„ R410A Models Indoor Units

Outdooe Units

Page

Check of Density Limit

Contents

Contents

Test RUN

Test Run

Preparing for Test Run

Test Run Procedure

Items to Check Before the Test Run

Setting of Unit Control PCB

Main Outdoor Unit PCB Setting

No. of outdoor units Outdoor unit setting S006

Indoor unit setting S004 Rotary switch, red

System address S003 System address No P DIP switch, blue 10

Unit No. setting

Auto Address Setting Basic wiring diagram Example

Auto Address Setting

Automatic Address Setting from the Outdoor Unit

Refrigerant

22-9

Circuit

On the No

Case 2 Automatic Address Setting no compressor operation

Automatic Address Setting from Outdoor Unit

Units

Case 3A Automatic Address Setting in Heating Mode

Automatic Address Setting* from the Remote Controller

Case 3B Automatic Address Setting in Cooling Mode

Remote controller display

Display during automatic address setting

On outdoor main unit PCB

Remote Controller Test Run Settings

Auto Address Setting Remote Controller Test Run Settings

If 1 indoor unit is connected to 1 remote controller

Use the remote controller to check the indoor unit address

Test Run

Alarm contents

Meaning of Alarm Messages

Possible cause of malfunction

P02

Alarm messages displayed on system controller

Timer Remote Controller RCS-TM80BG

Wireless Remote Controller

Main Operating Functions

Thermostat is turned ON/OFF according to as shown below

Room Temperature Control

Main Operating Functions

Deg

Operating mode change Shifted set temp

After the compressor turns on

Transmitter

Wireless Remote Controller

Mode button

FAN Speed selector button

Address button

Cool mode and Dry mode, if the flaps are set in a downward

Filter button

C Sensor button

OFF Timer

Indicator when swing operation is stopped

Timer SET button

OFF Cycle Timer

Receiver

Multiple units Group

Temperature sensors at the indoor unit side are used

Operation

Control

How to install batteries

Using the Wireless Remote Control Unit

Cover

Address Settings

Type

D type

Shutdown

Emergency Operation

Operation

Control unit will not be accepted

Press the Emergency operation button once more

Trouble Possible Cause Remedy

Troubleshooting

Trouble Possible Cause

Timer Remote Controller RCS-TM80BG

How to Use the Timer Remote Controller Operating buttons

Names and Operations

Timer program

Display Section Refer to Setting indication

Timer No. indication

Timer OFF indication

Installation Manual for Timer Remote Controller

How to install the Remote Controller

Indoor Unit Setting Mode

Group Control Using 2 Remote Controllers

Remote Controller Setting Mode

To Display the Sensor Temperature

13/32

Set to today’s day of the week

Setting the Present Time

