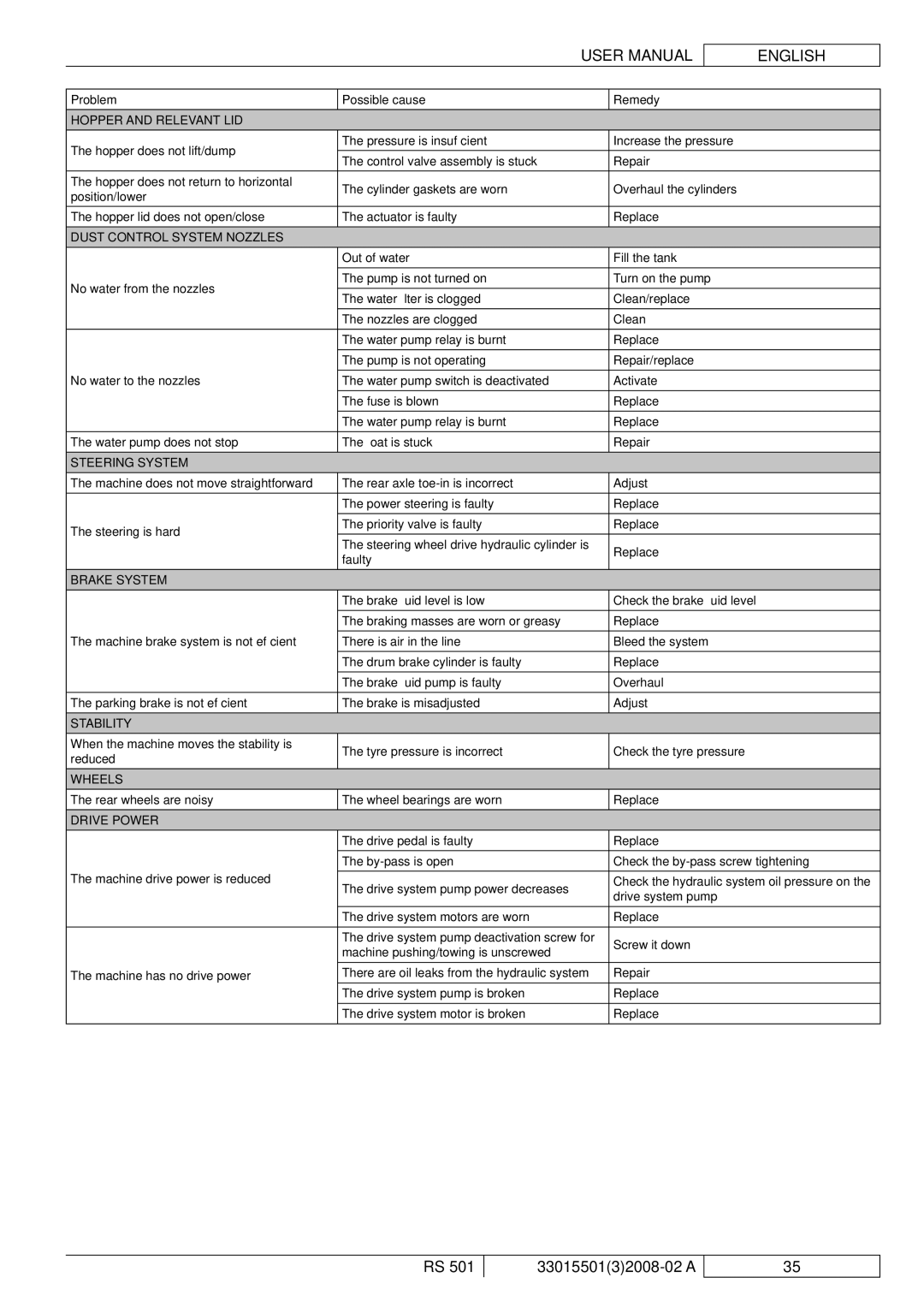

Problem | Possible cause | Remedy | |

HOPPER AND RELEVANT LID |

|

| |

The hopper does not lift/dump | The pressure is insuffi cient | Increase the pressure | |

The control valve assembly is stuck | Repair | ||

| |||

The hopper does not return to horizontal | The cylinder gaskets are worn | Overhaul the cylinders | |

position/lower | |||

|

| ||

The hopper lid does not open/close | The actuator is faulty | Replace | |

DUST CONTROL SYSTEM NOZZLES |

|

| |

| Out of water | Fill the tank | |

No water from the nozzles | The pump is not turned on | Turn on the pump | |

The water fi lter is clogged | Clean/replace | ||

| |||

| The nozzles are clogged | Clean | |

| The water pump relay is burnt | Replace | |

| The pump is not operating | Repair/replace | |

No water to the nozzles | The water pump switch is deactivated | Activate | |

| The fuse is blown | Replace | |

| The water pump relay is burnt | Replace | |

The water pump does not stop | The fl oat is stuck | Repair | |

STEERING SYSTEM |

|

| |

The machine does not move straightforward | The rear axle | Adjust | |

| The power steering is faulty | Replace | |

The steering is hard | The priority valve is faulty | Replace | |

The steering wheel drive hydraulic cylinder is | Replace | ||

| |||

| faulty | ||

|

| ||

BRAKE SYSTEM |

|

| |

| The brake fl uid level is low | Check the brake fl uid level | |

| The braking masses are worn or greasy | Replace | |

The machine brake system is not effi cient | There is air in the line | Bleed the system | |

| The drum brake cylinder is faulty | Replace | |

| The brake fl uid pump is faulty | Overhaul | |

The parking brake is not effi cient | The brake is misadjusted | Adjust | |

STABILITY |

|

|

When the machine moves the stability is reduced

The tyre pressure is incorrect

Check the tyre pressure

WHEELS

The rear wheels are noisy

The wheel bearings are worn

Replace

DRIVE POWER

| The drive pedal is faulty | Replace |

| The | Check the |

The machine drive power is reduced | The drive system pump power decreases | Check the hydraulic system oil pressure on the |

| drive system pump | |

|

| |

| The drive system motors are worn | Replace |

| The drive system pump deactivation screw for | Screw it down |

| machine pushing/towing is unscrewed | |

|

| |

The machine has no drive power | There are oil leaks from the hydraulic system | Repair |

| The drive system pump is broken | Replace |

| The drive system motor is broken | Replace |

RS 501

33015501(3)2008-02 A

35