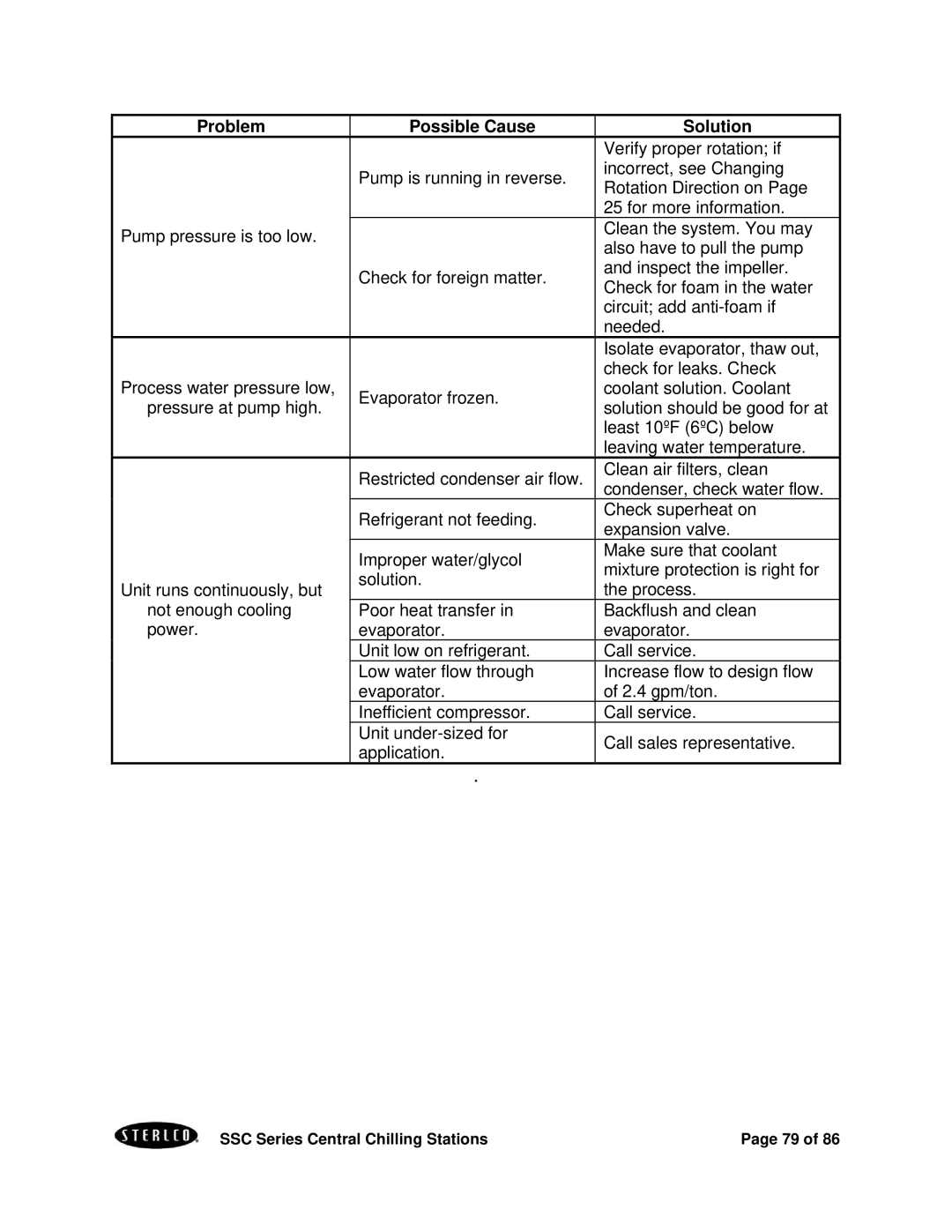

Problem | Possible Cause | Solution | |

|

| Verify proper rotation; if | |

| Pump is running in reverse. | incorrect, see Changing | |

| Rotation Direction on Page | ||

|

| ||

|

| 25 for more information. | |

Pump pressure is too low. |

| Clean the system. You may | |

| also have to pull the pump | ||

|

| ||

| Check for foreign matter. | and inspect the impeller. | |

| Check for foam in the water | ||

|

| ||

|

| circuit; add | |

|

| needed. | |

|

| Isolate evaporator, thaw out, | |

Process water pressure low, |

| check for leaks. Check | |

Evaporator frozen. | coolant solution. Coolant | ||

pressure at pump high. | solution should be good for at | ||

| |||

|

| least 10ºF (6ºC) below | |

|

| leaving water temperature. | |

| Restricted condenser air flow. | Clean air filters, clean | |

| condenser, check water flow. | ||

|

| ||

| Refrigerant not feeding. | Check superheat on | |

| expansion valve. | ||

|

| ||

| Improper water/glycol | Make sure that coolant | |

| mixture protection is right for | ||

| solution. | ||

Unit runs continuously, but | the process. | ||

| |||

not enough cooling | Poor heat transfer in | Backflush and clean | |

power. | evaporator. | evaporator. | |

| Unit low on refrigerant. | Call service. | |

| Low water flow through | Increase flow to design flow | |

| evaporator. | of 2.4 gpm/ton. | |

| Inefficient compressor. | Call service. | |

| Unit | Call sales representative. | |

| application. | ||

|

|

.

SSC Series Central Chilling Stations | Page 79 of 86 |