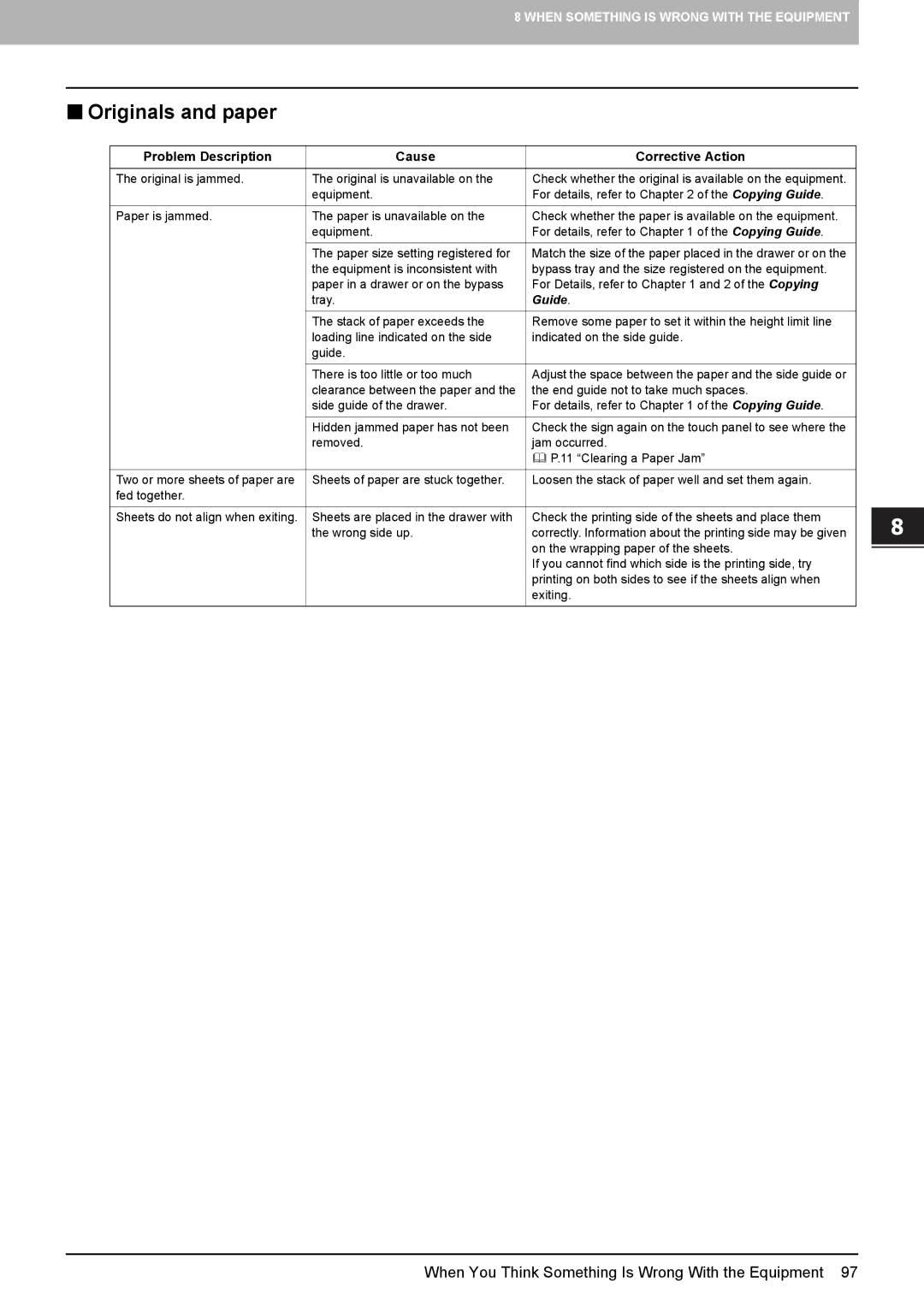

8 WHEN SOMETHING IS WRONG WITH THE EQUIPMENT

Originals and paper

Problem Description | Cause | Corrective Action |

|

|

|

The original is jammed. | The original is unavailable on the | Check whether the original is available on the equipment. |

| equipment. | For details, refer to Chapter 2 of the Copying Guide. |

|

|

|

Paper is jammed. | The paper is unavailable on the | Check whether the paper is available on the equipment. |

| equipment. | For details, refer to Chapter 1 of the Copying Guide. |

|

|

|

| The paper size setting registered for | Match the size of the paper placed in the drawer or on the |

| the equipment is inconsistent with | bypass tray and the size registered on the equipment. |

| paper in a drawer or on the bypass | For Details, refer to Chapter 1 and 2 of the Copying |

| tray. | Guide. |

|

|

|

| The stack of paper exceeds the | Remove some paper to set it within the height limit line |

| loading line indicated on the side | indicated on the side guide. |

| guide. |

|

|

|

|

| There is too little or too much | Adjust the space between the paper and the side guide or |

| clearance between the paper and the | the end guide not to take much spaces. |

| side guide of the drawer. | For details, refer to Chapter 1 of the Copying Guide. |

|

|

|

| Hidden jammed paper has not been | Check the sign again on the touch panel to see where the |

| removed. | jam occurred. |

|

| P.11 “Clearing a Paper Jam” |

|

|

|

Two or more sheets of paper are | Sheets of paper are stuck together. | Loosen the stack of paper well and set them again. |

fed together. |

|

|

|

|

|

Sheets do not align when exiting. | Sheets are placed in the drawer with | Check the printing side of the sheets and place them |

| the wrong side up. | correctly. Information about the printing side may be given |

|

| on the wrapping paper of the sheets. |

|

| If you cannot find which side is the printing side, try |

|

| printing on both sides to see if the sheets align when |

|

| exiting. |

|

|

|

When You Think Something Is Wrong With the Equipment 97