Two hourmeters are kept for each compressor in the system. The first is a lifetime meter. This measures the total time that the pump has been operational in the lifetime of the chiller. The second is a resettable hourmeter. This hourmeter can be cleared to monitor run time on specific intervals. In order to clear the resettable hourmeter, press the F1 button (as prompted on the screen)

7-6 Viewing Active Alarms and Handling Alarm Conditions

These two screens let you view any active alarm conditions as well as the alarm history for the entire history. The list of system alarms that are tracked are as follows:

nChilled Water High Temperature Alarm

nChilled Water Low Temperature Alarm

nCompressor Motor Protector Fault (One for each compressor)

nChilled Water Circuit Low Flow (One per chilled water circuit)

nChilled Water Circuit Freezestat (One per chilled water circuit)

nChilled Water Circuit High Pressure (One per chilled water circuit)

nChilled Water Circuit Low Pressure (One per chilled water circuit)

nPump motor overload (One per system pump)

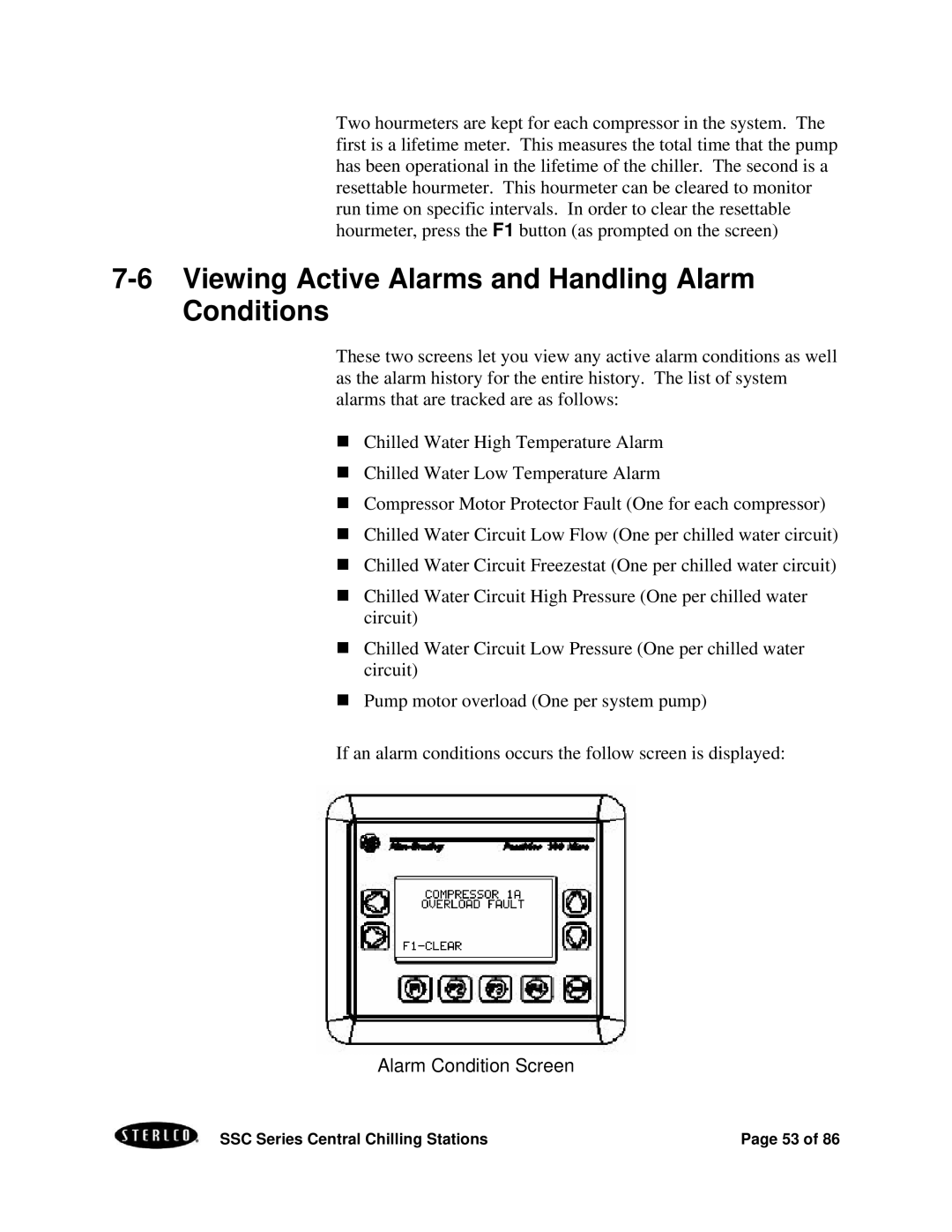

If an alarm conditions occurs the follow screen is displayed:

Alarm Condition Screen

SSC Series Central Chilling Stations | Page 53 of 86 |