Once you enter in the setting mode Day and time fl ash

Press To change the present hour in the range of 0 to 23

Press To enter the program confirmation mode Start setting

Weekly Program Function Checking Weekly Timer

Program image diagram

Select a Timer number

Set the hour. program step

Set the minute. program step

Pattern

Press / to change the temperature setting

Set the program pattern. program step

Indoor unit starts operation at the programmed time

If Power Failure Occurred

How to invalidate the program timer

How to cancel the program timer invalidation

Deleting the Program Timer

Select the copy source

Duplicating the Program Timer

You can duplicate the preset program by day

Before Asking Repair Work

Room temperature

Precautions

„ For Example Setting at Outing Temperature 86F 30C

Outing Function

Outing function indication

Canceling the outing function

Outing function indication Status

Sleeping Function

Wired Remote Controller Test Run Settings

Procedure

Simple Settings Function

List of Simple Setting Items

Detailed Settings Functions

Setting data

List of Detailed Setting Items

Description

Item code Setting data Description

Setting data

Code Description

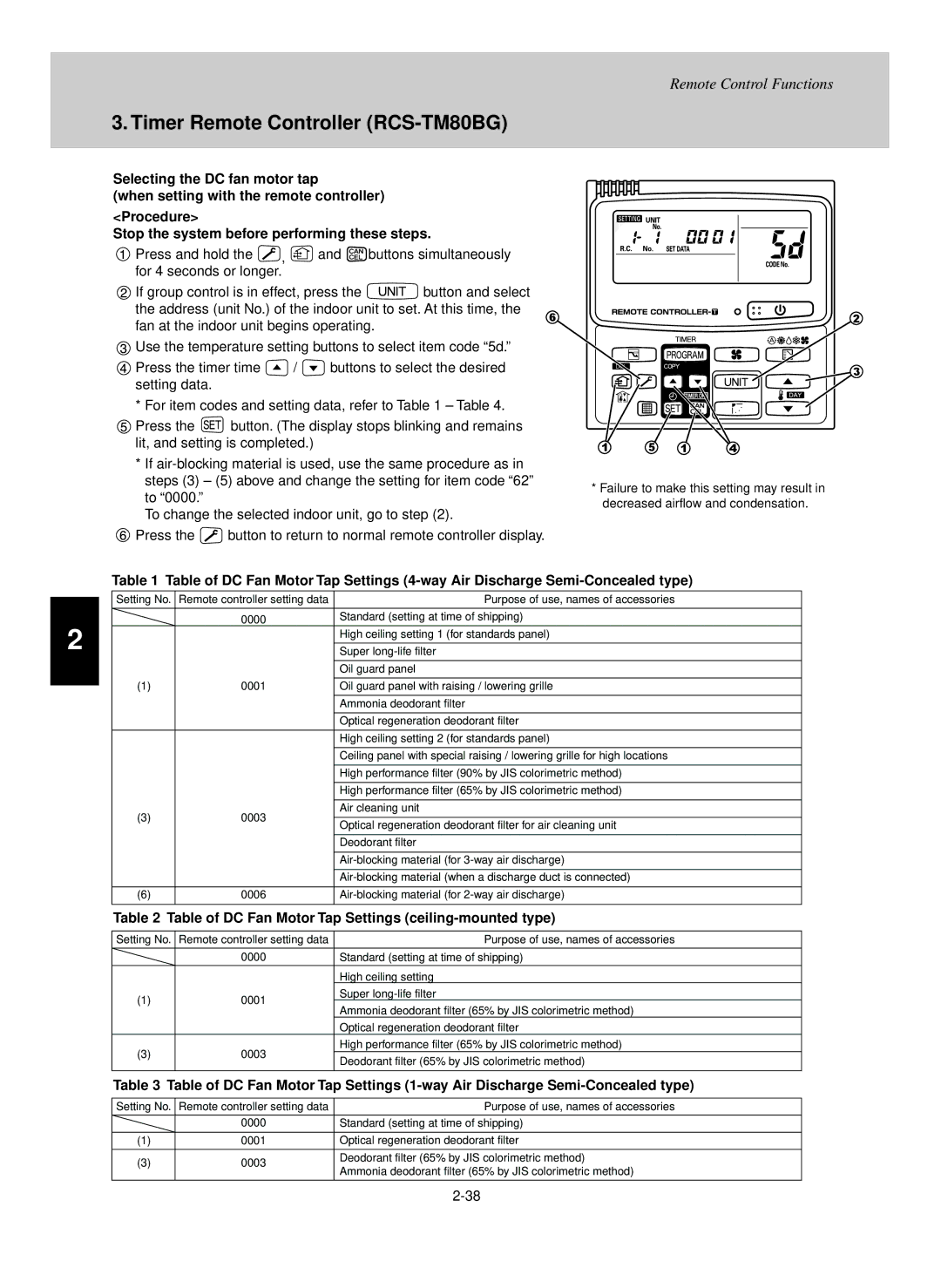

Timer Remote Controller RCS-TM80BG

Table of DC Fan Motor Tap Settings ceiling-mounted type

TP6 TP3 TP1

Display Sensor Servicing check Alarm history Press and hold

Remote Controller Servicing Functions

Maintained

Test Run Function

Normal remote controller display

Trouble Diagnosis

Contents of Remote Controller Switch Alarm Display

Heat exchanger 1 gas temp. sensor F06

OFF

Are occurring Automatic address setting is in progress

Number that was set Alarm display

Display meaning

2WAY ECO-i Alarm Codes

Alarm code Alarm meaning

E12 Alarm Alarm code

E06 Alaral rm Alarm code

Alarm E04 occurs

E15 Alarm Alarm code

E24 Alarm Alarm code

E16 Alarm Alarm code

E20 Alarm Alarm code

At a number of indoor units

E29 Alarm Alarm code

E25 Alarm Alarm code

E26 Alarm Alarm code

Power at the outdoor unit main is turned OFF

Check Check for crossed wiring and installation errors

F04, F05, F22 Alarm Alarm code

Crossed wiring or installation error

Outdoor unit control PCB

F07, F24 Alarm Alarm code

Identification of the problem in this case

F06, F23 Alarm Alarm code

Alarm meaning

F17 Alarm Alarm code

Alarm code F12

F16 Alarm Alarm code

F08

F31 Alarm Alarm code

H03 alarm Alarm code

Which may damage the compressor

H06 Alarm Alarm code

On the degree of the problem

Valve must be replaced

H11, H12, H21, H22 Alarm Alarm code

H13, H23 Alarm Alarm code

H05, H15, H25 Alarm Alarm code

L04 Alarm Alarm code

H31 Alarm Alarm code

L05 Alarm Alarm code

L17 Alarm Alarm code

L06 Alarm Alarm code

L10 Alarm Alarm code

