SHOCK AND VIBRATION

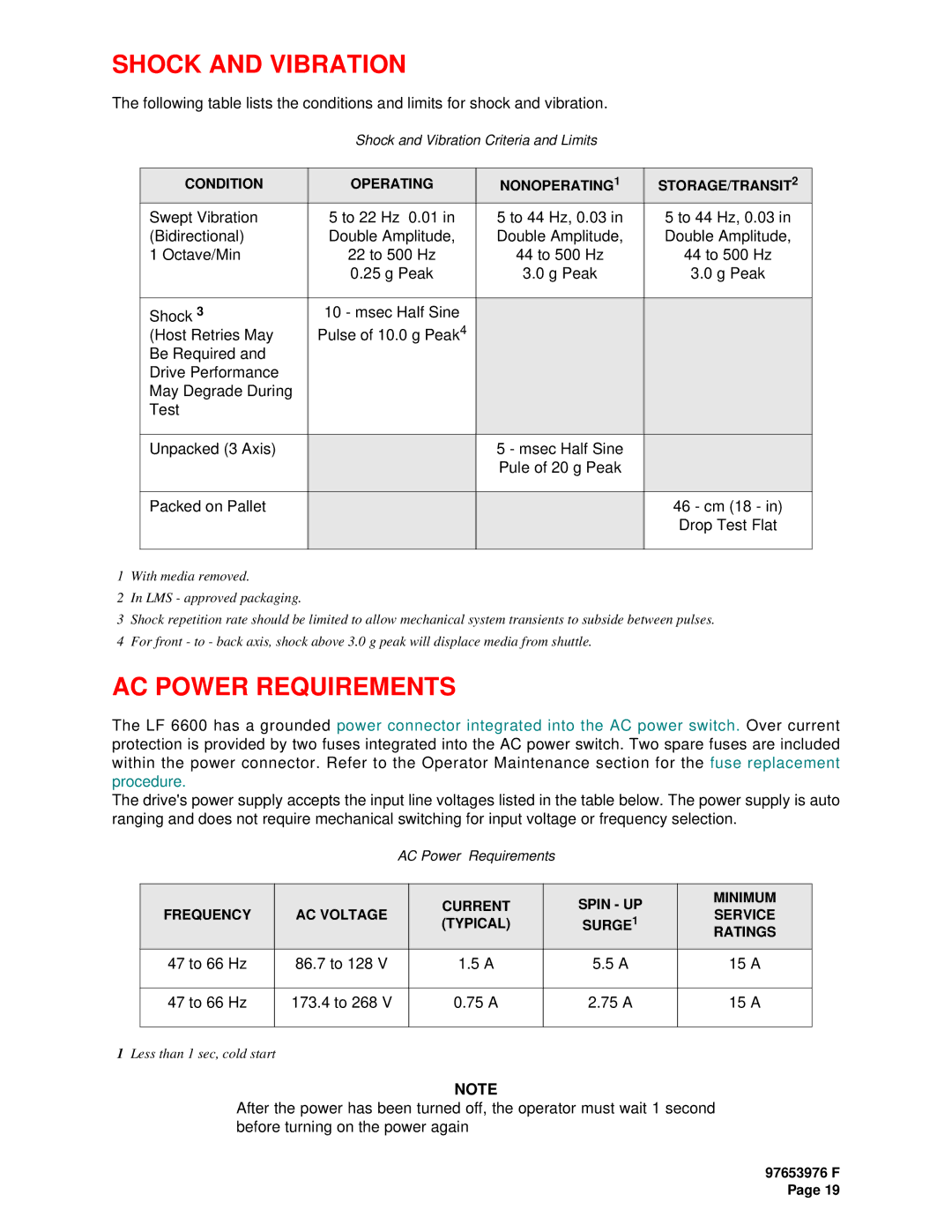

The following table lists the conditions and limits for shock and vibration.

Shock and Vibration Criteria and Limits

CONDITION | OPERATING | NONOPERATING1 | STORAGE/TRANSIT2 |

Swept Vibration | 5 to 22 Hz 0.01 in | 5 to 44 Hz, 0.03 in | 5 to 44 Hz, 0.03 in |

(Bidirectional) | Double Amplitude, | Double Amplitude, | Double Amplitude, |

1 Octave/Min | 22 to 500 Hz | 44 to 500 Hz | 44 to 500 Hz |

| 0.25 g Peak | 3.0 g Peak | 3.0 g Peak |

|

|

|

|

Shock 3 | 10 - msec Half Sine |

|

|

(Host Retries May | Pulse of 10.0 g Peak4 |

|

|

Be Required and |

|

|

|

Drive Performance |

|

|

|

May Degrade During |

|

|

|

Test |

|

|

|

|

|

|

|

Unpacked (3 Axis) |

| 5 - msec Half Sine |

|

|

| Pule of 20 g Peak |

|

|

|

|

|

Packed on Pallet |

|

| 46 - cm (18 - in) |

|

|

| Drop Test Flat |

|

|

|

|

1With media removed.

2In LMS - approved packaging.

3Shock repetition rate should be limited to allow mechanical system transients to subside between pulses.

4For front - to - back axis, shock above 3.0 g peak will displace media from shuttle.

AC POWER REQUIREMENTS

The LF 6600 has a grounded power connector integrated into the AC power switch. Over current protection is provided by two fuses integrated into the AC power switch. Two spare fuses are included within the power connector. Refer to the Operator Maintenance section for the fuse replacement procedure.

The drive's power supply accepts the input line voltages listed in the table below. The power supply is auto ranging and does not require mechanical switching for input voltage or frequency selection.

AC Power Requirements

|

| CURRENT | SPIN - UP | MINIMUM | |

FREQUENCY | AC VOLTAGE | SERVICE | |||

(TYPICAL) | SURGE1 | ||||

|

| RATINGS | |||

|

|

|

| ||

|

|

|

|

| |

47 to 66 Hz | 86.7 to 128 V | 1.5 A | 5.5 A | 15 A | |

|

|

|

|

| |

47 to 66 Hz | 173.4 to 268 V | 0.75 A | 2.75 A | 15 A | |

|

|

|

|

|

1Less than 1 sec, cold start

NOTE

After the power has been turned off, the operator must wait 1 second before turning on the power again

97653976 F Page 19