L18 alarm Alarm code

P03, P17, P18 Alarm Alarm code

P04 Alarm Alarm code

Primary or secondary current

P05 Alarm Alarm code

P16 Alarm Alarm code

Noise in some cases

P26 Alarm Alarm code

P22 Alarm Alarm code

P29 Alarm Alarm code

Alarm code Blinking Inspection display

Blinking inspection display 1 Automatic backup

Compressor magnet SW seizing detection

Within that refrigerant tubing system are stopped

Alarm meaning Compressor magnet SW seizing detected

Alarm may be caused by the effects of noise. See notes

Corresponding outdoor unit

Page

PCB and Functions

Outdoor Unit Control PCB

Outdoor Unit Control PCB CR-CHDX14053

Progress will stop the automatic address setting operation

Functions for CR-CHDX14053

Mode. Static signal

Outdoor Unit Control PCB

Setting the Outdoor Unit address S007 Setting Address

Link wiring

System only

T10

Indoor Unit Control PCB

JP1

For AC Fan Motor CR-UXRP71B-B

For DC Fan Motor CR-SXRP56B-B

CR1 for CR-KR74GXH56A/KHX0752~KHX1852 Wall-Mounted

CR1 for CR-KR254GXH56A/KHX2452 Wall-Mounted

CR2 for POW-KR74GXH56/KHX0752~KHX2452 Wall-Mounted

Or less

Signal. Jumper wire cut Static signal continuous signal

CN017

Option

CN014

SELF-DIAGNOSIS Function Table

Self-Diagnosis Function Table

Alarm displayAlarm description

Self-Diagnosis Function Table

Trouble Cause and correction

Check items E15 E16 E20

Cause

Alarm code Alarm meaning

DISCH2

Service Checker

System Diagram

Outdoor Unit Maintenance Remote Controller

Functions Functions on the ordinary display

Cooling/heating change Fig

Temperature monitor

All units start/stop Fig

All units test run Fig

Item codes can be changed with Buttons

Display functions

Item code Remarks

XX-YY R.C

Sample display -4, Fig

Sample Display A, B

Indoor unit

Monitoring Operations

Display of unit No main unit

Outdoor unit

Outdoor Unit Alarm History Monitor

„ Setting mode

Code Parameter Description SET Data

„ Setting mode

Parameter Description SET Data

Page

200706MDC

![]() Press and hold the

Press and hold the ![]() ,

, ![]() and

and ![]() buttons simultaneously for 4 seconds or longer.

buttons simultaneously for 4 seconds or longer.![]() Use the temperature setting buttons to select item code “5d.”

Use the temperature setting buttons to select item code “5d.”![]() Press the timer time

Press the timer time ![]() /

/ ![]() buttons to select the desired setting data.

buttons to select the desired setting data.![]() Press the

Press the ![]() button. (The display stops blinking and remains lit, and setting is completed.)

button. (The display stops blinking and remains lit, and setting is completed.)![]() Press the

Press the ![]() button to return to normal remote controller display.

button to return to normal remote controller display.